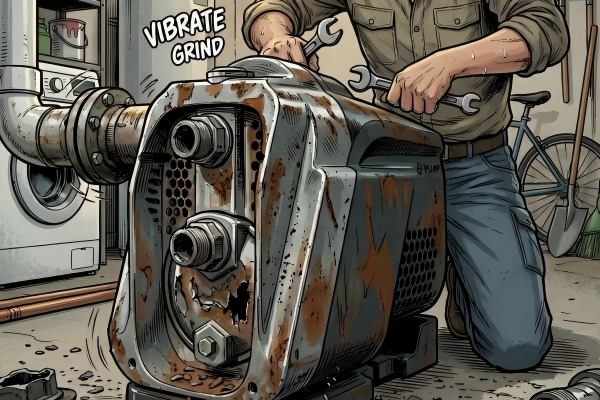

Your pump sounds like it is full of gravel.

It is noisy, vibrating, and its performance has plummeted.

This destructive sound is cavitation, and understanding it is the key to protecting your investment and ensuring a reliable water supply.

Cavitating a pump means the rapid formation and violent collapse of vapor bubbles inside the pump.

This happens when the liquid pressure drops below its vapor pressure.

These mini-explosions cause severe noise, vibration, and physical damage to the pump's internal components.

That horrible grinding noise is not from rocks.

It is the sound of your pump destroying itself from the inside.

Each tiny vapor bubble that collapses releases a shockwave of energy.

This energy is powerful enough to chip away at even the hardest metals over time.

Think of it as thousands of microscopic hammer blows hitting the pump's impeller or screw every second.

This process is a pump's worst enemy.

It is not a sign of normal wear and tear.

It is a symptom of a serious problem in your water system's design or operation.

Ignoring cavitation is like ignoring a loud knocking sound in your car's engine.

The problem will not fix itself.

It will only get worse, leading to a catastrophic and costly failure.

To stop this destruction, you must first understand why it is happening.

We will break down the science behind cavitation, explore its common causes, and show you how it affects different types of pumps.

This knowledge will empower you to diagnose your system, prevent damage, and ensure your pump operates safely and efficiently for years to come.

Part 1 | Understanding the Root Causes of Cavitation

You know cavitation is damaging your pump, but you are not sure why it is happening.

Without identifying the source of the problem, any fix is temporary, and the destructive process will continue.

The good news is that cavitation has specific, measurable causes that can be corrected.

The main causes of cavitation are insufficient Net Positive Suction Head (NPSH), a blocked or improperly sized suction line, high water temperature, or operating the pump too far from its Best Efficiency Point (BEP).

Essentially, anything that excessively lowers pressure at the pump's inlet.

Cavitation is a pressure problem.

It begins when the pressure of the water entering the pump drops too low.

Every liquid has a "vapor pressure," the pressure at which it will start to boil at a given temperature.

If the pressure inside the pump inlet drops below this point, the water spontaneously boils, forming tiny vapor bubbles.

These bubbles are then swept into the higher-pressure sections of the pump, where they instantly and violently collapse.

This entire process is dictated by a critical metric called Net Positive Suction Head, or NPSH.

The Central Role of NPSH

NPSH is the most important factor in preventing cavitation.

It is a measure of the total pressure available at the pump's suction inlet.

There are two sides to the NPSH equation:

- NPSHa (Available): This is the absolute pressure that your specific system provides at the pump inlet. It is determined by factors like the atmospheric pressure, the height of the water source relative to the pump, and the friction losses in the suction piping.

- NPSHr (Required): This is the minimum pressure the pump manufacturer specifies is needed at the inlet to prevent cavitation. It is an inherent characteristic of the pump's design.

To avoid cavitation, the rule is simple: NPSHa must always be greater than NPSHr.

A good rule of thumb is to have NPSHa be at least 10-15% higher than NPSHr to provide a safety margin.

Common System Flaws That Reduce NPSHa

Several common installation mistakes can starve a pump of pressure and induce cavitation.

- Excessive Suction Lift: The higher the pump is placed above the water source, the more it has to work against gravity, which drastically reduces the inlet pressure.

- Blocked Intake: A clogged strainer, foot valve, or a partially closed valve on the suction side acts like a choke, restricting flow and creating a major pressure drop.

- Improper Pipe Sizing: Using a suction pipe that is too narrow for the required flow rate causes high fluid velocity and significant friction losses, which craters the NPSHa.

| Pipe Diameter | Flow Rate | Velocity | Pressure Loss (per 100 ft) | Cavitation Risk |

|---|---|---|---|---|

| 1 inch | 10 GPM | 10.2 ft/s | ~23 PSI | Very High |

| 1.5 inch | 10 GPM | 4.5 ft/s | ~4 PSI | Moderate |

| 2 inch | 10 GPM | 2.6 ft/s | ~1 PSI | Low |

This table clearly shows that a small increase in pipe diameter can dramatically reduce pressure loss and lower the risk of cavitation.

Part 2 | How Cavitation Erodes Centrifugal Pumps

Your centrifugal pump is making a terrible noise, and you are worried its plastic or steel impellers are being eaten away.

You fear the pump's core is failing, leading to a complete loss of water pressure and an expensive replacement.

It is crucial to understand how cavitation specifically targets these pumps to appreciate the damage being done.

In centrifugal pumps, cavitation damage is focused on the impeller blades.

The bubble implosions act like a sandblaster, eroding the impeller material.

This pitting weakens the blades, alters their hydraulic profile, and drastically reduces efficiency and flow rate.

Centrifugal pumps work by using a spinning impeller to create a low-pressure zone at its center, or "eye."

This low pressure is what draws water into the pump.

Unfortunately, this design makes the eye of the impeller the most likely place for cavitation to begin.

When system conditions are wrong and the inlet pressure drops too low, vapor bubbles form in this low-pressure eye.

As the impeller spins, it flings these bubbles outward.

The further they travel along the impeller vane, the higher the pressure becomes.

This rapidly increasing pressure causes the bubbles to collapse violently against the surface of the impeller blade.

These implosions are incredibly powerful, creating localized pressure spikes that can exceed 100,000 PSI.

This is more than enough force to blast away microscopic pieces of the impeller material.

The Destructive Path on an Impeller

The damage is not random.

It follows a predictable pattern.

- Formation: Bubbles form at the eye of the impeller where pressure is lowest.

- Transport: The spinning impeller carries the bubbles along the vanes toward the outer edge.

- Collapse: As the bubbles enter the high-pressure region near the impeller's discharge, they implode against the vane surface.

- Erosion: Over millions of cycles, these implosions create a characteristic pitted, "spongy" appearance on the impeller, typically on the low-pressure side of the blade.

Material Matters: Plastic vs. Stainless Steel

The material of the impeller significantly affects how well it withstands cavitation.

- Plastic Impeller Pumps: These are economical and highly resistant to abrasion from fine sand. However, the engineered plastics used, while durable, are softer than metal. Sustained cavitation can erode them relatively quickly, leading to a rapid fall-off in performance. The damage often looks like the material has been melted or chewed away. They are excellent for high-flow, low-head applications but must be operated within their specified NPSH range to avoid damage.

- Stainless Steel Impeller Pumps: These are the premium choice for durability and corrosion resistance. SS304 stainless steel is much harder than plastic and can withstand the forces of cavitation for a longer period. However, it is not immune. Given enough time, even stainless steel will be pitted and destroyed. Because they are often used in more critical or high-value applications, preventing cavitation through proper system design is even more important.

For a distributor, this means advising customers is key.

A plastic impeller pump is a great value, but only if the customer's system provides adequate NPSH.

If the system is borderline, recommending a stainless steel model or, better yet, helping the customer fix their intake piping, is the responsible choice.

Part 3 | Cavitation's Unique Attack on Screw Pumps

Your deep well screw pump is running rough, and you suspect a problem.

You worry that its unique design might be vulnerable to cavitation in a way you do not understand.

This uncertainty can lead to a misdiagnosis, where you might blame sand wear when cavitation is the real enemy.

In a screw pump, cavitation does not erode a metal impeller.

Instead, it attacks the soft rubber stator that forms a seal against the stainless steel screw.

The bubble implosions tear and rip at the rubber, destroying the seal and causing a massive loss of pressure.

A screw pump, or progressing cavity pump, does not have an impeller.

It uses a helical steel rotor (the screw) turning inside a resilient rubber stator.

This action creates sealed cavities that move water, generating very high pressure (head).

The low-pressure zone in this pump is at the intake, just before the first sealed cavity is formed.

If the inlet pressure is too low, vapor bubbles will form in the water just as it enters the pump.

These bubbles are then trapped inside the first sealed cavity along with the water.

As the rotor turns, it compresses this cavity.

The rising pressure causes the vapor bubbles to implode violently.

But instead of striking a hard metal impeller, these shockwaves slam into the soft, flexible wall of the rubber stator.

The Mechanism of Stator Failure

This attack is relentless and leads to a specific type of failure.

The continuous, high-energy implosions do not just erode the rubber; they physically tear and rip chunks out of it.

This damage is most severe near the pump's intake section.

- Loss of Seal: The primary function of the stator is to form a tight seal with the rotor. When chunks of rubber are missing, this seal is compromised.

- Internal Recirculation: Water begins to leak backward from the high-pressure cavity to the low-pressure cavity.

- Drastic Pressure Drop: This internal leakage means the pump can no longer build pressure effectively. Even if the motor is spinning at full speed, the head and flow rate will drop dramatically. An operator might notice their tank is not filling up, even though the pump sounds like it is running.

Differentiating Cavitation from Sand Wear

It is critical for technicians and users to distinguish between damage from cavitation and damage from abrasive sand.

While both can ruin a stator, they leave different signatures.

- Sand Wear: This typically appears as smooth, even wear along the entire length of the stator. The sharp edges of the stator's profile will be rounded off.

- Cavitation Damage: This looks like chunks or pieces have been gouged out of the rubber. The damage is often concentrated in the first few inches of the stator on the suction side, while the rest of the stator might look relatively new.

Understanding this difference is vital for a correct diagnosis.

If a user replaces a "sand-worn" stator without addressing the low NPSH issue that actually caused the cavitation, the new stator will be destroyed just as quickly.

For a distributor in a region with deep wells, like Latin America, educating installers on this point is essential for preventing repeat failures and warranty claims.

Part 4 | How Motor and Controller Tech Can Signal Problems

You see your pump's performance dropping, but you assume it is just normal wear.

You might be ignoring clear warning signs from the system's electronics that a serious problem like cavitation is occurring.

This can lead to a catastrophic failure that could have been identified and prevented much earlier.

An intelligent motor and controller system can detect cavitation.

The controller's MPPT algorithm will register an abnormal drop in the motor's power draw (watts) as cavitation reduces the pumping load.

This electronic data is a key early warning sign of a severe hydraulic problem.

Modern solar pump systems are more than just a motor and a "wet end."

They are sophisticated electronic systems.

The core of this system is the high-efficiency BLDC permanent magnet motor and its intelligent MPPT (Maximum Power Point Tracking) controller.

This controller's main job is to optimize the power from the solar panels.

However, it also provides a powerful diagnostic window into the pump's operation.

The controller constantly monitors key parameters like motor speed (RPM), voltage, and, most importantly, the actual power being consumed (watts).

In a healthy system, there is a predictable relationship between the motor's speed and the power it draws.

To pump a certain amount of water to a certain height, the motor must do a specific amount of work, which requires a specific amount of power.

When cavitation begins, the pump is no longer pumping a solid column of water.

It is pumping a mix of water and water vapor.

This mixture is much less dense and easier to move than solid water.

As a result, the hydraulic load on the motor drops significantly.

Reading the Electronic Signs

The intelligent controller will detect this change instantly.

Even though the motor might still be spinning at a high RPM, the controller's display will show a power draw that is abnormally low for that speed.

- Normal Operation: At 3000 RPM, the motor might draw 750 watts to lift water from a 200-foot well.

- Cavitation Condition: The controller might still show 3000 RPM, but the power draw could drop to 400 watts.

This mismatch is a red flag.

The motor is spinning freely because it is not doing the work it is supposed to do.

The controller is essentially telling you: "I am sending power to the motor, but the motor is not meeting any resistance."

This points directly to a problem on the hydraulic side of the system, with severe cavitation being a primary suspect.

The Value of Advanced Diagnostics

This diagnostic capability is invaluable for remote pump installations.

An installer can check the controller and see the data.

If they see high RPMs combined with low wattage, they can immediately rule out an electrical or motor problem.

They can confidently tell the customer that the issue is hydraulic—likely a blocked well screen, a fallen water level increasing the suction lift, or another cause of low NPSH.

This feature, built into high-quality BLDC motor and controller systems, turns a mysterious performance drop into a diagnosable issue.

It saves time, prevents incorrect repairs, and helps protect the long-term health of the entire pump system.

Conclusion

Cavitation is the destructive formation and collapse of vapor bubbles inside a pump.

It is caused by low inlet pressure and will severely damage any pump type if not corrected.

Frequently Asked Questions

What does pump cavitation sound like?

Pump cavitation sounds like the pump is trying to move gravel or marbles.

It is a loud, low-frequency rumbling or cracking noise accompanied by heavy vibration.

Can a pump run dry without damage?

Most pumps cannot run dry without damage.

Water is used for cooling and lubrication.

Some advanced systems have run-dry protection built into the controller to shut the pump off.

What is the difference between cavitation and aeration?

Cavitation is the formation of vapor bubbles from the liquid itself due to low pressure.

Aeration is when external air is sucked into the pump, usually from a leak in the suction line.

How do you fix a cavitating pump?

Fixing cavitation involves increasing the pressure at the pump inlet.

This can mean cleaning a blocked filter, lowering the pump, or using a larger diameter suction pipe.

Can cavitation cause a pump to overheat?

Yes, indirectly.

While the motor load drops, the vibration and inefficient operation can lead to bearing failure and motor burnout over time if the problem is not addressed.

Does a VFD help with cavitation?

A Variable Frequency Drive (VFD) can help manage cavitation.

By slowing the pump's speed, you can reduce the NPSHr (required pressure), which may be enough to stop cavitation in some systems.

What is dead heading a pump?

Dead heading is operating a pump with the discharge valve completely closed.

This causes the water to recirculate and rapidly heat up, which can quickly lead to severe cavitation and failure.