Tired of pumps that fail prematurely and disappoint customers?

Choosing the wrong pump costs you money, damages your reputation, and leads to endless service calls.

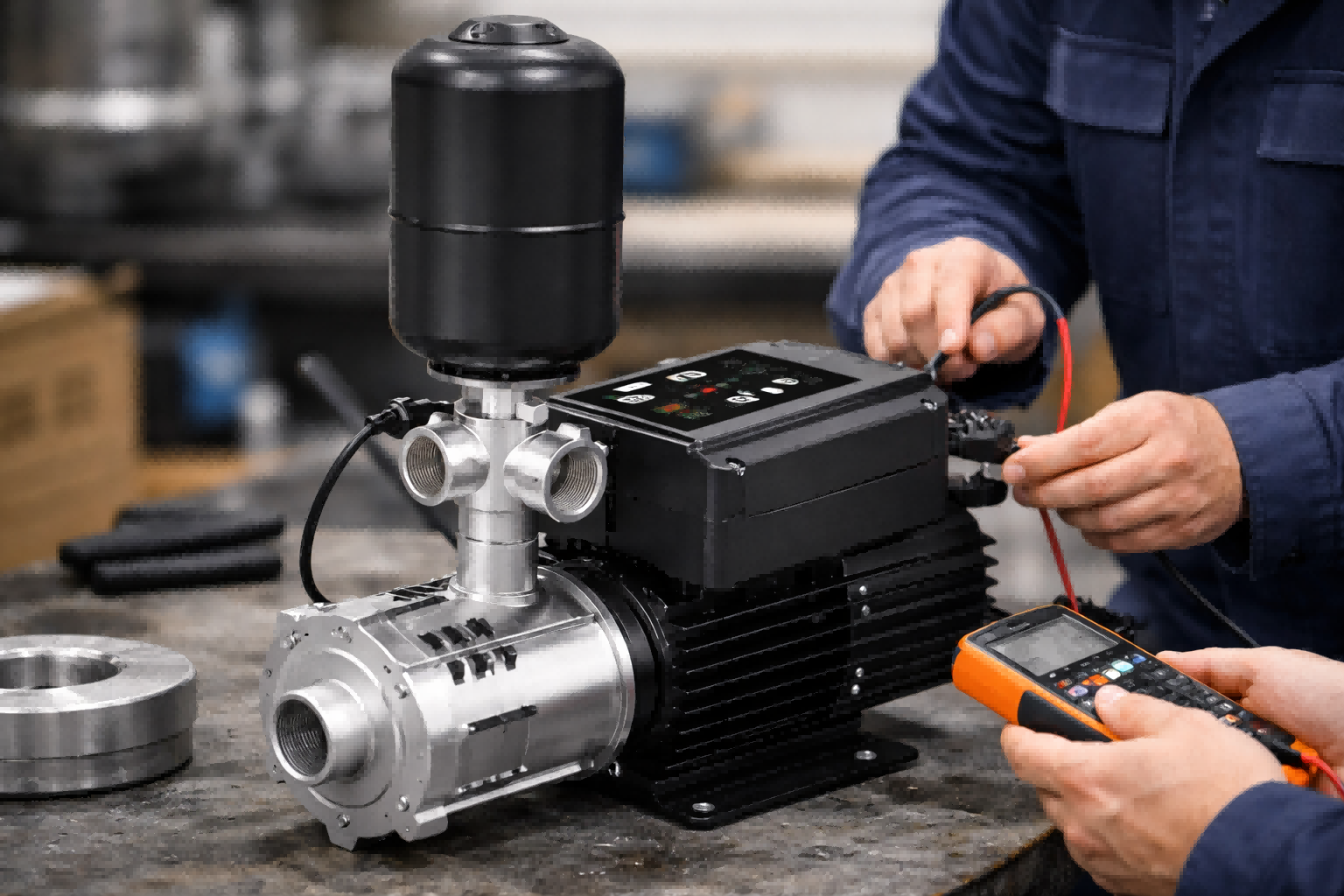

A good water pump has three core traits: a high-efficiency motor (like a BLDC), durable materials matched to the water (e.g., SS304 for corrosion), and an intelligent controller. Quality is in the system's performance, not just its horsepower or price tag.

Many distributors judge a pump by its initial cost or its stated horsepower.

This is a critical mistake.

A truly "good" pump is not a single product, but a complete solution perfectly matched to a specific task.

Its quality is defined by its long-term reliability, its operational efficiency, and its ability to perform under real-world conditions.

To confidently select a pump that delivers value to your customers and enhances your brand, you must learn to look beyond the surface specs.

It requires dissecting the pump into its three most critical components: the pump body materials, the motor that drives it, and the controller that governs its performance.

Understanding these elements is the key to differentiating a truly superior product from a cheap imitation.

Beyond the Motor: Is it Built for the Water?

Your pump failed prematurely despite having a powerful motor.

Corrosive or sandy water completely shredded the internal components, leading to a costly replacement and an unhappy customer.

A good pump uses materials specifically suited for the application. Stainless steel fights corrosion, wear-resistant plastic handles sand economically, and screw mechanisms excel in deep, sandy wells. The material must match the water.

The quality of a pump is not determined by its motor alone.

A high-efficiency motor is useless if the pump's wet end—the part that actually moves the water—disintegrates within a year.

The water itself is an active agent that can be abrasive, corrosive, or both.

A professional-grade pump is designed with this in mind, using specific materials to counteract the challenges of the local water source.

As a distributor, advising your clients on the correct material is one of the most important services you can provide.

It is the difference between selling a product that lasts and one that generates a warranty claim.

The Litmus Test: Water Quality Defines Durability

Before you can judge a pump, you must first judge the water.

The chemical and physical properties of the water source will dictate which pump materials are suitable.

- Corrosive Water: Water with high or low pH levels (acidic or alkaline) will aggressively attack standard metals. This is common in regions with specific geological makeups, like the alkaline soil areas of Australia. Using the wrong pump here is a guarantee of rapid failure.

- Abrasive Water: Water containing sand, silt, or other fine particles acts like liquid sandpaper on a pump's internal components. The impellers and diffusers are particularly vulnerable to wear, which quickly degrades performance and leads to failure. This is a primary concern in many regions of Africa and the Americas.

Material Showdown: Choosing Your Champion

A good product portfolio includes pumps designed for these different conditions, allowing you to offer a tailored solution.

The three primary designs each serve a distinct purpose.

| Pump Type | Primary Application | Key Advantage | Major Limitation | Ideal Water Condition |

|---|---|---|---|---|

| Solar Screw Pump | Deep wells, domestic water, livestock | Excellent sand resistance, very high head | Low flow rate, not for large-scale irrigation | High sand content, deep water table |

| Plastic Impeller Pump | Farm irrigation, pasture water supply | High flow, good fine sand resistance, economical | Not for deep wells or highly corrosive water | Moderate sand, high volume needs |

| SS304 Impeller Pump | Corrosive water, high-end homes, ranches | Superior corrosion resistance, long lifespan | Higher cost and weight, more niche | Acidic or alkaline water, low sand |

For example, a client in a Chilean mining region with acidic water would require a pump with SS304 stainless steel impellers, like certain models in the 4DSC-A/D series.

In contrast, a farmer in South Africa needing to irrigate from a sandy river would be better served by a high-flow plastic impeller pump.

Ignoring this match is the most common reason for premature pump failure.

The Heart of the Matter: Judging the Motor's Efficiency

Your solar pump system cost a fortune, but it barely runs on a cloudy day.

The inefficient motor wastes so much energy that it requires a huge, expensive solar array, and it still underperforms in anything but perfect sunlight.

A good pump is powered by a high-efficiency Brushless DC (BLDC) motor. With over 90% efficiency, it converts more solar energy into water, dramatically reducing solar panel costs and delivering reliable performance.

The motor is the engine of your water pump.

Its ability to convert electrical energy into mechanical power is the single most important factor determining the system's overall efficiency and operating cost.

For a solar-powered system, motor efficiency is everything.

An inefficient motor wastes precious solar energy as heat, forcing you to compensate with more solar panels, which can increase the total system cost by 30% or more.

A superior pump starts with a superior motor.

For distributors, promoting the value of a high-efficiency motor shifts the conversation from price to long-term investment, a language that savvy customers understand.

The Hidden Tax of Inefficiency

Many low-cost pumps use outdated motor technologies that are cheap to produce but expensive to run.

- Brushed DC Motors: These motors use physical carbon brushes that create friction and electrical arcing. Their efficiency rarely exceeds 75%. This means for every 1000 watts of solar power your panels produce, 250 watts or more are lost as useless heat before the pump even begins to move water.

- Standard AC Induction Motors: While robust, these motors are not optimized for solar applications. They are less efficient, especially when run at variable speeds, and require a costly, power-hungry inverter to run on DC solar power.

This wasted energy is a "tax" on your entire system, forcing an oversizing of the power supply and delivering disappointing real-world performance.

The BLDC Motor: A Revolution in Pumping

Modern, high-quality solar pumps are built around a Brushless DC (BLDC) permanent magnet motor.

This technology is a game-changer.

- Over 90% Efficiency: By replacing friction-based brushes with a sophisticated electronic controller and powerful permanent magnets (like 40SH neodymium iron boron), BLDC motors achieve efficiencies over 90%. That same 1000 watts of solar power now delivers 900+ watts of useful work. This means more water pumped per watt of solar.

- Reduced System Cost: A BLDC motor's high efficiency directly translates to a smaller, less expensive solar array. You can achieve the same water output with fewer panels, significantly lowering the barrier to entry for customers.

- Superior Reliability and Lifespan: With no brushes to wear out, BLDC motors are virtually maintenance-free and have a dramatically longer service life. This is a critical selling point for pumps installed in remote, off-grid locations where maintenance is difficult and costly.

- Compact Power: This advanced technology results in a motor that is up to 47% smaller and 39% lighter than a traditional motor of equivalent power, simplifying shipping and installation.

A pump equipped with a BLDC motor isn't just a "good" pump; it's an intelligent investment that pays for itself through lower initial costs and superior performance.

The Brains of the Operation: The Power of a Smart Controller

Your expensive solar pump is great when the sun shines, but useless at night or on cloudy days.

This forces your customers to install a completely separate backup system, doubling their cost and complexity for a simple need: water on demand.

A good pump system includes an AC/DC hybrid controller. It intelligently blends solar with grid/generator power, manages pump speed, and provides diagnostic feedback, ensuring an uninterrupted, efficient 24/7 water supply.

A powerful pump and an efficient motor are only as good as the "brain" that controls them.

In a modern water system, the controller is the most critical component for maximizing performance, protecting the equipment, and ensuring ultimate reliability.

It transforms the pump from a simple on/off device into an intelligent, responsive water management tool.

For a distributor, a pump bundled with an advanced controller is a far more compelling and valuable package.

It solves real-world problems for the end-user, like water availability and energy management, making it an easy sell over more basic, "dumber" systems.

Unlocking Potential with Intelligent Control

A state-of-the-art pump controller provides essential features that define a premium system.

- Maximum Power Point Tracking (MPPT): This is the core intelligence of any solar controller. MPPT technology constantly adjusts the electrical load to extract the absolute maximum wattage from the solar panels, regardless of sun conditions. An MPPT controller can increase a system's daily water output by as much as 30% compared to a simple controller, squeezing every last drop of performance from the solar array.

- Variable Speed and Soft Start: A smart controller allows you to precisely regulate the pump's speed. This prevents the mechanical shock and high-current draw of a hard start, drastically extending motor and pump life. It also allows the user to match the flow rate to the specific need, saving energy.

- Protective Functions: A good controller is also a bodyguard for the pump. It provides critical protections like dry-run prevention, over-voltage, under-voltage, and over-current shutdown, preventing the most common causes of pump failure.

The Ultimate Solution: 24/7 Water with AC/DC Hybrid Power

The pinnacle of modern pump control is the AC/DC hybrid controller.

This technology eliminates the primary weakness of a solar-only system by providing total water security.

It features dual power inputs and operates with smart logic:

- Solar Priority: By default, the system runs on 100% free DC power from the solar panels.

- Hybrid Blending: On overcast days, the controller uses all available solar power first, then intelligently supplements it with the minimum amount of AC power needed from the grid or a generator to maintain performance.

- Automatic AC Takeover: At night or during extended bad weather, the controller seamlessly switches to the AC power source, guaranteeing an uninterrupted water supply 24/7.

This hybrid capability offers the customer the best of both worlds: the cost savings of solar and the absolute reliability of a grid-tied pump.

Conclusion

A good water pump is more than just a motor.

It's a complete system: durable materials, a high-efficiency BLDC motor, and an intelligent AC/DC controller for unmatched performance and reliability.

Frequently Asked Questions

What are the signs of a bad water pump?

Signs include no water flow, low water pressure, constant pump cycling, high electricity bills, and strange noises from the well. These often point to motor failure or a clogged impeller.

How many years should a water pump last?

A good quality well pump should last between 8 and 15 years. However, its lifespan heavily depends on the motor quality, run time, and water conditions.

Can a water pump be repaired?

Yes, many components like pressure switches, capacitors, and sometimes impellers can be repaired or replaced. However, if the motor has burned out, it is often more cost-effective to replace the entire pump.

How do you test a water pump?

Test the pump by checking the pressure switch for proper operation, measuring the amperage draw of the motor to check for overload, and verifying the voltage at the pump.

Why does my water pump keep running?

A pump that won't shut off is usually caused by a leak in the plumbing, a faulty pressure switch, or a pump that is too small or damaged to reach the cut-off pressure.

What causes a water pump to lose pressure?

Pressure loss can be caused by a waterlogged pressure tank, a leak in the system, a clogged impeller or intake screen, or a worn-out pump that can no longer build sufficient head.

Is it worth fixing a 10 year old well pump?

For a 10-year-old pump, replacement is often a better investment. Modern pumps with BLDC motors are significantly more energy-efficient, offering long-term savings that can outweigh the cost of repair.