Your pump motor is humming, but you're not sure if water is moving.

This uncertainty can lead to wasted energy and severe pump damage if left unchecked.

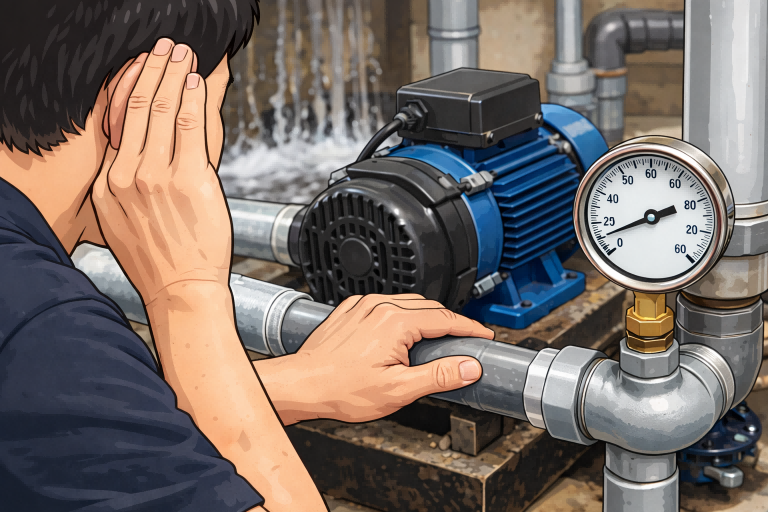

To check if a water pump is circulating, listen for the sound of flowing water, feel for vibrations and a cool outlet pipe, and check for a stable, positive reading on your pressure gauge.

Confirming circulation is the first and most critical step in diagnosing any pumping system.

A pump that runs without moving water—a condition known as running dry or dead-heading—can destroy itself in minutes.

The water it's supposed to move also acts as a coolant and lubricant for its internal components.

Without this flow, friction generates intense heat, which can melt plastic impellers, burn out seals, or cause the motor to overheat and fail.

Fortunately, you don't need to be a master technician to perform a few simple, non-invasive checks.

These initial steps can quickly tell you whether your pump is doing its job or just making noise, helping you prevent a minor issue from becoming a catastrophic failure.

Initial Sensory Checks: The First Line of Diagnosis

You suspect a problem but hesitate to start taking things apart.

A wrong move could complicate the issue.

Let your senses guide you to the first critical clues.

To perform a sensory check, listen for the distinct sound of water moving versus a hollow hum.

Feel the pump and pipes for vibration and temperature; a hot pump casing or a warm outlet pipe indicates a lack of cooling water flow.

Before you reach for a single tool, you can gather a significant amount of information just by paying close attention to the system.

A healthy pump has a specific sensory profile—a unique combination of sounds, vibrations, and temperatures.

When circulation stops, this profile changes dramatically.

Learning to recognize these changes is the quickest and most efficient way to diagnose a problem at its earliest stage.

These fundamental checks work on any pump, from a high-flow centrifugal model irrigating a farm to a high-head screw pump supplying a home from a deep well.

They are your first and most powerful diagnostic tool.

Auditory Clues: What Does a Healthy Pump Sound Like?

Your ears can often detect a problem before any other symptom becomes obvious.

A properly circulating pump has a consistent, smooth sound signature.

-

Normal Sounds: A centrifugal pump, like a solar plastic impeller pump or a solar stainless steel impeller pump, should produce a steady whirring or rushing noise. This is the sound of the motor combined with the sound of a large volume of water moving smoothly through the casing and pipes. A positive displacement pump, such as a solar screw pump, will have a more mechanical, lower-pitched sound as the screw rotor turns within the rubber stator. In both cases, the sound of water movement should be present.

-

Warning Sounds: If the pump is making a high-pitched humming or whining noise without the accompanying sound of water, it's likely airlocked or running dry. A loud rattling or grinding sound, often described as "pumping rocks," is a sign of cavitation. Cavitation occurs when air bubbles form and collapse violently inside the pump, and it can rapidly destroy an impeller.

Tactile Feedback: Using Touch to Diagnose Flow

Touch is another powerful diagnostic sense.

Carefully place your hand on the pump casing and the connecting pipes.

-

Vibration: A working pump will have a slight, steady vibration. Excessive or erratic vibration can signal a problem like a clogged impeller or a failing bearing.

-

Temperature: This is a critical indicator. The pump casing should remain relatively cool to the touch, or at most, slightly warm. The outlet pipe should feel cool, close to the temperature of the source water. If the pump casing becomes hot, shut it down immediately. This means no water is flowing through to cool it, and damage is imminent. A 90% efficient BLDC permanent magnet motor generates less waste heat than older motors, but any motor will overheat quickly without the cooling effect of water circulation.

Visual Inspection: What to Look For

Finally, use your eyes.

Look for any obvious signs of trouble around the pump and its connections.

-

Leaks: Check all pipe fittings, seals, and gaskets for drips or sprays of water. A leak on the suction side can draw in air, causing the pump to lose its prime and stop circulating.

-

Shaft Rotation: On some surface-mounted pumps, you may be able to see the motor shaft spinning. If the shaft is turning but other signs point to no circulation, the issue is likely a blockage, an airlock, or a damaged impeller.

These sensory checks provide immediate feedback and can often pinpoint the problem without requiring any disassembly of the system.

Tools of the Trade: Confirming Circulation with Gauges

Sensory checks are useful, but you need objective data for a definitive diagnosis.

Simple measurement tools remove the guesswork.

Let the numbers tell you the real story of what's happening inside your pipes.

To confirm circulation, check the pressure gauge on the discharge line for a steady, positive reading.

You can also use a clamp-on ammeter to measure the motor's current draw; an abnormally low reading indicates the pump is not moving water.

While your senses can alert you to a problem, instruments provide quantifiable proof.

Pressure gauges and ammeters are the two most fundamental tools for professional pump diagnostics.

They measure the system's hydraulic pressure and the motor's electrical load, respectively.

Together, these two data points create a clear picture of the pump's performance.

An abnormal reading on either of these instruments is a certain sign of a circulation issue.

Understanding how to read them correctly allows you to diagnose problems with a high degree of confidence, whether you are managing a high-flow irrigation system in the Americas or a high-head domestic water supply in a remote part of Africa.

Reading the Pressure Gauge

A pressure gauge installed on the outlet side of the pump is your window into the system's performance.

It measures the force with which the pump is pushing water.

-

Zero or Low Pressure: If the pump is running but the gauge reads zero or a very low number, it's a clear sign that no water is being circulated. This is the most common symptom of an airlock or a complete blockage on the suction side.

-

Fluctuating Pressure: A rapidly vibrating or swinging needle on the gauge often points to an airlock or cavitation. The pump is trying to move a mix of air and water, resulting in unstable pressure.

-

Normal Pressure: A healthy pump will build pressure quickly to a steady level appropriate for its design. A solar screw pump designed for high head (pressure) will show a much higher PSI reading than a high-flow, medium-head solar plastic impeller pump designed for volume. Knowing your pump's expected operating pressure is key to interpreting the gauge correctly.

| Gauge Reading | Possible Cause | Common Impact |

|---|---|---|

| Zero Pressure | No circulation (airlock, suction blockage) | Pump overheating, imminent failure. |

| Low, Steady Pressure | Partial blockage, significant leak | Reduced performance and efficiency. |

| Fluctuating Needle | Airlock, cavitation, insufficient water | Internal pump damage, pipe vibration. |

| High Pressure, No Flow | Downstream blockage (e.g., closed valve) | Dead-heading, motor overload, seal failure. |

The Amperage Test: What the Motor is Telling You

A clamp-on ammeter is a non-invasive tool that measures the electrical current (amps) flowing to the motor.

This reading is directly related to how much work the motor is doing.

-

Low Amperage: Pumping water requires a significant amount of work, which results in a predictable current draw. If the pump is running but not moving water (airlocked or dry), the motor is under very little load. The amperage reading will be significantly lower than the normal operating level, often less than 50% of its rated Full Load Amps (FLA). This is a definitive sign of no circulation.

-

High Amperage: An amperage reading that is higher than the motor's FLA rating indicates an overload condition. This could be caused by a blockage downstream, forcing the pump to work too hard (dead-heading), or a mechanical issue within the pump or motor itself.

This electrical feedback is especially valuable for systems using a high-efficiency BLDC permanent magnet motor.

These motors have a very direct relationship between load and power consumption, making the amperage test an extremely reliable diagnostic indicator.

Smart Diagnostics: Leveraging Modern Pump Controllers

Manual checks are effective, but what if your pump could diagnose itself?

Modern technology has transformed pump diagnostics from a reactive to a proactive process.

Your pump's controller is now its most powerful diagnostic tool.

To check for circulation on a modern system, look at the pump controller's digital display.

It will show real-time data like power output, flow rate, and motor speed, and will display specific error codes for issues like a "dry run" condition.

The true revolution in solar pumping isn't just the pump itself, but the intelligence that controls it.

Systems built around a BLDC permanent magnet motor are managed by an intelligent MPPT (Maximum Power Point Tracking) controller.

This controller functions as the brain of the operation, continuously optimizing performance and, crucially, protecting the equipment.

It constantly monitors dozens of operational parameters, providing a level of insight that was impossible with older, simpler systems.

For distributors and end-users, this means faster troubleshooting, reduced downtime, and a significantly longer service life for the equipment.

This smart technology is what protects investments in high-quality systems, from premium solar stainless steel impeller pumps in Australia to rugged screw pumps in South Africa.

Decoding Controller Data and Error Codes

The controller's display is your new dashboard for pump health.

Instead of guessing, you can see exactly what the system is doing in real-time.

-

Real-Time Performance Metrics: Most smart controllers display key data points. You can see the watts being consumed, the RPM of the motor, the voltage from the solar panels, and on some advanced models, an estimated flow rate (Liters Per Minute or Gallons Per Minute). If the motor is showing high RPM and low wattage, and the flow rate is zero, you have instant confirmation of a no-circulation event.

-

Dry-Run Protection and Alerts: This is one of the most critical protective features. The controller understands the signature power draw of a pump that is not moving water. It recognizes that the low wattage consumption means the motor is under no load. After a short, preset time, it will automatically shut the pump down to prevent burnout and display an error code such as "Dry Run," "Low Power," or "Pump Stall." This turns a potentially catastrophic failure into a simple, non-damaging fault that can be safely investigated.

The Advantage of Hybrid AC/DC Systems

This intelligence extends to more complex power systems as well.

Modern controllers are often AC/DC hybrid compatible.

This means they can be simultaneously connected to solar panels and an AC power source like the grid or a generator.

-

Automated Power Blending: The controller prioritizes solar power, using it whenever available. If solar power is insufficient due to clouds, it will automatically blend in AC power to maintain the required pump performance, maximizing the use of free solar energy.

-

Seamless Switching: When there is no solar input at all (e.g., at night), the controller will automatically switch over to the AC source to ensure a continuous water supply 24/7.

The diagnostic intelligence remains active regardless of the power source.

Whether running on DC solar power or AC grid power, the controller continues to monitor for dry-run conditions, overloads, and other potential faults, providing constant protection for your investment and ensuring a reliable water supply.

This level of sophisticated, automated control and diagnostics is the hallmark of modern, high-performance water pumping systems.

Conclusion

To check for pump circulation, start with sensory checks, then use gauges for data, and finally, consult the smart controller for the most precise and protective diagnostics available.

Frequently Asked Questions

How can you tell if a water pump is working without a gauge?

Listen for the sound of water flowing through the pipes and feel the outlet pipe; it should feel cool and have some vibration if the pump is working correctly.

What are the signs of a failing water pump?

Signs include unusual noises like grinding or whining, frequent tripping of the circuit breaker, reduced water pressure, or the pump getting excessively hot during operation.

Can a water pump run without circulating water?

A pump can run without circulating water, but this "dry run" condition will cause it to overheat and fail very quickly, often within minutes.

How do I increase the circulation of my water pump?

To increase circulation, ensure your pipes are the correct diameter, clean any filters or blockages, and check that the pump is properly sized for the application's flow and pressure requirements.

Why is my pump running but not building pressure?

This is commonly caused by an airlock, a leak in the suction line drawing in air, a clogged intake screen, or a damaged or worn-out impeller.

Does a pump circulator have a reset button?

Some smaller circulator pumps have a thermal overload reset button on the motor housing, but larger submersible or industrial pumps typically do not; they are protected by the external controller.

What causes a circulation pump to stop working?

Common causes include power supply issues, a seized motor due to bearing failure or debris, a tripped thermal overload, or a command from the controller due to a fault condition.

How to test a circulation pump motor?

You can test the motor's windings with a multimeter set to ohms to check for continuity. An open circuit or a short to ground indicates a failed motor.