Struggling with weak showers or inconsistent water flow?

Your home's water pressure might be too low.

A booster pump can solve this, but what pressure is correct?

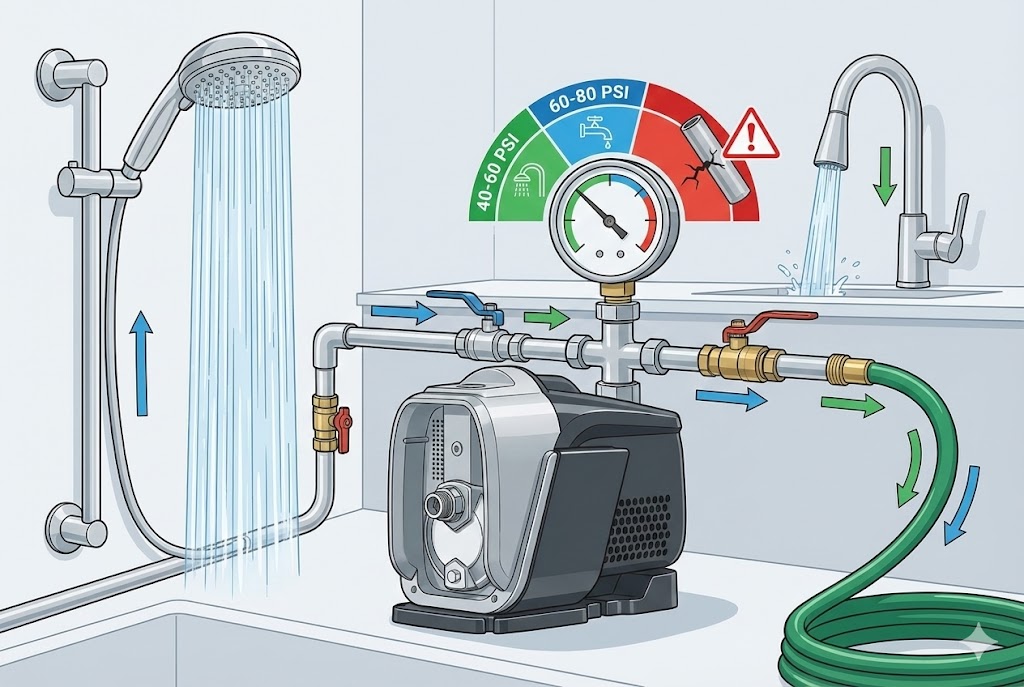

The normal operating pressure for a residential booster pump is between 40 and 80 PSI. Ideally, for most homes, a range of 60 to 80 PSI provides strong flow for all fixtures without risking damage to your plumbing system, which can occur if pressure exceeds 80 PSI.

Understanding water pressure is simple.

It is the force that pushes water through your pipes.

Finding the right balance is key for a happy home and healthy plumbing.

Too little pressure means frustratingly weak showers.

Too much pressure can lead to leaks, burst pipes, and damaged appliances.

This guide will walk you through everything you need to know.

We will explore the common pressure ranges.

We will also look at how to determine the right pressure for your specific needs, from single-family homes to multi-story buildings.

We will even dive deep into the advanced technology that makes modern booster pumps so smart and reliable.

Let's explore how to achieve perfect water pressure.

Common Pressure Ranges

Is your water pressure causing problems?

Low pressure can make daily tasks a chore, while high pressure silently damages your home's pipes.

Understanding the right range is the first step.

A booster pump's pressure should be set to an ideal range of 60-80 PSI for most homes. An acceptable range is 40-60 PSI, but anything above 80 PSI is generally considered too high and can risk damaging pipes, fittings, and connected appliances over time.

Choosing the right pressure isn't just about comfort.

It's about protecting your investment.

Your home's entire plumbing system, from the pipes hidden in the walls to your washing machine and dishwasher, is designed to operate within a specific pressure window.

Operating outside this window can lead to premature failure and costly repairs.

Modern booster pumps offer precise control, but you need to know what target to set.

Defining Pressure Levels

Let's break down what these pressure numbers mean for your home.

Think of it like a tiered system.

-

Ideal Pressure (60-80 PSI): This is the sweet spot. It provides a strong, satisfying flow for multiple fixtures at once. You can run a shower, a dishwasher, and a faucet without a noticeable drop in performance. This range delivers the experience most homeowners expect.

-

Acceptable Pressure (40-60 PSI): This range is functional. It will get the job done for most single-story homes with standard needs. However, you might notice a drop in flow when multiple fixtures are used simultaneously. It's a common range but may feel inadequate in larger homes.

-

Maximum Recommended Pressure (75-80 PSI): This is the upper limit for typical residential plumbing. Pushing beyond this point puts excessive strain on pipe joints, seals, and appliance inlet valves. While some systems can handle it, it's not recommended without professional consultation, as it significantly increases the risk of leaks and bursts.

Pressure Switch Settings

Many booster pumps use a pressure switch.

This device creates an operating range for the pump.

It has two key settings:

- Cut-In Pressure: This is the low-pressure point that signals the pump to turn on. For example, if the cut-in is set to 40 PSI, the pump will start working as soon as the system pressure drops to that level.

- Cut-Out Pressure: This is the high-pressure point that tells the pump to turn off. Once the system reaches this pressure, for instance 60 PSI, the pump shuts down to prevent over-pressurization and save energy.

This 40/60 PSI setting is a very common factory default.

It creates a 20 PSI differential, ensuring the pump doesn't cycle on and off too frequently, which can cause premature wear.

A properly configured pressure switch is crucial for maintaining your desired pressure range automatically.

How to Determine the Right Pressure

Struggling to find the perfect water pressure for your home?

Setting it too low leads to weak flow, while setting it too high risks damaging your pipes.

Finding the correct balance is key.

To determine the right pressure, consider your home's size and fixtures. Most residential homes are perfectly served by 40-80 PSI. However, multi-story homes require higher pressure to push water upwards, and you must always respect the system's limits set by the pressure switch.

There isn't a single magic number for every house.

Your neighbor's ideal setting might not be right for you.

Factors like the height of your building, the age of your pipes, and the types of appliances you own all play a role.

A thoughtful approach ensures you get the powerful showers you want without creating a ticking time bomb in your walls.

Let's break down the key considerations to help you find the perfect pressure setting for your specific situation.

Residential Applications

For most standard homes, the 40-80 PSI range is the gold standard.

Why?

Because manufacturers design residential fixtures and appliances with this pressure in mind.

- Toilets: Require sufficient pressure to fill quickly and flush effectively.

- Showers: Modern showerheads, especially rain and multi-jet types, need good pressure for a satisfying experience.

- Washing Machines & Dishwashers: Rely on adequate pressure to fill within their timed cycles and operate efficiently.

- Faucets: A strong, steady stream is expected for everything from washing hands to filling pots.

Staying within this range ensures compatibility and longevity for all your water-using devices.

Multi-Story Homes and Elevation

Gravity is a major factor in water pressure.

For every 10 feet of vertical height you need to push water, you lose about 4.3 PSI of pressure.

Consider a three-story home.

The bathroom on the top floor could be 20-30 feet above the booster pump.

This elevation change alone can cause a pressure drop of 8.6 to 12.9 PSI by the time water reaches the top floor faucet.

This is where a higher setting on your booster pump becomes necessary.

If your ground floor has 60 PSI, the top floor might only have about 50 PSI.

To ensure the top floor has adequate pressure (e.g., 50-60 PSI), you might need to set your booster pump's cut-out pressure closer to 70 or 75 PSI.

This compensates for the pressure lost due to gravity.

System Limits and Pressure Switches

Every pump system has built-in limits.

These are managed by the pressure switch, which acts as the brain of the operation.

The switch dictates the 'on' (cut-in) and 'off' (cut-out) pressures.

For example, a common setting is a "30/50" switch.

| Setting | Pressure (PSI) | Action |

|---|---|---|

| Cut-In | 30 | The system pressure has dropped, so the pump turns ON. |

| Cut-Out | 50 | The system has reached target pressure, so the pump turns OFF. |

The difference between these two numbers is called the pressure differential.

A wider differential (e.g., 30/60) means the pump will run for longer but cycle on and off less frequently, which can extend the motor's life.

A narrower differential (e.g., 40/50) provides more consistent pressure but causes more frequent cycling.

It is critical not to set the cut-out pressure higher than the maximum rating of your pipes, tank, or appliances.

Professional Advice

When in doubt, always consult a professional.

A qualified plumber can assess your entire system accurately.

They will consider:

- The age and material of your pipes (e.g., copper, PEX, galvanized steel).

- The height and layout of your home.

- The specific requirements of your appliances.

- The condition of your pressure tank.

A plumber can use a pressure gauge to get precise readings at various points in your home.

This data allows them to recommend the absolute best pressure settings for both performance and safety.

Investing in a professional consultation can save you thousands in potential damage from an improperly set system.

Core Drive Technology and Performance

Are you tired of pumps that are noisy and unreliable?

Old technology leads to fluctuating pressure and high energy bills, making your system inefficient.

It is time for a smarter solution.

Modern booster pumps use a Permanent Magnet Synchronous Motor (PMSM) with a Variable Frequency Drive (VFD). This combination provides whisper-quiet operation, completely stable water pressure, and significant energy savings by precisely matching pump speed to water demand.

The engine at the heart of an advanced booster pump is what sets it apart.

The synergy between a high-efficiency motor and an intelligent drive controller transforms performance.

Instead of a simple on/off switch, this technology constantly adjusts, delivering exactly the pressure you need, when you need it.

This a smart, responsive system that enhances comfort, saves money, and protects your plumbing from stress.

Let's dive deeper into how this powerful core technology works.

Key Performance Advantages

The combination of a Permanent Magnet Synchronous Motor (PMSM) and a Variable Frequency Drive (VFD) delivers a superior user experience.

This isn't just a minor upgrade; it's a fundamental change in how water pressure is managed.

Silent Operation

The primary complaint with traditional pumps is noise.

They clunk on and shudder off, creating vibrations throughout the house.

Advanced VFD systems eliminate this.

The precise electronic control of the motor and its high-quality construction result in noise levels below 50 decibels.

That's quieter than a library or a soft conversation, meaning you might not even know the pump is running.

Constant, Customizable Pressure

Old pumps work in a range, like 40 to 60 PSI.

You can feel the pressure drop as it nears the lower limit.

A VFD pump eliminates this fluctuation.

If you set the pressure to 60 PSI, it delivers exactly 60 PSI whether one faucet is on or three.

The drive adjusts the motor's speed in real-time to maintain that constant pressure.

Furthermore, these systems offer a wide adjustment range, allowing you to set the pressure anywhere from 20% to 95% of the pump's maximum capability.

This provides incredible flexibility for different applications.

Soft Start and Stop

When a traditional pump kicks on, it goes from zero to full speed instantly.

This sudden jolt sends a shockwave, known as water hammer, through your pipes.

This stresses joints and can cause leaks over time.

VFD technology enables a "soft start" and "soft stop."

The controller gradually ramps the motor's speed up and down.

This smooth acceleration and deceleration eliminates water hammer, drastically reducing mechanical stress on the pump and the entire plumbing system.

This single feature significantly contributes to a longer, trouble-free lifespan for your pipes and appliances.

Excellence in Mechanical and Material Engineering

Worried about a pump that will fail after just a few years?

Pumps built with cheap plastic parts and standard components often break down prematurely, leading to costly replacements.

Quality materials are not a luxury.

Top-tier booster pumps demonstrate a commitment to longevity through superior materials. This includes using AISI304 stainless steel for impellers, high-grade silicon steel in the motor, and premium bearings from trusted manufacturers like NSK or C&U for durable, efficient, and quiet operation.

A pump is more than just its motor.

It is a complex mechanical system where every single component matters.

The difference between a pump that lasts three years and one that lasts for over a decade often comes down to the quality of the materials used in its construction.

From the stator windings to the bearings and the impeller, investing in quality engineering ensures reliability, efficiency, and peace of mind.

Let's examine the internal components that define a truly well-built booster pump.

Advanced Stator and Rotor Design

The stator and rotor are the heart of the electric motor.

Their design and materials directly impact efficiency and durability.

A superior pump will feature a meticulously engineered stator.

| Stator Component | Material/Specification | Benefit |

|---|---|---|

| Core Material | 600-Grade Silicon Steel | Reduces electrical losses, boosting motor efficiency. |

| Thermal Rise | Low Temperature Rise (≤50K) | Shows excellent heat management, leading to a longer motor life. |

| Insulation | Class F Insulation Wire | Resists high temperatures, ensuring reliability under heavy loads. |

| Safety | Dual Insulation | Provides an extra layer of protection against electrical faults. |

The motor's rotor is equally important.

High-performance designs utilize an advanced ferrite magnet.

This material is chosen for its ability to withstand high temperatures (up to 150°C) without losing its magnetic properties, which is crucial for consistent performance over the pump's lifetime.

Some advanced models also offer an EMC+PFC configuration.

This ensures the pump doesn't interfere with other electronics (Electromagnetic Compatibility) and uses electricity more efficiently (Power Factor Correction), which is often required to meet strict international electrical standards.

Premium Bearings and Hydraulics

The smallest parts can often make the biggest difference.

Bearings are a perfect example.

While they are a small component, they are under constant stress.

Using high-quality bearings from world-renowned manufacturers ensures smoother and quieter operation.

These premium bearings can offer:

- 16% higher precision in their manufacturing.

- 40% quieter operation compared to standard alternatives.

- An 11% longer operational lifespan.

The hydraulic core of the pump, the part that actually moves the water, is just as critical.

The impeller is the spinning wheel that throws water outward, creating pressure.

Using AISI304 stainless steel for the impeller is a hallmark of quality.

This material offers exceptional resistance to corrosion and wear, even with aggressive water or high temperatures.

It will not rust or degrade like cheaper plastic or cast iron impellers, ensuring the pump's hydraulic performance remains consistent for years.

Uncompromising Electronic Reliability

Is your pump's control board exposed to the elements?

Moisture, dust, and vibration are the enemies of electronics, causing 95% of controller failures and leading to unexpected breakdowns.

A simple plastic cover is not enough protection.

The most reliable booster pumps protect their electronics with full PCB potting. This process completely seals the main controller board in a waterproof, dustproof, and shock-resistant compound, achieving an IP67 rating and extending the controller's life by 3 to 5 years.

A booster pump's intelligence lives on its Printed Circuit Board (PCB).

This is the brain that controls the motor, monitors sensors, and protects the system.

Unfortunately, pumps often operate in damp, dusty basements or outdoor sheds—the worst possible environments for sensitive electronics.

The most significant advancement in ensuring long-term reliability is isolating this electronic brain from the harsh environment it lives in.

Let's explore why this potting technique is a game-changer for pump durability.

The Power of Full Potting

Potting is a process where the entire electronic circuit board and its components are encased in a solid, protective material, like an epoxy or silicone resin.

This creates an impenetrable fortress for the electronics.

Total Environmental Protection

A potted controller achieves an IP67 protection rating.

This rating has a specific meaning:

- The '6' means it is completely sealed against dust ingress. No dust or debris can get inside to short out components.

- The '7' means it is waterproof even when submerged in up to 1 meter of water for 30 minutes.

This makes the electronics impervious to the most common causes of failure:

- Moisture and Condensation: In damp basements or humid climates, moisture can form on unprotected boards, causing short circuits. Potting eliminates this risk entirely.

- Dust and Debris: Conductive dust can settle on circuits and cause failures. A potted board is completely sealed.

- Vibration and Shock: The solid potting compound holds every component securely in place, preventing connections from vibrating loose over time.

The Long-Term Benefits

This level of protection directly translates into a longer, more reliable service life.

By preventing the vast majority of moisture-related failures, this feature is projected to extend the controller's lifespan by 3 to 5 years compared to a non-potted board.

This is not just about convenience; it's about total cost of ownership.

A pump that doesn't suffer from premature electronic failure saves you the cost and hassle of service calls and replacements.

While it is a more expensive manufacturing process, it is a critical investment in reliability.

When evaluating a modern booster pump, asking whether the main controller is fully potted is one of the most important questions you can ask.

It is a clear indicator of the manufacturer's commitment to building a product that is designed to last.

Intuitive User Interface and Real-Time Monitoring

Are you intimidated by complex pump controls and confusing manuals?

Many powerful devices are hard to use, with cryptic codes and hidden menus that make simple adjustments a frustrating task.

You need power that is easy to control.

A well-designed booster pump combines advanced functionality with a simple, intuitive user interface. It should feature clear buttons for on/off and pressure adjustment, along with bright LED indicators that provide at-a-glance status updates on pressure, power, and system health.

What good is advanced technology if you can't easily use it?

Despite the sophisticated engineering inside, the daily operation of a modern booster pump should be effortless.

A smart interface provides transparency, giving you both simple controls for everyday use and access to detailed data when you need it.

This user-centric design philosophy ensures you are always in control and fully aware of your system's performance, without needing an engineering degree.

Simple Controls, Deep Data

An effective interface balances simplicity with access to information.

The best systems achieve this through a combination of straightforward buttons and a multi-function display.

Everyday Operation

Basic functions should be obvious and require no instruction manual.

- On/Off: A single, short press of a dedicated power button.

- Pressure Adjustment: Simple UP and DOWN arrow buttons to increase or decrease the target pressure in small, precise increments.

- Factory Reset: A common function is a long press of the power button (e.g., 3 seconds) to restore the pump to its original settings.

At-a-Glance Indicators

You shouldn't have to guess what the pump is doing.

A series of dedicated LED lights provides immediate visual feedback.

| LED Indicator | Status Meaning |

|---|---|

| Constant Pressure | Lit when the pump is actively maintaining the set pressure. |

| Pipeline Leakage | Flashes or lights up to warn of a potential leak in the system. |

| Water Shortage | Indicates the pump has stopped due to lack of water (dry run). |

| Voltage Fault | Warns that the input voltage is too high or too low. |

| Power Level | A bar graph showing the current power output of the pump. |

This visual dashboard lets you understand the pump's status from across the room.

Accessing Real-Time Diagnostics

For advanced users or technicians, having access to live operating data is invaluable for diagnostics and system optimization.

A well-designed interface allows you to cycle through critical parameters with a simple command, such as a long press of a specific button.

This can reveal a wealth of information:

- A.xx: Current water temperature.

- P.xxx: Real-time power consumption in watts.

- xxxx: Current motor speed in RPM.

- U.xxx: Current input voltage from the grid.

- t.xx: Temperature of the main PCB controller.

- Recovery Pressure: The pressure level set for restarting after sleep mode.

This ability to see inside the machine's operation in real-time transforms troubleshooting from guesswork into a data-driven process.

It helps identify issues not just with the pump, but with the entire water system, such as voltage sags or potential overheating problems.

Conclusion

Ultimately, the right booster pump pressure is a balance.

It's about achieving powerful flow for your home while ensuring the long-term safety and integrity of your entire plumbing system.

FAQs

What pressure is too low for a house?

Water pressure below 40 PSI is generally considered too low. It can lead to weak showers, slow-filling appliances, and poor performance from multiple fixtures used at once.

Can a booster pump be too powerful?

Yes. A pump that creates pressure over 80 PSI can stress pipes, joints, and appliance seals. This significantly increases the risk of leaks, bursts, and premature system failure.

Does a booster pump run all the time?

No. A modern booster pump, especially a VFD model, only runs when there is water demand. It will shut off or enter a standby mode when all faucets are closed to save energy.

How do you test water pressure?

You can test water pressure with a simple pressure gauge. These are inexpensive and screw directly onto an outdoor hose spigot to give you an instant reading of your home's static pressure.

How do I increase my water pressure?

The most effective way to increase water pressure is by installing a booster pump. If you already have one, you can adjust its pressure switch or settings to a higher, safe level.

What is the difference between water pressure and water flow?

Pressure is the force pushing the water, measured in PSI. Flow is the volume of water delivered over time, measured in gallons per minute (GPM). They are related but not the same.

Is 100 PSI too high for a house?

Yes, 100 PSI is dangerously high for standard residential plumbing. It can cause catastrophic failure of pipes and appliances and should be reduced immediately with a pressure reducing valve.

Should I turn off my booster pump at night?

No, it is not necessary. A modern booster pump automatically enters a standby mode when there is no water use, consuming very little power. It is designed to be on 24/7.