Are you confused about how a Variable Frequency Drive (VFD) controls a motor?

It seems complex, but the core principle is a clever three-step power conversion process.

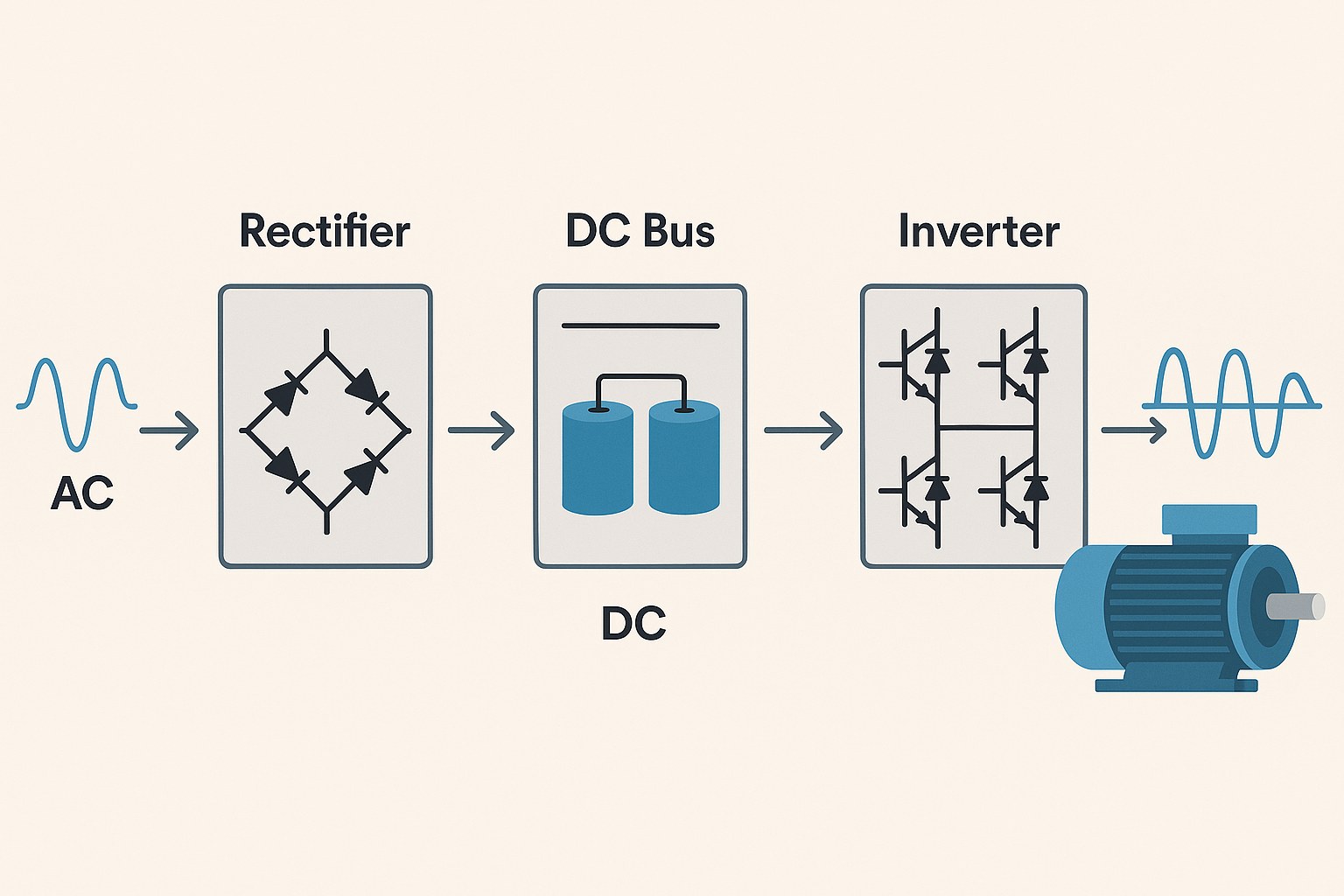

Yes, a VFD first converts AC power to DC. It uses an internal component called a rectifier to transform the incoming AC supply into DC voltage. This DC power is then smoothed out before an inverter converts it back into a precisely controlled, variable-frequency AC output for the motor.

This AC-to-DC-to-AC conversion is the secret behind a VFD's ability to precisely control motor speed, offering huge benefits in efficiency and performance.

It's a foundational technology that has revolutionized countless applications, from large industrial machinery to advanced residential water pumps.

Understanding this process unlocks a deeper appreciation for the intelligence and sophistication built into modern motor control systems.

Let's explore the key technological pillars that build upon this core principle to create a truly high-performance system.

Core Drive Technology and Performance

Is your pump system suffering from fluctuating water pressure and high energy bills?

This inefficiency is a common problem with traditional fixed-speed pumps.

A modern pump solves this by combining a Variable Frequency Drive (VFD) with a high-efficiency Permanent Magnet Synchronous Motor (PMSM). This pairing allows the pump to precisely match motor speed to water demand, ensuring constant, stable pressure while dramatically cutting energy consumption.

The synergy between the VFD and a high-efficiency motor is the cornerstone of modern intelligent pump systems.

This combination moves beyond the simple on/off functionality of older pumps, introducing a level of control that directly translates to better performance, lower operating costs, and enhanced durability.

It's not just about running the pump; it's about running it smartly and efficiently.

Let's break down the tangible benefits this core technology delivers.

The Power of VFD and PMSM Synergy

The heart of the system is the intelligent interplay between the VFD controller and a Permanent Magnet Synchronous Motor (PMSM).

The VFD acts as the brain, constantly monitoring system pressure.

The PMSM, known for its incredible efficiency and power density, acts as the muscle.

When water is used, the pressure drops slightly.

The VFD detects this drop instantly and signals the PMSM to increase its speed just enough to bring the pressure back to the setpoint.

Conversely, when water use decreases, the VFD slows the motor down.

This constant, automatic adjustment ensures the pump only uses the exact amount of energy needed at any given moment, eliminating the waste associated with fixed-speed pumps that always run at 100% power.

Achieving Near-Silent Operation

A significant advantage of this technology is its remarkably quiet performance.

Traditional pumps, especially when they start and stop abruptly, can be a major source of noise pollution in a home or commercial building.

The VFD-PMSM combination addresses this issue directly.

The VFD ensures the motor runs smoothly across a range of speeds, avoiding the harsh mechanical noises of on/off cycling.

Furthermore, high-efficiency PMSMs are inherently quieter than their asynchronous counterparts due to their design.

The result is an operational noise level often below 50 decibels, which is quieter than a normal conversation or the hum of a modern refrigerator.

This makes these pumps ideal for installation in noise-sensitive environments like residential homes, hospitals, and hotels.

The Critical Role of Soft Start and Soft Stop

Water hammer is a destructive force in plumbing systems.

It occurs when a fixed-speed pump starts or stops suddenly, causing a pressure surge that slams through the pipes.

This can lead to noisy vibrations, damaged joints, and even burst pipes over time.

A VFD completely eliminates this problem through its soft start and soft stop functionality.

| Function | Action | Primary Benefit |

|---|---|---|

| Soft Start | The VFD gradually ramps the motor's speed up from zero to the required operational speed. | Prevents the sudden inrush of current and the hydraulic shock (water hammer) associated with abrupt starts. |

| Soft Stop | The VFD smoothly decelerates the motor to a complete stop when demand ceases. | Eliminates the pressure surge that occurs when flow is stopped suddenly, protecting pipes and fixtures. |

This gentle acceleration and deceleration significantly reduce mechanical stress on the motor, bearings, and pump impeller.

It also protects the entire plumbing network from damaging pressure shocks.

This feature is not a luxury; it's a fundamental aspect of system longevity and reliability, saving on costly repairs and extending the life of all connected components.

Excellence in Mechanical and Material Engineering

Are you worried that a new pump's advanced electronics are hiding low-quality mechanical parts?

This is a valid concern, as a system is only as strong as its weakest link.

True excellence is achieved when sophisticated electronic controls are paired with robust mechanical engineering. This means using premium materials like AISI304 stainless steel impellers, high-precision bearings, and advanced motor components to ensure the entire unit is built for durability and a long service life.

The long-term reliability of any advanced pump system depends heavily on the quality of its physical components.

While the VFD provides the intelligence, the motor and pump end do the hard work.

Sourcing and integrating superior materials is a non-negotiable aspect of designing a product that can withstand years of continuous operation.

This commitment to mechanical quality ensures the pump's performance doesn't degrade over time and provides peace of mind that the investment is a lasting one.

Let's delve into the specific material and engineering choices that define a top-tier VFD pump.

Designing a Superior Motor Stator

The stator is a stationary part of the motor that creates a rotating magnetic field.

Its quality directly impacts the motor's efficiency, heat generation, and lifespan.

A high-performance stator is engineered with several key features.

It often uses high-grade silicon steel, which has excellent magnetic properties and reduces energy loss in the motor's core.

This directly translates to higher efficiency, meaning more of the electrical energy is converted into mechanical work and less is wasted as heat.

Superior thermal management is indicated by a low temperature rise (often specified as ≤50K), which means the motor runs cooler, a critical factor for longevity.

Finally, using high-temperature-rated insulation wire (such as Class F) and incorporating dual insulation provides robust protection against electrical faults and thermal breakdown, ensuring safe and reliable operation even under demanding conditions.

The Importance of Advanced Magnets and Bearings

The rotor is the rotating component of the motor.

In a high-efficiency PMSM, the rotor contains powerful permanent magnets.

The quality of these magnets is crucial.

Advanced ferrite or rare-earth magnets that can withstand high temperatures (e.g., up to 150°C) without losing their magnetic strength are essential for sustained performance.

This ensures the motor maintains its torque and efficiency throughout its operational life.

Equally important are the bearings, which support the rotor and allow it to spin freely.

Using premium, high-precision bearings from reputable manufacturers is a hallmark of a quality product.

Compared to standard alternatives, these bearings offer:

- Higher Precision: Reduced wobble and vibration for smoother operation.

- Quieter Performance: Lower friction contributes to the system's overall low noise level.

- Longer Lifespan: Superior materials and manufacturing tolerances mean they last significantly longer, reducing maintenance needs.

The Unseen Advantage of Premium Hydraulic Components

The "wet end" of the pump, which contains the impeller and housing, is what actually moves the water.

The material choice here is critical for both performance and safety, especially with drinking water.

The impeller is the heart of the pump, a rotating component with vanes that imparts energy to the water.

Using a material like AISI304 stainless steel is a superior choice.

This grade of stainless steel is renowned for its excellent corrosion resistance, ensuring it won't rust or degrade over time, even with varying water quality.

It's also strong and durable, able to withstand the high rotational speeds and pressures involved.

This material choice ensures the water remains clean and untainted while guaranteeing the pump's hydraulic performance remains consistent for years.

Uncompromising Electronic Reliability and Sealing

Are your pump installations failing prematurely due to moisture, dust, or condensation?

This is a common point of failure for electronics operating in damp or harsh environments.

The ultimate solution for electronic durability is to completely seal the main controller board in a protective compound. This process, known as potting, creates a 100% waterproof and dustproof barrier, achieving a high IP (Ingress Protection) rating like IP67 and extending the controller's life by years.

A pump's VFD controller is a sophisticated piece of electronics, packed with microprocessors, sensors, and power components.

Unfortunately, it often has to operate in environments that are hostile to electronics, such as damp basements, humid utility rooms, or dusty outdoor enclosures.

Protecting this electronic brain from the elements is arguably the most critical factor in ensuring the long-term, trouble-free operation of the entire system.

Let's examine how advanced sealing technology provides a fortress for these sensitive components.

Understanding PCB Potting

Printed Circuit Board (PCB) potting is a process where the entire electronic assembly is encased in a solid, non-conductive compound, typically an epoxy or polyurethane resin.

This goes far beyond simple conformal coatings which only apply a thin layer of protection.

Potting creates a solid block that completely encapsulates every component, solder joint, and trace on the board.

This encapsulation process provides several crucial advantages.

It creates a perfect, impenetrable seal against any external contaminants.

It also provides excellent resistance to shock and vibration, as all components are held rigidly in place.

This makes the electronics incredibly robust and able to withstand the minor vibrations inherent in any motor-driven system.

The Meaning and Value of an IP67 Rating

The IP rating system is an international standard that classifies the degree of protection provided against the intrusion of solid objects (like dust) and liquids (like water).

An IP67 rating signifies the highest level of protection against dust and a very high level of protection against water.

Let's break down what the numbers mean:

| Digit | Meaning (First Digit: Solids) | Meaning (Second Digit: Liquids) |

|---|---|---|

| 6 | Dust Tight: No ingress of dust; complete protection against contact. This is the highest rating for solid protection. | |

| 7 | Immersion Protection: Ingress of water in harmful quantity shall not be possible when the enclosure is immersed in water under defined conditions of pressure and time (up to 1 meter of submersion for 30 minutes). |

Achieving an IP67 rating for the core electronics through potting means the controller is essentially invulnerable to common environmental threats.

It can withstand splashes, high humidity, condensation, and even temporary submersion without damage.

This level of protection is claimed to prevent over 95% of failures related to moisture, dramatically increasing the system's reliability in real-world conditions.

Long-Term Benefits of Enhanced Sealing

The decision to invest in advanced sealing like PCB potting has significant long-term implications.

It directly translates to a lower total cost of ownership.

By preventing the most common causes of electronic failure, it drastically reduces the likelihood of needing costly service calls and controller replacements.

This protection is projected to extend the lifespan of the electronic controller by an additional 3 to 5 years compared to unsealed or minimally coated boards.

For an importer, distributor, or installer, this means fewer warranty claims, higher customer satisfaction, and a stronger reputation for providing reliable, high-quality products.

For the end-user, it means years of dependable, worry-free operation from their water pressure boosting system.

The "14-Shield": A Comprehensive Suite of Protection Functions

Do you fear that a power surge or a dry well could instantly destroy your expensive pump?

These operational hazards can cause catastrophic failure in unprotected systems.

A truly intelligent pump incorporates a comprehensive suite of active protection functions. This multi-layered "shield" constantly monitors electrical, thermal, and system parameters, automatically taking action to prevent damage from issues like dry running, voltage spikes, overheating, and more.

The true intelligence of a modern VFD pump lies not just in its ability to control pressure, but also in its capacity for self-preservation.

A sophisticated control system is equipped with an array of sensors that act as a nervous system, constantly monitoring the pump's health and its operating environment.

When a potentially damaging condition is detected, the controller's software reacts instantly to protect the hardware.

This active protection suite is what elevates a pump from a simple machine to a durable, resilient appliance.

Safeguarding Against Electrical and Thermal Threats

The VFD controller is the first line of defense against unstable power grids and thermal stress.

It continuously monitors incoming power and internal temperatures to prevent damage.

Key protections in this category include:

- Input Voltage Protection: The system will shut down safely if the incoming voltage is too high or too low, protecting the electronics from being damaged by brownouts or power surges.

- Overcurrent and Stall Protection: If the motor draws too much current, perhaps due to a jam or a blockage (a stall condition), the VFD will instantly cut power to prevent the motor windings from burning out.

- Overheating Protection: Multiple sensors monitor the temperature of the drive electronics and the motor itself. If temperatures exceed safe limits, the system will shut down to cool off, preventing permanent damage.

- Phase Loss Protection: In three-phase systems, this ensures the pump stops if one of the power phases is lost, which would otherwise quickly destroy the motor.

Intelligent System and Sensor Protections

Beyond electrical safety, the system protects itself from hydraulic and environmental issues.

The most critical of these is dry run protection.

Running a pump without water will quickly destroy its seals and internal components due to friction and overheating.

An intelligent system employs a multi-stage recovery algorithm to handle this.

If it detects a water shortage, it will stop and enter a "sleep" mode.

It then periodically attempts to restart for a short period to see if the water supply has returned.

This "probe-and-wait" strategy prevents damage while automatically restoring operation once water is available again, without requiring manual intervention.

Other essential system protections include:

- Antifreeze Protection: In cold climates, the pump can automatically run for brief periods if the water temperature nears freezing, preventing ice from forming and cracking the pump housing.

- Pipeline Leak Warning: The system can detect a small, continuous drop in pressure that indicates a leak in the plumbing, alerting the user to a potential problem.

- Sensor Failure Warnings: The pump continuously self-diagnoses its own sensors. If a pressure or temperature sensor fails, it will provide a specific error code, making troubleshooting fast and accurate.

Intuitive User Interface and Real-Time Monitoring

Do complex controls and confusing displays make you hesitant to install advanced equipment?

Technology should simplify, not complicate.

A well-designed VFD pump balances its internal complexity with a simple, user-friendly interface. It features intuitive controls for basic operations like setting pressure, while also providing easy access to detailed, real-time data for advanced monitoring and diagnostics.

All the advanced technology within a VFD pump is of little use if it cannot be easily controlled and understood by the user or installer.

The goal of a great interface is to make the powerful features accessible.

This involves a thoughtful combination of straightforward physical buttons, clear visual indicators, and a digital display that can present a wealth of information without being overwhelming.

This user-centric design approach ensures that anyone can operate the pump effectively and gain valuable insight into its performance.

Simplicity in Operation

For day-to-day use, the interface should be as simple as possible.

The most common tasks need to be intuitive.

This is typically achieved with a few dedicated buttons:

- Power Button: A simple press to turn the pump on or off.

- UP/DOWN Buttons: For easily increasing or decreasing the target water pressure. The digital display provides immediate feedback on the set value.

- Reset Function: Often integrated into the power button (e.g., a long press) to restore the pump to its factory default settings if needed.

This minimalist approach ensures that the primary function—setting and maintaining water pressure—is foolproof.

Deep Dive into Real-Time Data

For installers, technicians, or curious homeowners, a quality VFD pump offers the ability to see exactly what's happening under the hood.

A long press of a specific button can cycle the digital display through a series of key operating parameters.

This provides an invaluable, real-time diagnostic tool.

| Display Code (Example) | Parameter Shown | Why It's Useful |

|---|---|---|

A.xx |

Water Temperature (°C or °F) | Monitors for high temperatures; useful for solar hot water circulation systems. |

P.xxx |

Real-time Power (Watts) | Shows exactly how much energy the pump is consuming, demonstrating its efficiency. |

xxxx |

Motor Speed (RPM) | Confirms the VFD is correctly adjusting the motor speed based on demand. |

U.xxx |

Input Voltage (Volts) | Helps diagnose issues related to the power supply or grid instability. |

t.xx |

PCB Temperature (°C or °F) | Monitors the health of a key electronic component, ensuring it's operating within safe limits. |

This live data stream allows for quick system checks and helps pinpoint the source of any potential issues without needing specialized diagnostic equipment.

At-a-Glance Status Indicators

In addition to the digital display, a series of LED indicator lights provide immediate visual feedback on the pump's current status.

Each light is dedicated to a specific function or fault, allowing anyone to understand the pump's state at a glance.

Common indicators include:

- Constant Pressure: A light that confirms the pump is running normally and maintaining the set pressure.

- Water Shortage: A prominent warning light that indicates the pump has stopped due to a lack of water.

- Fault Indicator: A general alarm light that signals an electrical or system fault, often used in conjunction with an error code on the digital display.

- Power Level: Some interfaces include a gauge-like series of LEDs that show the current power output or motor speed, similar to a tachometer in a car.

This combination of a simple digital display and clear LED indicators makes the system both easy to operate and transparent in its performance.

Conclusion

In essence, a VFD intelligently converts AC to DC and back to variable AC.

This core function, when combined with robust mechanics and smart protections, creates highly efficient and reliable modern pumps.

FAQs

What is the main function of a VFD?

A VFD controls an AC motor's speed and torque. It does this by varying the frequency and voltage of the power supplied to the motor.

Does a VFD save energy?

Yes, significantly. By matching motor speed to the actual load demand, a VFD can reduce a pump's energy consumption by up to 50% or more.

Can a VFD run a 3 phase motor on single phase power?

Yes, many modern VFDs are designed to accept a single-phase input and produce a three-phase output, allowing 3-phase motors to be used on residential power supplies.

What is the difference between VFD and inverter?

The term "inverter" specifically refers to the final stage within a VFD that converts DC back to AC. A VFD is the complete unit, including the rectifier, DC bus, and inverter.

How does a VFD protect a motor?

A VFD provides comprehensive protection against overcurrent, overheating, voltage fluctuations, phase loss, and running dry. This extends the motor's operational lifespan.

What is PWM in VFD?

PWM (Pulse Width Modulation) is the technique the VFD's inverter uses. It switches the DC voltage on and off very rapidly to create a simulated AC sine wave of the desired frequency.

Do all VFDs have a DC bus?

Yes, the DC bus is a critical intermediate stage in every VFD. It uses capacitors to smooth the rectified DC voltage before it goes to the inverter stage.

Does a VFD change the horsepower of a motor?

No, a VFD does not change a motor's rated horsepower. It controls how that horsepower is used by adjusting the motor's speed and torque to match the load.