Tired of weak showers and trickling taps?

Low water pressure can disrupt your daily routines.

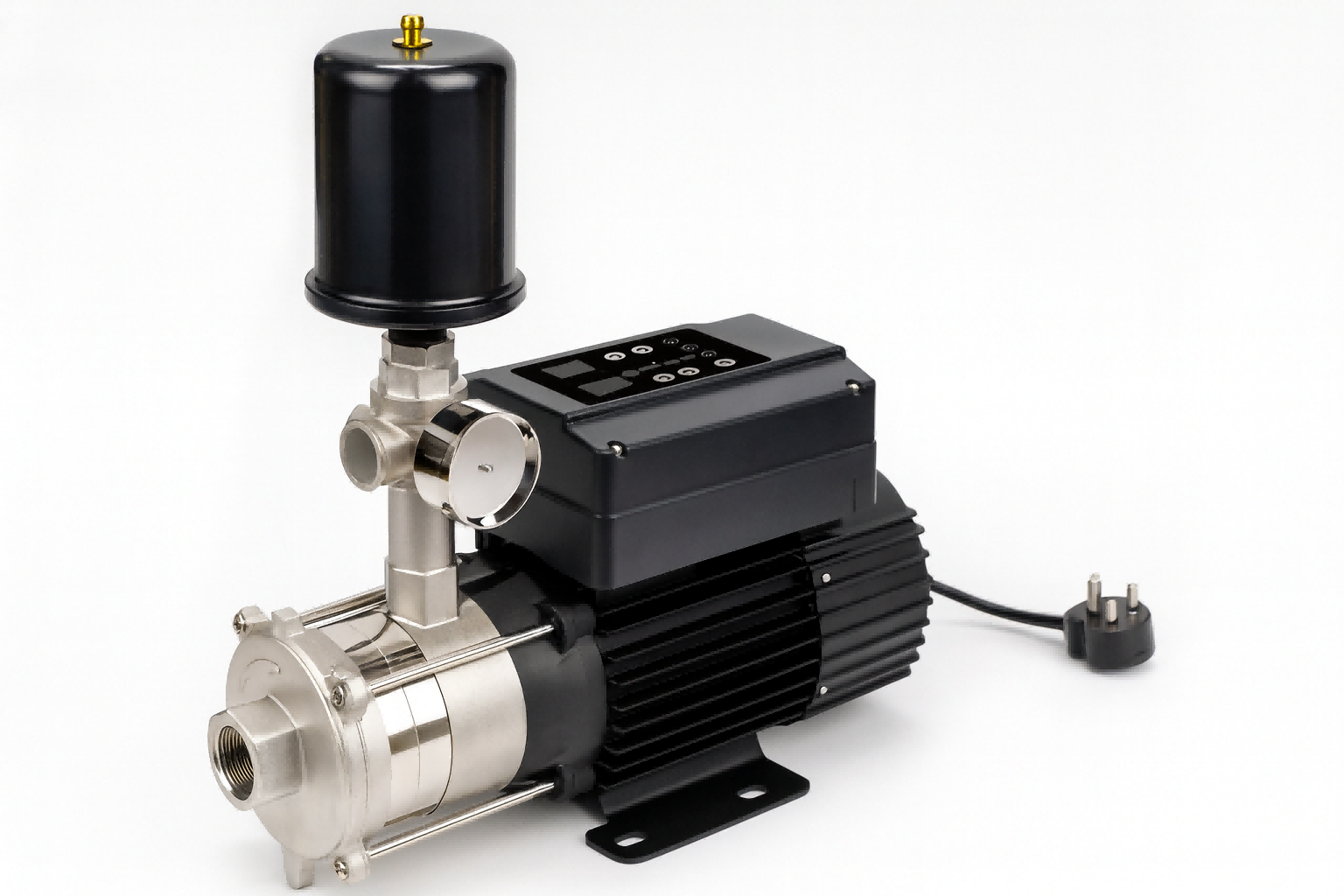

An automatic booster pump intelligently solves this by ensuring strong, consistent water flow throughout your property.

An automatic water pressure pump works by using a sensor to detect a drop in pressure, like when a tap is opened.

This sensor signals the motor to spin an impeller, which draws water in and powerfully pushes it out, instantly increasing pressure and flow until the tap is closed.

Understanding how these pumps operate is key to selecting the right system for your needs.

These devices are more than just motors; they are sophisticated systems designed to provide on-demand pressure, enhance efficiency, and protect your plumbing.

Let's explore the mechanics, benefits, and key technologies that make these pumps an essential component for modern homes and commercial buildings.

Why would I need to install a water pressure pump?

Experiencing slow-running taps or a shower that lacks force?

This is a classic sign of low water pressure in your plumbing system.

A booster pump is the definitive solution, designed to elevate your water flow to an ideal, powerful rate.

You need a water pressure pump if your home experiences consistently weak water flow.

This can be due to low municipal supply pressure, being on an upper floor, or having a rainwater harvesting system.

A pump ensures strong pressure for showers, appliances, and taps.

Low water pressure is more than a minor annoyance.

It can impact the efficiency of washing machines and dishwashers, make gardening with a hose difficult, and turn a simple shower into a frustrating experience.

In multi-story buildings, gravity naturally reduces pressure on higher floors, often making a booster pump a necessity rather than a luxury.

Similarly, systems that rely on rainwater harvesting or well water typically require a pump to deliver water at a usable pressure throughout the property.

An automatic booster pump not only solves these issues but does so intelligently, running only when needed to provide a powerful and consistent flow across all outlets.

Identifying Low Water Pressure

You can diagnose low water pressure without special tools.

The simplest method is the "one-liter jug test."

- Take an empty one-liter bottle or measuring jug.

- Turn a tap on fully and time how long it takes to fill the container.

- Record the time.

An ideal flow rate is between 10 and 15 liters per minute.

This means it should take between 4 and 6 seconds to fill your one-liter jug.

If it takes longer than six seconds, your water flow rate is low, indicating a pressure problem that a booster pump can fix.

Common Causes of Low Water Pressure

Several factors can lead to insufficient water pressure.

Understanding the root cause helps in choosing the most effective solution.

- Municipal Supply Issues: The pressure delivered by your local water authority might be low, especially if you live in a high-demand area or far from the water tower.

- Pipework Problems: Older homes may have corroded or clogged pipes that restrict water flow.

- Shared Pipelines: In apartment buildings or dense neighborhoods, pressure can drop when multiple households use water simultaneously.

- Home Elevation: If your home is situated on a hill or is a multi-story building, pressure naturally decreases as water travels upward.

A whole-house, inline mains booster pump is often the best solution to counteract these issues comprehensively.

How does a water pressure pump work?

Frustrated by how traditional pumps can cause pressure fluctuations?

Older systems often struggle to maintain a perfectly stable flow.

Modern automatic pumps use advanced technology to deliver consistent pressure, adapting instantly to your water usage.

An automatic pump uses a pressure or flow sensor to detect when a tap opens.

This activates a motor, which spins an impeller to draw water in and push it out at a higher pressure.

Advanced models use a Variable Frequency Drive (VFD) to precisely control motor speed for constant pressure.

At the heart of a modern automatic water pressure pump lies a sophisticated control and drive system.

Unlike basic pumps that simply switch on and off, advanced systems utilize intelligent technology for superior performance, efficiency, and longevity.

The Core Components and Their Synergy

Every water pressure pump contains four essential components, but in high-end systems, they work together with unparalleled precision.

- Motor: The powerhouse of the pump. Advanced systems use a Permanent Magnet Synchronous Motor (PMSM). These motors are significantly more energy-efficient and quieter than traditional asynchronous motors.

- Impeller: A rotating device with vanes that forcefully pushes water from the inlet to the outlet. The design and material, often AISI304 Stainless Steel, are crucial for durability and hydraulic efficiency.

- Inlet and Outlet: The ports through which water enters and exits the pump.

- Control System: This is the brain. In modern pumps, this consists of a Variable Frequency Drive (VFD) controller paired with precise sensors.

The VFD and PMSM Advantage

The combination of a VFD and a PMSM is what sets premium booster pumps apart.

- Constant Pressure: The VFD acts as a smart throttle for the PMSM motor. When you open a tap slightly, the VFD runs the motor at a low speed. If you open more taps, the VFD instantly increases the motor's speed (RPM) to maintain the exact same water pressure. This eliminates the annoying pressure fluctuations common with older pumps.

- Soft Start & Soft Stop: Instead of jolting to full power, the VFD gently ramps the motor up to speed and then back down. This crucial function drastically reduces mechanical stress on the pump and prevents "water hammer"—a damaging hydraulic shockwave in your pipes.

- Energy Efficiency: A conventional pump always runs at 100% power, wasting electricity. A VFD-controlled pump only uses the exact amount of energy needed for the current water demand, leading to energy savings of up to 50% or more.

- Ultra-Quiet Operation: The smooth, controlled operation of the PMSM motor, guided by the VFD, results in incredibly quiet performance, often below 50dB—quieter than a library.

| Feature | Traditional Pump | Modern VFD Pump |

|---|---|---|

| Pressure Control | Fluctuates (On/Off Cycle) | Perfectly Constant |

| Motor Speed | Fixed (Full Speed Only) | Variable (Adapts to Demand) |

| Energy Usage | High and Inefficient | Optimized and Low |

| Noise Level | Loud and Noticeable | Ultra-Quiet (≤50dB) |

| Component Stress | High (Sudden Starts/Stops) | Low (Soft Start/Stop) |

This intelligent approach not only provides a superior user experience but also extends the lifespan of the pump and protects the entire plumbing system.

What is a water pressure pump ideal for?

Thinking a booster pump is only for fixing weak showers?

While that's a key benefit, their applications are far broader.

These versatile pumps are essential for optimizing a wide range of water systems in both residential and light commercial settings.

A water pressure pump is ideal for boosting indoor water pressure to showers, toilets, and washing machines.

It is also essential for rainwater harvesting systems to make the collected water usable, and for powering automatic garden irrigation and sprinkler systems effectively.

The primary function of a water pressure pump is to increase water force and flow, making it a problem-solver for numerous applications where standard mains pressure falls short.

Key Applications

An automatic booster pump can be deployed in several key scenarios to great effect:

- Whole-House Pressure Boosting: For homes plagued by generally low water pressure, an inline pump installed on the mains supply can elevate the pressure for every tap, shower, and appliance. This ensures a consistent and powerful flow throughout the entire property.

- Rainwater Harvesting: Collected rainwater has no natural pressure. A pump is essential to draw water from the storage tank and deliver it at a high enough pressure for use in toilets, washing machines, and garden irrigation.

- Garden and Landscape Irrigation: Automatic sprinkler systems and drip irrigation require a minimum pressure to operate correctly. A booster pump ensures that all sprinklers pop up fully and distribute water evenly across the entire designated area.

- Boosting for Specific Appliances: In some cases, only certain appliances like an instantaneous water heater or a high-performance shower might require higher pressure. A dedicated pump can be installed to serve just that single application.

- Light Commercial Use: Small office buildings, cafes, or workshops can benefit from a booster pump to ensure adequate water pressure for restrooms, kitchens, and cleaning tasks, especially during peak usage hours.

- Hot Water Circulation: Advanced pump models capable of handling high temperatures (up to 75°C) are perfect for circulating hot water from solar heating systems, ensuring hot water is readily available at the tap.

By providing reliable, on-demand pressure, these pumps enhance comfort, improve appliance performance, and enable the use of alternative water sources.

How can I tell if there’s a problem with my water pressure pump?

Is your pump suddenly making strange noises or has your water pressure dropped again?

These are clear indicators of a potential issue.

Ignoring these warning signs can lead to more significant damage and costly repairs down the line.

You can tell there's a problem if you have no water, low pressure despite the pump, or if the pump won't start or stop.

Other signs include unusual noises like squeaking or grinding, vibrations, or visible water leaks from the pump housing or connections.

A properly functioning automatic water pump should operate quietly and reliably in the background.

When it starts to show symptoms, a methodical approach to troubleshooting can often identify the cause quickly.

Modern pumps with intelligent controllers often provide error codes on their display, which significantly simplifies diagnostics.

Common Problems and Diagnostic Steps

If you suspect an issue, start with these simple checks before calling a professional.

-

Check the Power Supply:

Is the pump receiving power?

Check the circuit breaker and ensure all electrical connections are secure.

Many smart pumps have a power indicator light to confirm they are energized. -

Inspect Shutoff Valves:

Valves can sometimes be accidentally partially closed, restricting water flow.

Trace the pipework from your water meter to the pump and ensure all valves, especially the main shutoff valve, are fully open. -

Pump Won't Start or Won't Stop Running:

- Won't Start: If power is on but the pump is silent, it could be a faulty pressure switch or a more serious issue within the electronic controller. In smart pumps, the display might show a "water shortage" or "dry run" error if the water supply is cut off.

- Won't Stop: This is a classic sign of a leak somewhere in your plumbing system. The pump detects a continuous pressure drop and keeps running to compensate. It can also indicate a failed pressure sensor.

Advanced System Protections and Warnings

Modern VFD pumps are equipped with extensive self-diagnostic capabilities.

Their control panels often display specific warnings that pinpoint the exact problem.

| Issue | Potential Cause | Smart Pump Indication |

|---|---|---|

| Excessive Noise/Vibration | Worn bearings or debris in the impeller. | No specific code, but requires immediate attention. |

| Leaking Pump | Worn seals or cracked pipework. | Visual inspection is key. A leak can trigger a "Pipeline Leak Warning." |

| Pump Cycles On/Off Rapidly | Small leak or problem with the pressure tank. | May show a "Pipeline Leak Warning" on the display. |

| Motor Overheating | Insufficient cooling, overload, or internal fault. | Display may show "Overheating Protection" or PCB/Water temperature readings. |

| No Water (Pump Running) | Water supply is off, or the pump has lost its prime. | Display will show "Water Shortage" or "Dry Run Protection" and may enter a self-priming recovery mode. |

These intelligent protections not only make troubleshooting easier but also actively safeguard the pump from catastrophic failure, for example, by shutting down automatically during a dry-run event to prevent the motor from burning out.

What are the pros and cons of an automatic pump controller?

Considering an automatic pump but weighing its value against simpler systems?

The advanced control offers significant benefits but also comes with different considerations.

Understanding both sides helps you make an informed investment in your water pressure system.

The pros of an automatic controller include constant pressure, energy savings, and crucial pump protections like dry-run prevention.

The main cons are a higher initial cost compared to manual systems and the electronic components requiring proper protection from moisture.

An automatic pump controller is the intelligent brain that transforms a basic pump into a smart, efficient appliance.

It consolidates the functions of multiple traditional components—like a pressure switch, pressure tank, and check valve—into a single, compact unit.

This integration brings a host of advantages but also introduces factors to consider.

Advantages of Automatic Control

Modern controllers, especially those with VFD technology, offer a compelling list of benefits that are highly valued by property owners and system installers.

- Superior Performance: The ability to maintain a perfectly constant flow and pressure provides an exceptional user experience, eliminating annoying fluctuations in the shower or at the tap.

- Unmatched Pump Protection: This is perhaps the most critical advantage. Automatic controllers have built-in safeguards that are simply absent in older systems. These include:

- Dry-Run Protection: Automatically shuts the pump off if the water supply runs out, preventing motor burnout.

- Overheating Protection: Monitors motor and electronics temperature and shuts down to prevent damage.

- Voltage Protection: Guards against damage from grid power that is too high or too low.

- Antifreeze Protection: Can cycle the pump periodically in freezing conditions to prevent ice damage.

- Enhanced Efficiency: By running the motor only at the speed required, VFD controllers significantly reduce electricity consumption, leading to lower utility bills over the pump's lifetime.

- System Longevity: Features like soft start/stop reduce mechanical wear on the motor and bearings. By minimizing on/off cycles, they also reduce stress on the entire plumbing system.

- Simplified Installation: An integrated controller eliminates the need to plumb and wire multiple separate components, making installation quicker and less complex.

Considerations and Potential Disadvantages

While highly beneficial, it's important to be aware of the following points:

- Higher Initial Cost: The advanced technology in a smart controller means the initial purchase price is higher than that of a traditional pump with a simple pressure switch. However, this is often offset by long-term energy savings and reduced maintenance costs.

- Electronic Susceptibility: Like any electronic device, the controller's circuit board is vulnerable to moisture. It is crucial to choose a model with a high IP (Ingress Protection) rating. Premium pumps feature fully sealed or "potted" electronics (rated at IP67), making them completely waterproof and impervious to dust and condensation.

- Installation Expertise: While plumbing is simpler, connecting the electrical components may require a qualified electrician, unless it's a "plug and play" model. Retrofitting into very old plumbing systems may also present challenges.

For most users, the significant advantages in performance, protection, and efficiency far outweigh the higher initial investment.

Conclusion

An automatic water pressure pump intelligently manages your water supply, providing strong, consistent flow on demand while offering superior efficiency and crucial protection for your entire system.

FAQs

What is the difference between a 30/50 and a 40/60 pressure switch?

These numbers represent the cut-in and cut-out pressures in PSI. A 40/60 switch provides a higher overall pressure, which is better for multi-story homes.

How do I know if my pump is dry-running?

A pump is dry-running if the motor is on but no water is flowing through it. Modern automatic pumps detect this and shut down to prevent damage.

How do you prime a water pressure pump?

Priming involves filling the pump housing and suction line with water before starting it, which allows the impeller to create suction and draw water from the source.

Can a booster pump be too powerful?

Yes, a pump that is too powerful can create excessive pressure, potentially damaging pipes, fittings, and appliances. It is essential to choose a pump correctly sized for your system.

How long should a water pressure pump last?

A quality water pressure pump should last 8 to 15 years. Longevity is greatly increased by features like soft start and comprehensive electronic protections.

Does a booster pump use a lot of electricity?

Traditional pumps can be energy-intensive. However, modern pumps with VFD controllers are highly efficient, using up to 50% less electricity by matching motor speed to water demand.

Can I install a water pressure pump myself?

While some homeowners can handle the plumbing, the electrical work should be performed by a qualified electrician to ensure safety and proper operation.

Why does my pump turn on and off frequently?

This issue, known as cycling, is often caused by a small leak in your plumbing or a problem with the system's pressure tank.