Struggling with fluctuating water pressure?

A traditional pump system can cause annoying surges and drops.

This instability damages plumbing and ruins your water experience.

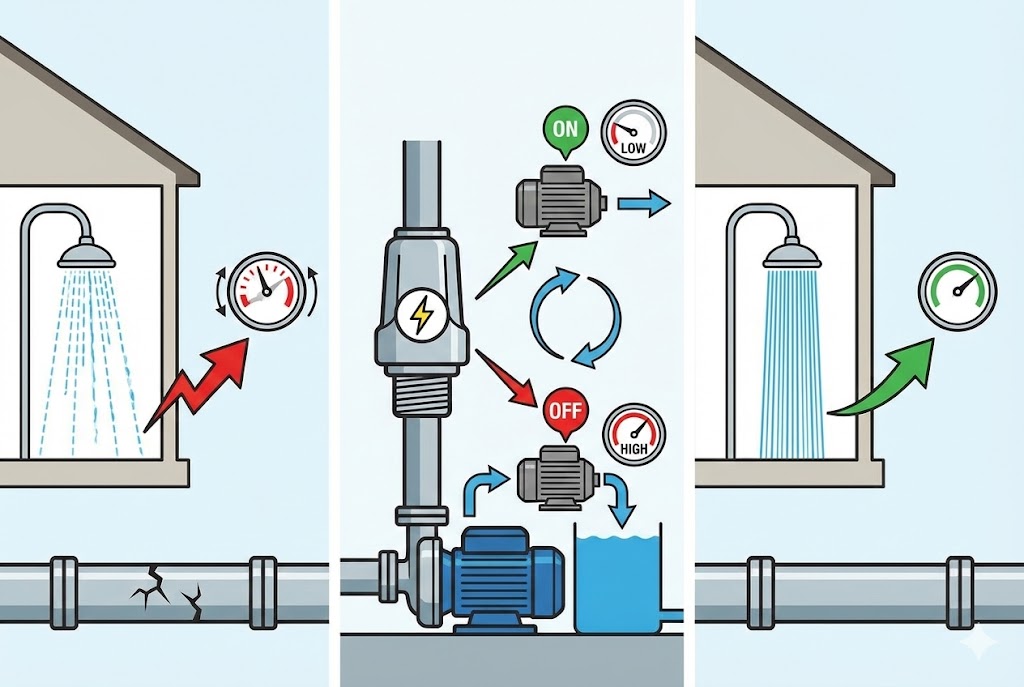

A pressure switch is the brain of a booster pump system.

It's an automated component that senses water pressure.

The switch turns the pump on when pressure is low and off when it's high.

This cycle ensures consistent pressure and protects the pump from damage.

A pressure switch is a small but vital part of any standard water booster pump setup.

It acts as a simple, automated controller.

Its job is to maintain water pressure within a specific range, without needing you to manually turn the pump on or off.

Understanding how this mechanical device works is the first step.

Next, we will explore its core functions and limitations.

This knowledge reveals why modern pump systems are moving toward more advanced, integrated electronic controls.

These newer systems provide far greater efficiency, protection, and user comfort.

How it works

Is your pump's constant cycling driving up energy bills?

This on-off action is inefficient.

It also puts unnecessary mechanical stress on the entire system.

A pressure switch operates using a simple mechanical system.

Inside, a diaphragm reacts to water pressure changes.

This movement controls an electrical contact, telling the pump when to start and stop, maintaining pressure within a pre-set range.

The Mechanical Process of a Pressure Switch

The operation of a traditional pressure switch is purely mechanical.

It relies on a few key internal components to function.

Water from the system presses against a flexible diaphragm.

This diaphragm is connected to a lever and a set of springs.

The tension on these springs determines the pressure points for turning the pump on and off.

Sensing Pressure and Activating the Pump

When you open a tap, water flows out of the system.

This causes the pressure inside the pipes to drop.

As the pressure falls, the force on the diaphragm lessens.

Eventually, the pressure reaches a low point called the "cut-in" pressure.

At this point, the spring pushes the lever down.

This action closes a set of electrical contacts.

Completing the circuit sends power directly to the pump's motor, turning it on.

The pump then begins to move water, increasing the system pressure.

Deactivating the Pump

As the pump runs, it fills the pipes and pressure tank, if one is installed.

The water pressure in the system starts to build.

This increasing pressure pushes back against the diaphragm inside the switch.

When the pressure reaches the high point, known as the "cut-out" pressure, it overcomes the spring tension.

The diaphragm pushes the lever system upward.

This movement forces the electrical contacts to open.

The circuit is broken, and the power to the pump motor is cut off.

The pump stops running until the pressure drops to the cut-in level again.

This entire cycle repeats automatically whenever water is used.

| Component | Function |

|---|---|

| Diaphragm | Senses the water pressure and moves in response. |

| Springs | Provide adjustable tension to set cut-in and cut-out pressures. |

| Lever System | Transfers movement from the diaphragm to the electrical contacts. |

| Electrical Contacts | Open or close to control the flow of electricity to the pump motor. |

The Role of Pressure Differential

The difference between the cut-in and cut-out pressures is critical.

This range is known as the "pressure differential."

It is often set at around 20 PSI (1.4 bar) for residential systems.

For example, a switch might be set to turn the pump on at 30 PSI and off at 50 PSI.

A narrow differential causes the pump to cycle on and off frequently, which is called short-cycling.

Short-cycling leads to increased wear on the pump motor and switch contacts.

It also consumes more energy.

A wider differential reduces cycling but results in a more noticeable pressure fluctuation at the tap.

The Limits of Mechanical Switches

While effective, this mechanical system has limitations.

The sudden start and stop of the motor create a surge of electrical current.

It also causes hydraulic shock, known as water hammer.

These jolts can damage the pump, the pipes, and other connected appliances over time.

Modern pumps address these issues with advanced electronic controls.

These systems use variable frequency drives (VFDs) and sophisticated sensors.

Instead of a harsh on/off cycle, a VFD pump adjusts its motor speed in real-time.

It runs only as fast as needed to maintain a perfectly constant pressure.

This "soft start" and "soft stop" functionality eliminates electrical and mechanical shocks.

It results in smoother, quieter operation, significant energy savings, and a much longer lifespan for the entire water system.

Key functions

Are you concerned about your pump overheating?

Running continuously or against a blockage can cause serious damage.

A basic pump lacks the intelligence to protect itself from these common faults.

A pressure switch provides automation and protection.

It automates the pump's on-off cycle to maintain a consistent pressure range.

Critically, it also protects the pump from overheating by preventing it from running unnecessarily when demand ceases.

Automation of the Pump Cycle

The primary function of a pressure switch is automation.

It removes the need for any manual intervention to operate the pump.

Without it, you would have to physically turn the pump on every time you needed water.

You would also have to turn it off when you were finished.

This simple automated cycle is the foundation of modern pressurized water systems.

It ensures water is available on demand.

The switch works day and night to keep the system ready.

System Protection

A key secondary function is protecting the pump motor.

Pumps are designed to move water, which also helps cool the motor.

If a pump runs continuously with no water flowing (a "dead head" situation), it will quickly overheat.

This can lead to catastrophic motor failure.

The pressure switch prevents this scenario.

When all taps are closed, pressure builds rapidly to the cut-out point.

The switch then cuts power, stopping the pump.

This simple action protects the motor from burnout and extends its operational life.

It is a basic but essential form of protection.

Maintaining System Pressure

The switch is also responsible for regulating pressure.

It works to keep the water pressure within the predefined cut-in and cut-out range.

This provides a more consistent user experience than a pump that is either fully on or fully off manually.

However, the pressure still fluctuates.

Users will notice the pressure dropping just before the pump kicks in.

They will also feel it rise while the pump is running.

This is an inherent characteristic of systems controlled by a traditional pressure switch.

To minimize this fluctuation, a pressure tank is often installed.

The tank stores a reserve of pressurized water.

This reserve can satisfy small water demands without needing the pump to start.

This reduces the number of start/stop cycles, or "short-cycling," which further protects the motor.

The Evolution to Intelligent Protection

While a mechanical switch provides basic protection, it is not intelligent.

It cannot detect many common and damaging fault conditions.

This is where modern, electronically controlled pumps have a significant advantage.

They integrate a comprehensive suite of advanced protection functions that go far beyond what a simple switch can offer.

Advanced Electronic Safeguards

Modern pumps use sophisticated sensors and microprocessors to monitor conditions in real-time.

This allows for a level of protection that is impossible with a mechanical switch.

These systems often include a "14-Shield" or similar multi-layer protection strategy.

Key Electronic Protections:

- Dry Run Protection: The system can detect when there is no water to pump. Instead of running until it burns out, it will stop and enter a timed recovery mode, periodically checking for water to return.

- Voltage Protection: It constantly monitors input voltage. If the voltage is too high or too low, the pump will shut down to protect its sensitive electronics.

- Overheating Protection: Multiple sensors monitor the temperature of the motor, the drive board, and even the water itself. If any part exceeds safe limits, the pump will stop to prevent damage.

- Antifreeze Protection: In cold climates, the pump can automatically run for a few moments if the temperature drops near freezing, preventing ice from forming and cracking the pump body.

- Leak Detection: The system can intelligently detect minor, persistent pressure drops characteristic of a pipeline leak. It can then alert the user to the potential problem before it causes significant water loss or damage.

These intelligent features fundamentally change the role of the pump controller.

It evolves from a simple on/off switch into a comprehensive system manager.

This manager actively safeguards the equipment, conserves energy, and ensures long-term reliability.

The result is a smarter, more durable, and more efficient water pressure solution.

Conclusion

A pressure switch is a basic pump controller.

It automates the on-off cycle for pressure.

Modern VFD pumps offer superior control, protection, and efficiency for today's needs.

FAQs

What happens if a pressure switch fails?

If a pressure switch fails, it can either get stuck "on" or "off."

If stuck on, the pump runs continuously, risking damage.

If stuck off, the pump won't turn on, resulting in no water pressure.

How do I know if my pressure switch is bad?

Signs of a bad pressure switch include the pump not turning on, the pump not turning off, or rapid, constant clicking (short-cycling).

Water pressure may also be very low or non-existent.

Can you adjust a pump pressure switch?

Yes, most mechanical pressure switches are adjustable.

They typically have two nuts inside the cover.

One adjusts the cut-in/cut-out range together, and the other adjusts the differential between them.

What is the difference between a pressure switch and a pressure transducer?

A pressure switch is a mechanical on/off device triggered by set pressure points.

A pressure transducer is an electronic sensor that provides a continuous, variable signal corresponding to the exact real-time pressure.

At what pressure should a water pump cut in and out?

For most homes, a common setting is 30-50 PSI or 40-60 PSI.

The pump cuts in at the lower number and cuts out at the higher number.

The ideal range depends on the system and homeowner preference.

What causes a pressure switch to burn out?

Common causes include rapid cycling (short-cycling), which wears out the contacts, corrosion from moisture, and electrical surges.

An incorrectly sized pump or a failed pressure tank can also contribute to burnout.