Struggling with high energy bills and noisy, inefficient machinery?

These systems often run at full power, wasting electricity and causing premature wear.

A Variable Speed Drive (VSD) provides a smarter, more efficient solution.

A Variable Speed Drive, or VSD, is an electronic device that controls the rotational speed of an electric motor.

It works by adjusting the frequency of the electrical power supplied to the motor.

This allows a machine's performance to be perfectly matched to the specific demands of an application.

You now have a basic understanding of what a VSD is.

But its true value becomes clear when you look at the specific benefits it offers.

From massive energy savings to longer equipment life, the advantages are significant.

Let's explore these key uses to see how a VSD can transform your operations.

How Do VSDs Improve Energy Efficiency?

Are your energy costs for pumps and fans constantly rising?

Traditional systems run at one speed, wasting massive amounts of power.

A VSD intelligently matches motor speed to the actual demand, dramatically cutting energy consumption.

A VSD boosts energy efficiency by slowing down a motor when full speed isn't necessary.

In common applications like pumps and fans, this can slash energy consumption by up to 50%.

It achieves this by directly controlling the motor, avoiding inefficient mechanical methods like dampers or throttles.

The core principle behind VSD energy savings in certain systems is fascinating.

It is especially true for centrifugal pumps and fans.

These machines follow a set of rules known as the Affinity Laws.

These laws describe the relationship between the motor speed and the machine's performance.

Understanding the Cube Law

One of the most important Affinity Laws is often called the "Cube Law."

It states that the power a motor needs is proportional to the cube of its speed.

This means a small reduction in motor speed leads to a very large reduction in power consumption.

For example, reducing the motor speed by just 20% (to 80% of its maximum) can reduce the energy required by nearly 50%.

This is because (0.8 x 0.8 x 0.8) equals approximately 0.51, or 51% of the original power.

This powerful relationship is the primary reason VSDs are so effective at saving energy.

VSD vs. Mechanical Throttling

Before VSDs became common, the standard way to reduce flow from a pump or fan was with a mechanical throttle or damper.

Think of it like putting your foot on a car's brake while still holding the accelerator down.

The motor runs at full speed, but a valve or gate physically blocks part of the flow.

All the energy used to generate the blocked flow is converted into wasted heat and noise.

A VSD works much more intelligently.

Instead of blocking the output, it simply tells the motor to slow down.

This reduces the energy being put into the system from the very start.

It is a far more elegant and efficient solution.

| Control Method | Motor Speed | Energy Input | Wasted Energy |

|---|---|---|---|

| Mechanical Throttle | Constant Full Speed | 100% | High (lost to heat/pressure) |

| Variable Speed Drive | Adjusted to Demand | Reduced | Minimal |

Maximizing Efficiency with Advanced Motors

To get the most out of a VSD, it helps to pair it with a highly efficient motor.

Modern systems often use Permanent Magnet Synchronous Motors (PMSM).

These motors are inherently more efficient than traditional induction motors.

When a PMSM is controlled by a sophisticated VSD, the overall system efficiency is maximized.

This combination ensures that every watt of electricity is used as effectively as possible, delivering peak performance with minimal waste.

How Does a VSD Lead to Improved Performance?

Do you struggle with unstable water pressure or inconsistent process speeds?

Manual adjustments are often slow, imprecise, and reactive.

A VSD provides automated, precise, and proactive control over your equipment for superior performance.

A VSD provides exceptionally precise control over a motor's speed and torque.

This precision ensures that a machine operates at its optimal point for any given task.

This translates to more stable pressures, consistent flow rates, and better overall operational quality and reliability.

Improved performance is about more than just efficiency.

It's about achieving stability, precision, and reliability in any application.

A VSD acts as the brain of the motor, making real-time adjustments to meet exact process requirements.

This dynamic control unlocks a new level of performance that fixed-speed systems can never achieve.

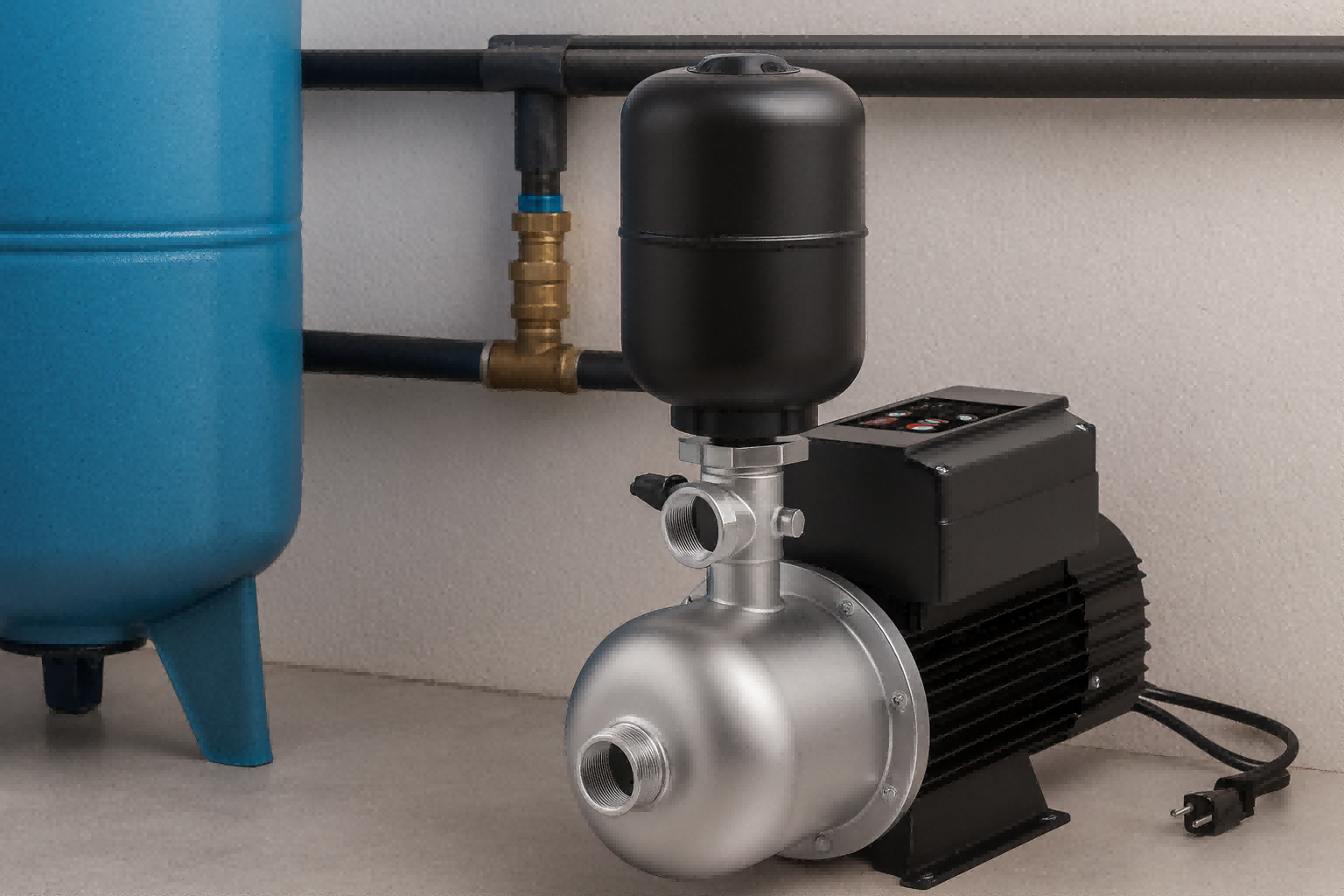

Achieving Constant Pressure in Water Systems

One of the most popular applications for a VSD is in water booster pumps.

In a home or building, demand for water changes constantly as faucets and appliances are used.

Without a VSD, this causes annoying pressure fluctuations.

A VSD-equipped pump uses a pressure sensor to monitor the system in real time.

When a tap opens and pressure starts to drop, the VSD instantly increases the pump's speed to maintain a constant, pre-set pressure.

When the tap closes, it slows the pump down.

This provides a smooth, hotel-like water pressure experience for users.

Precision in Commercial and Industrial Processes

This same principle of precise control is vital in many other fields.

| Application | Performance Improvement | Key Benefit |

|---|---|---|

| HVAC Systems | Exact airflow based on temperature | Stable building climate, energy savings |

| Conveyor Systems | Synchronized speed with production lines | Smooth material flow, less downtime |

| Machine Tools | Optimal cutting speed for materials | Higher quality finish, longer tool life |

| Air Compressors | Air delivery matches pressure demand | Consistent tool pressure, energy reduction |

In conveyor systems, VSDs ensure a smooth flow of materials, preventing jams and synchronizing different parts of a production line.

In machine tools, they allow operators to dial in the perfect cutting speed for different materials, which improves the final product quality and extends the life of expensive cutting tools.

Reliability Under Poor Conditions

The intelligence of a VSD also helps improve performance in another way: reliability.

High-quality VSD systems are designed to operate across a wide range of voltages.

This means that even if the power grid is unstable, with voltage sags or swells, the drive will continue to provide clean, stable power to the motor.

This ensures the equipment performs consistently even when the power supply is not perfect.

This is a critical feature for applications in areas with less-developed electrical infrastructure.

How Does a VSD Reduce Mechanical Stress?

Are you tired of expensive, premature breakdowns of your mechanical equipment?

Starting a motor at full speed creates a massive jolt, stressing every component.

A VSD provides a gentle, controlled start that protects your investment and reduces maintenance costs.

By enabling soft starts and stops, VSDs significantly minimize mechanical stress on components like gears, belts, and couplings.

This gradual acceleration and deceleration reduce the shock and vibration that cause wear and tear.

The result is longer equipment life, fewer breakdowns, and lower maintenance costs.

Every time a standard motor turns on, it's like a hammer blow to the entire system.

The motor attempts to go from zero to full speed almost instantly.

This creates a huge inrush of electrical current and a massive mechanical jolt that travels through shafts, gears, belts, and the machinery itself.

A VSD completely changes this dynamic.

The Power of Soft Starting

A VSD's most important mechanical benefit is its ability to perform a "soft start."

Instead of switching on abruptly, the VSD gradually increases the frequency and voltage to the motor.

This allows the motor to start turning slowly and smoothly ramp up to the desired operating speed over a few seconds.

This gentle acceleration has several benefits:

- Reduces Peak Current: It eliminates the large inrush current associated with direct-on-line starts, which can stress electrical components and cause voltage sags in the facility.

- Minimizes Torque Shock: It prevents the sudden, violent jolt of torque, protecting mechanical parts like gearboxes, couplings, and chains from excessive strain and potential failure.

- Prevents Belt Slippage: In belt-driven systems like fans, a soft start prevents belts from slipping or being stretched during startup.

Mitigating Water Hammer

In pumping systems, a sudden start or stop can create a dangerous phenomenon called water hammer.

This is a hydraulic shockwave that occurs when the moving column of water in a pipe is forced to stop or change direction abruptly.

This shockwave can create a loud banging noise and generate pressure spikes strong enough to break pipes, valves, and fittings.

A VSD's soft start and soft stop capability is the perfect solution.

By gradually accelerating and decelerating the pump, it allows the water column to speed up and slow down gently.

This prevents the formation of destructive pressure waves, protecting the entire plumbing system from damage and leaks.

Built-in Protection Systems

Beyond soft starting, modern VSDs incorporate a suite of intelligent protection functions that act as a 24/7 guardian for the motor and machinery.

These systems constantly monitor operating conditions and can shut the motor down before damage occurs.

| Protection Type | Safeguards Against | Benefit |

|---|---|---|

| Dry Run Protection | Pump running without water | Prevents pump burnout |

| Overcurrent/Stall | Jammed machine or overload | Protects motor windings |

| Overheating | Poor ventilation or overload | Prevents insulation breakdown |

| Voltage Faults | Unstable power grid | Protects electronic components |

These integrated safety features work alongside the soft start function to create a comprehensive shield.

This dramatically extends the life of the equipment and provides peace of mind for operators.

What Are the Wider Applications of a VSD?

Think VSDs are only for a few niche uses?

Many believe they are complex devices for large industrial plants only.

In reality, VSDs are versatile tools used everywhere from homes to factories to improve control and save energy.

A VSD can be used in a vast range of applications.

Any process that involves an electric motor can potentially benefit from VSD control.

Key uses include pumps and fans for managing flow, conveyors for material handling, compressors for optimizing air delivery, and machine tools for precision work.

The versatility of Variable Speed Drives is one of their greatest strengths.

Their ability to precisely control motor speed makes them invaluable in almost any industry you can imagine.

By tailoring the motor's output to the exact needs of the moment, VSDs are optimizing processes all around us.

Let's look at some of the most common applications in more detail.

Pumps and Fans

This is the largest market for VSDs.

In HVAC systems for large buildings, VSDs control fan speeds to deliver just the right amount of conditioned air, maintaining comfort while saving enormous amounts of energy.

In municipal water systems, they are used for two key tasks:

- Water Treatment: VSDs control pumps to manage the flow of water through various filtration and chemical treatment stages with high precision.

- Water Distribution: They are used in booster pump stations to maintain constant water pressure throughout the city's pipe network, even as consumer demand changes throughout the day.

Conveyor Systems and Material Handling

In manufacturing plants and distribution centers, conveyor belts are the arteries of the operation.

VSDs allow the speed of these conveyors to be perfectly controlled.

This is essential for several reasons:

- Synchronization: It allows multiple conveyor lines to merge and run at the same speed, preventing jams and product damage.

- Process Pacing: The speed can be adjusted to match the pace of workers or robotic arms on an assembly line.

- Gentle Handling: For fragile products, the conveyor can be started and stopped slowly to prevent items from falling or breaking.

Compressors and Machine Tools

Air compressors are another area where VSDs deliver big energy savings.

A traditional compressor runs at full speed to fill an air tank, then shuts off.

A VSD-controlled compressor adjusts its motor speed to produce exactly the amount of compressed air being consumed at that moment.

This eliminates wasteful cycling and can reduce energy use by 30% or more.

In machine tools like lathes and milling machines, speed control is critical for quality.

The optimal cutting speed changes based on the material being cut and the type of tool being used.

A VSD gives the operator precise control to set the perfect speed, resulting in a better surface finish, improved accuracy, and longer tool life.

Conclusion

A VSD controls motor speed to match application demand.

This simple function saves energy, improves performance, and extends equipment life, making it a crucial technology in modern systems.

Frequently Asked Questions

What is the main function of a VSD?

A VSD's main function is to control an electric motor's speed by varying the frequency and voltage of its power supply, allowing for precise process control.

Can a VSD save money?

Yes, a VSD saves money by reducing energy consumption, especially in pump and fan applications. It also lowers maintenance costs by reducing mechanical stress on equipment.

What is the difference between a VFD and a VSD?

The terms VFD (Variable Frequency Drive) and VSD (Variable Speed Drive) are often used interchangeably. Both refer to a device that controls motor speed by adjusting electrical frequency.

How does a VSD soft start work?

A VSD soft start works by gradually increasing the voltage and frequency supplied to the motor. This allows the motor to accelerate smoothly, reducing mechanical shock and electrical inrush current.

Are VSDs only for industrial use?

No, VSDs are used in many applications, including residential water booster pumps, commercial HVAC systems, and swimming pool pumps, in addition to industrial machinery.

What is water hammer and how does a VSD help?

Water hammer is a damaging pressure surge in pipes caused by a sudden stop in water flow. A VSD prevents this by gently slowing the pump down.

Do I need a special motor for a VSD?

Most standard induction motors are compatible with VSDs. However, for maximum efficiency and performance, inverter-duty or permanent magnet motors are often recommended.

Can a VSD run a motor faster than its rated speed?

Yes, a VSD can technically run a motor above its base speed by increasing the frequency. However, this can affect motor torque and should be done with caution.