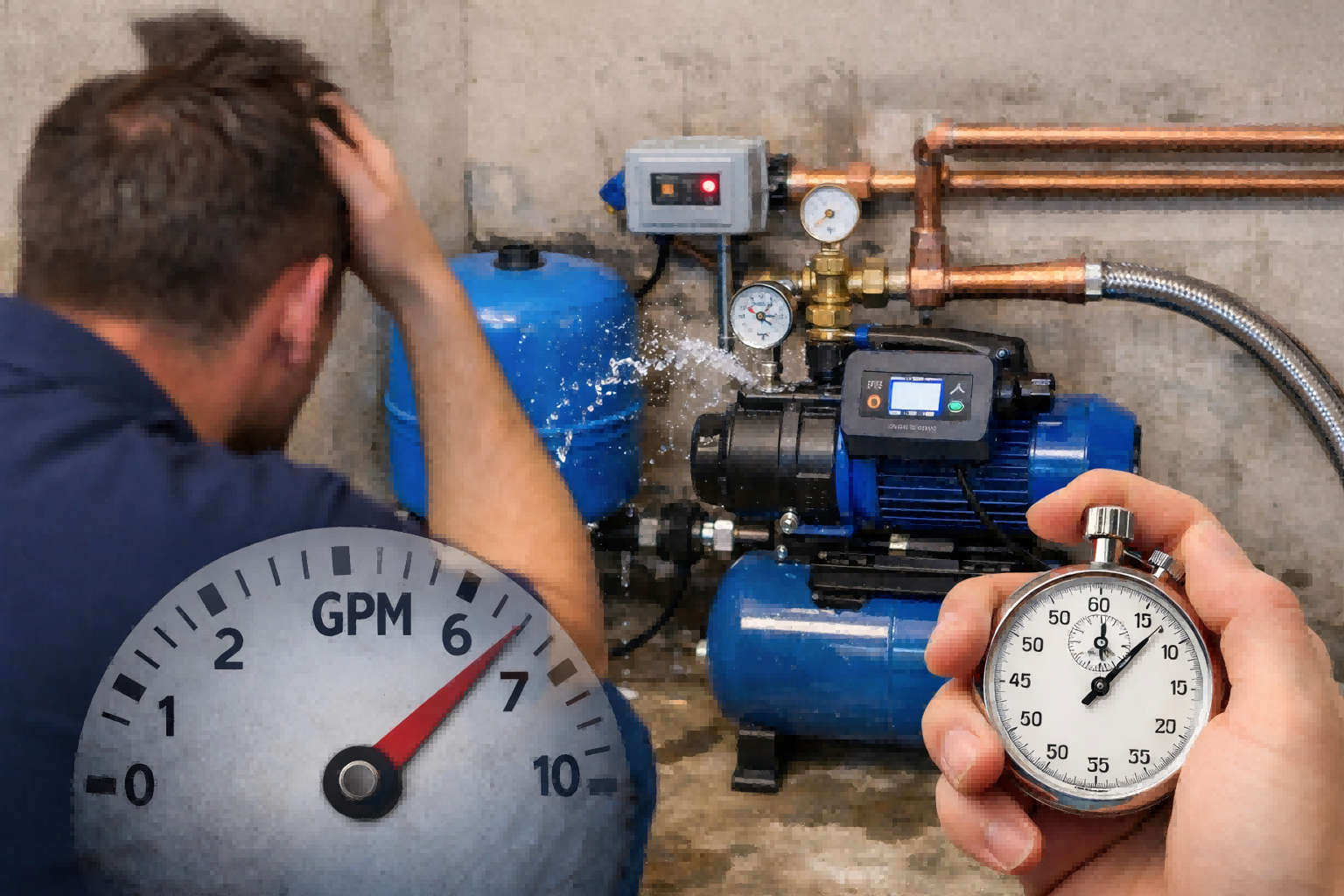

Is your pump constantly turning on and off?

This frequent cycling wears out your pump and wastes energy.

Choosing the wrong size pressure tank is often the cause of this problem.

To size a pressure tank, you need to know your pump's flow rate in gallons per minute (GPM) and your pressure switch settings.The goal is to provide a minimum one-minute runtime for the pump to prevent rapid cycling, which protects the motor and saves energy.

Getting the tank size right is crucial for the health and efficiency of your entire water system.

A tank that is too small will cause the pump to cycle excessively, leading to premature motor burnout and higher electricity bills.

A tank that is too large can be a waste of money and space, though it is generally better to oversize than to undersize.

This is especially true for modern off-grid systems, such as solar-powered well pumps.

In these setups, the pressure tank plays an even more vital role.

It acts as a water battery, storing water pumped during peak sun hours for use at any time.

Let's break down the factors you need to consider to get the sizing perfect.

What Are the Core Sizing Factors?

Struggling to figure out where to even start with tank sizing?

The numbers and terms can seem confusing.

You risk buying the wrong equipment if you don't understand the basics.

The three core factors for sizing a pressure tank are the pump's flow rate (GPM), the pressure switch settings (cut-in and cut-off PSI), and the tank's resulting drawdown capacity.

Before you can choose a tank, you must understand the relationship between your pump and the tank itself.

The pressure tank doesn't store a full tank's worth of usable water.

It stores water under pressure within a specific range.

The amount of water it delivers between the pump turning on and turning off is called "drawdown."

This drawdown is what you are really sizing for.

Pump Flow Rate

The first and most important number you need is your pump's flow rate.

This is measured in gallons per minute (GPM) or liters per minute (LPM).

You can usually find this information on the pump's label or in its manual.

If you don't know the flow rate, you can measure it.

Simply time how long it takes for the pump to fill a bucket of a known size (e.g., a 5-gallon bucket).

A pump with a higher flow rate will require a larger pressure tank to achieve the desired one-minute runtime.

For example, a 10 GPM pump needs a tank that can provide 10 gallons of drawdown.

Pressure Switch Settings

The pressure switch tells the pump when to turn on and when to turn off.

It has two settings:

- Cut-In Pressure: The low-pressure point (in PSI) at which the pump turns on.

- Cut-Off Pressure: The high-pressure point (in PSI) at which the pump turns off.

Common settings are 30/50 PSI, 40/60 PSI, or 50/70 PSI.

This pressure range directly affects the tank's drawdown.

A wider pressure differential (e.g., 30/50 PSI, a 20 PSI difference) results in more drawdown from the same size tank compared to a narrower range (e.g., 40/50 PSI, a 10 PSI difference).

Tank Drawdown Explained

Drawdown is the actual amount of usable water a pressure tank delivers.

It is determined by the tank's total volume, its pre-charge pressure, and the system's pressure switch settings.

Manufacturers provide drawdown charts that show how much water a specific tank model will provide under different pressure settings.

| Tank Total Volume (Gallons) | Pressure Setting | Drawdown (Gallons) |

|---|---|---|

| 20 | 30/50 PSI | 6.5 |

| 20 | 40/60 PSI | 5.5 |

| 44 | 30/50 PSI | 14.2 |

| 44 | 40/60 PSI | 11.9 |

As the table shows, a larger tank or a wider pressure range increases the drawdown, which in turn reduces pump cycling.

How Do You Size for a Standard Well System?

Need a straightforward way to calculate the right tank size?

Guessing could lead to buying a tank that is too small.

This would create the exact problem you are trying to solve.

**For a standard well pump, a simple rule is to match the tank's drawdown capacity to the pump's flow rate.

A 10 GPM pump needs a tank with a drawdown of 10 gallons.**

In a conventional grid-powered well system, the primary goal of the pressure tank is to protect the pump motor.

Electric motors draw a large amount of current when they start.

Frequent starting heats up the motor windings and can lead to failure.

By ensuring the pump runs for at least one minute each time it turns on, you drastically extend its life.

This is the "one-minute runtime" rule.

The Sizing Formula

The standard formula is simple:

Drawdown Needed = Pump Flow Rate (GPM) x 1 (minute)

So, if your submersible pump is rated at 15 GPM, you need a pressure tank system that provides 15 gallons of drawdown.

A Step-by-Step Example

Let's walk through a real-world scenario.

-

Determine Pump Flow Rate: You've identified your deep well submersible pump has a flow rate of 12 GPM.

-

Identify Pressure Settings: Your pressure switch is set to a standard 40/60 PSI.

-

Calculate Required Drawdown: You need a minimum of 12 gallons of drawdown (12 GPM x 1 minute).

-

Consult a Drawdown Chart: Now you look at a manufacturer's chart for their pressure tanks.

| Tank Model | Total Volume | Drawdown at 40/60 PSI |

|---|---|---|

| T-20 | 20 Gallons | 5.5 Gallons |

| T-32 | 32 Gallons | 8.7 Gallons |

| T-44 | 44 Gallons | 11.9 Gallons |

| T-60 | 60 Gallons | 16.2 Gallons |

In this case, the T-44 model provides 11.9 gallons of drawdown, which is very close to the required 12 gallons.

This would be a perfectly acceptable choice.

However, choosing the T-60 model, which provides 16.2 gallons of drawdown, would be even better.

It would make your pump run for longer but less frequently, further reducing wear and tear.

When in doubt, it is always safer to go up to the next size tank.

The small additional cost is cheap insurance for your expensive pump motor.

How Is Sizing Different for a Solar Pump System?

Are you planning an off-grid water system?

A solar setup has different rules.

Applying standard sizing methods could leave you without water when the sun isn't shining.

**When sizing a pressure tank for a solar pump, the goal shifts from just protecting the pump to storing energy as water.

A much larger tank is used to buffer against cloudy days and for nighttime use.**

With a solar water pump, your power source is variable.

You have abundant energy at noon but zero energy at night.

The sizing strategy must account for this.

Instead of just aiming for a one-minute pump runtime, you are now designing a "water battery."

The pressure tank's purpose is to store enough pressurized water to meet your needs during periods of low or no sun.

This means the tank will almost always be significantly larger than one used in a grid-tied system.

Sizing Based on Water Usage

The thought process changes completely.

-

Calculate Daily Water Needs: First, estimate how much water your household, farm, or livestock uses per day.

For example, a small homestead might require 300 gallons per day. -

Determine a Reserve: Decide how much of a reserve you want.

A common goal is to store enough for one full day of use without any sun.

So, you aim to store 300 gallons of usable water. -

Size the Tank System: Using a standard 40/60 PSI setting, a tank's drawdown is roughly 25-30% of its total volume.

To get 300 gallons of drawdown, you would need a total tank volume of about 1000-1200 gallons.

This is often achieved by connecting multiple large tanks together.

The Role of the Pump Type

The type of solar pump you use also influences the system design.

Different pumps are optimized for different tasks, which affects how you pair them with a tank.

-

Solar Screw Pump: This pump provides low flow but can push water from extreme depths (high head).

Because its flow rate is low, it runs for longer periods to fill a large storage tank.

It's perfect for keeping a large tank system full for domestic use in arid regions. -

Solar Plastic Impeller Pump: This is a high-flow workhorse.

It can fill a large tank very quickly during peak sun hours.

It is ideal for farm irrigation where large volumes of water are needed in a short time, with the tank providing pressure when the pump is off. -

Solar Stainless Steel Impeller Pump: This premium pump offers high flow and excellent durability in corrosive water.

For high-end off-grid homes or ranches, it can be paired with a large tank system to provide reliable, high-quality water pressure 24/7, regardless of water chemistry.

In all solar scenarios, the tank decouples water usage from water pumping.

You can use water anytime, even though the pump only runs when the sun is strong.

How Does Motor Efficiency Affect the System?

Does the pump's motor really matter for tank sizing?

It might seem disconnected.

But an inefficient motor wastes the very energy your tank is trying to save.

**A high-efficiency motor, like a BLDC model, is the heart of a modern pump system.

It reduces energy costs and works perfectly with a properly sized tank to create a highly optimized and durable water solution.**

The pressure tank's job is to reduce how often the pump's motor has to start.

The motor's job is to convert electrical energy into water pressure as efficiently as possible.

These two components work hand-in-hand.

An inefficient motor negates many of the benefits of a well-sized tank.

It wastes electricity every second it runs.

Conversely, a hyper-efficient motor amplifies the benefits of a good tank.

The BLDC Motor Advantage

Modern solar and booster pumps increasingly use Brushless DC (BLDC) permanent magnet motors.

These are a technological leap forward.

-

Extreme Efficiency: BLDC motors achieve efficiencies over 90%.

This means for every 100 watts of power from your solar panels or grid, over 90 watts are used to move water.

Older motors might only be 50-60% efficient. -

Less Power Required: Because they are so efficient, a BLDC-powered pump can do the same work with less energy.

This can reduce the number of solar panels needed by up to 30%, saving significant cost on the initial installation. -

Durability: The brushless design means there are no parts to wear out.

This, combined with the reduced starts from a properly sized pressure tank, leads to an exceptionally long service life with virtually no maintenance.

The Smart Controller's Role

The system is made complete by an intelligent controller.

This "brain" manages the power going to the highly efficient BLDC motor.

Controllers with MPPT (Maximum Power Point Tracking) technology squeeze every last watt of available power from the solar panels.

Furthermore, advanced AC/DC hybrid controllers offer the ultimate in reliability.

They can be connected to solar panels and a backup AC source (grid or generator) simultaneously.

The controller will always prioritize using free solar energy.

When the sun is strong, it powers the pump to fill the pressure tank.

If solar power fades and the tank pressure drops, the controller can automatically switch to the AC source to run the pump.

This ensures your large, well-sized tank stays full and you have uninterrupted water pressure, day or night, rain or shine.

This intelligent synergy between an efficient motor, a smart controller, and a large pressure tank is the key to a modern, resilient water system.

Conclusion

Sizing a pressure tank correctly is vital.

It protects your pump's motor, saves energy, and, in solar systems, ensures water is available 24/7 by storing it effectively.

Frequently Asked Questions

What happens if a pressure tank is too small?

A small tank causes rapid pump cycling.

This leads to motor overheating, premature failure, and higher energy consumption.

Is it okay to oversize a pressure tank?

Yes, oversizing is generally better than undersizing.

A larger tank will reduce pump cycles, extending the motor's life and improving energy efficiency.

What should the air pressure be in a water pressure tank?

The pre-charge air pressure should be set to 2 PSI below the pump's cut-in pressure setting.

This must be done when the tank is empty of water.

How long should a pressure tank last?

A good quality, well-maintained steel pressure tank can last 10-15 years or more.

Factors like water quality and proper pre-charge can affect its lifespan.

Can you put two pressure tanks together?

Yes.

Connecting two or more tanks in parallel is a common way to increase the system's total drawdown capacity without replacing the existing tank.

How do I know if my pressure tank is bad?

Signs of a failing tank include rapid pump cycling, constantly running pump, or water sputtering from faucets.

You can also check the air valve; if water comes out, the internal bladder has failed.

Does a variable speed pump need a pressure tank?

Variable speed pumps (VSDs) don't require a large pressure tank for cycling.

However, a small tank is still recommended to prevent short cycling from small leaks.