Low water pressure can disrupt daily life and business operations.

This problem can be frustrating and costly.

The right water pump provides a reliable and powerful water flow.

The most common pumps for water supply are centrifugal pumps, including submersible and booster pumps. Centrifugal pumps are versatile and efficient for moving water, while submersible pumps are ideal for wells, and booster pumps increase pressure in existing systems for consistent flow.

Choosing the right pump for a water supply system can seem daunting.

There are many types, each designed for specific situations.

Understanding the key differences is the first step toward making an informed decision.

This guide will break down the primary types of water supply pumps.

We will explore their functions, ideal applications, and the factors you need to consider.

This will help you select the perfect solution for any residential, commercial, or industrial need.

Let's dive into the world of water pumps to find the best fit for your requirements.

What are the main types of water supply pumps?

Struggling to identify the right pump type for your inventory or project?

This confusion can lead to inefficient systems and unhappy customers.

Understanding the main categories simplifies selection and ensures optimal performance.

The main types of water supply pumps are centrifugal, submersible, positive displacement, and booster pumps. Centrifugal pumps are the most common for general water transfer. Submersible pumps work underwater in wells. Positive displacement pumps handle specific flows, and booster pumps increase existing pressure.

To effectively manage water supply, it's crucial to know the primary pump categories.

Each type operates on different principles and is suited for distinct applications.

Making the right choice affects efficiency, longevity, and overall system performance.

Let's break down these categories further.

Pump Classification Overview

Pumps are generally classified based on their mechanical action.

The two main groups are dynamic pumps and positive displacement pumps.

Centrifugal and submersible pumps fall under the dynamic category.

They use a spinning impeller to create velocity and move water.

Positive displacement pumps, on the other hand, trap a fixed amount of fluid and force it out.

Key Characteristics of Each Type

Understanding the core features helps in matching a pump to a job.

A simple comparison can highlight their primary uses.

| Pump Type | Primary Mechanism | Best For | Common Use Case |

|---|---|---|---|

| Centrifugal | Spinning Impeller | High flow rates, general transfer | Municipal water systems, irrigation |

| Submersible | Impeller, Sealed Motor | Deep wells, boreholes | Residential well water, drainage |

| Booster | Impeller (often multistage) | Increasing pressure in a line | Low-pressure homes, tall buildings |

| Positive Displacement | Trapping & Forcing Fluid | Low flow, high pressure, viscous fluids | Dosing systems, oil pumping |

Dynamic vs. Positive Displacement

The fundamental difference lies in how they move water.

Dynamic pumps, like centrifugal models, generate flow by increasing the water's speed.

The flow rate varies significantly with changes in pressure.

They are excellent for moving large volumes of low-viscosity fluids like water.

Positive displacement pumps deliver a constant flow regardless of pressure.

This makes them ideal for applications requiring precise volumes or high-pressure output.

For most general water supply needs, dynamic centrifugal pumps are the industry standard.

They offer a great balance of cost, efficiency, and reliability.

Centrifugal Pumps: The Workhorse of Water Supply

Need a reliable pump for moving large volumes of water efficiently?

Choosing a less common type can be inefficient and costly.

Centrifugal pumps are the industry standard for their versatility and performance.

Centrifugal pumps are the most widely used for water supply due to their simplicity and efficiency. They use a rotating impeller to move water, making them ideal for municipal systems, irrigation, and general building water circulation. They offer a great balance of flow rate and pressure.

Centrifugal pumps are the backbone of modern water supply infrastructure.

Their design is simple, yet highly effective for a wide range of applications.

Understanding how they work reveals why they are so popular.

These pumps convert rotational energy from a motor into the kinetic energy of moving water.

The core components are the impeller and the casing (volute).

How a Centrifugal Pump Works

The process begins when water enters the pump through the inlet, or "eye," of the impeller.

The motor spins the impeller at high speed.

The impeller has curved vanes that catch the water.

As the impeller rotates, it flings the water outward using centrifugal force.

This action creates a low-pressure zone at the impeller's eye, drawing more water in.

The water is forced into the pump casing, known as the volute.

The Role of the Impeller and Volute

The impeller's job is to accelerate the water.

The volute's job is to convert this high velocity into high pressure.

The volute is a specially shaped casing that widens toward the outlet.

As the water moves into this larger area, its speed decreases.

According to Bernoulli's principle, as the velocity decreases, the pressure increases.

This pressurized water then exits the pump through the discharge outlet.

Common Applications

The versatility of centrifugal pumps makes them suitable for many tasks.

- Municipal Water Supply: They are essential for distributing water from treatment plants to homes and businesses.

- Irrigation: Farmers rely on them to move large volumes of water from sources to fields.

- Building Services: They circulate hot and cold water in HVAC systems and provide general water supply.

- Industrial Processes: They move fluids for cooling, processing, and waste management.

Advantages of Centrifugal Pumps

Their widespread use is due to several key benefits.

- High Efficiency: They are very effective at moving large volumes of water.

- Simple Design: They have few moving parts, which means less wear and easier maintenance.

- Reliability: Their robust construction leads to a long operational life.

- Cost-Effective: They offer excellent performance for their price.

For any large-scale water transfer, the centrifugal pump is almost always the right choice.

Submersible Pumps: The Deep Dive Solution

Extracting water from a deep well presents a unique challenge.

Surface pumps struggle with suction lift beyond a certain depth.

Submersible pumps are designed to be submerged, pushing water up from the source.

A submersible pump is a device with a hermetically sealed motor directly coupled to the pump body. It is fully submerged in the fluid it is pumping, typically water in a well or borehole. This design allows it to push water to the surface efficiently from great depths.

When the water source is far below the ground, you need a pump that can handle the depth.

Submersible pumps solve this problem by working directly within the water source.

Unlike surface pumps that pull water up, submersibles push it up.

This pushing action is far more efficient for deep applications.

The entire assembly, including the pump and motor, is submerged.

Design and Operation

A submersible pump is a type of centrifugal pump.

It consists of multiple stacked impellers, known as stages.

Each stage adds pressure to the water.

More stages mean the pump can push water to greater heights, also known as head.

The motor is located below the pump intake and is hermetically sealed.

This seal prevents water from entering the motor and causing damage.

Power is supplied to the motor via a special waterproof electrical cable.

As water is pushed upward through the stages, it travels through a pipe to the surface.

Key Advantages

Submersible pumps offer several distinct benefits over other pump types for deep wells.

- No Priming Required: Because they are already submerged in water, they are self-priming. They do not need to have water manually added to the casing before starting.

- Higher Efficiency: Pushing water is more energy-efficient than pulling it over long vertical distances. They avoid the suction lift limitations that surface pumps face.

- Quiet Operation: Since the pump is located deep underground, its operation is virtually silent at the surface.

- Cavitation Prevention: The pump is submerged under positive pressure from the water above it. This prevents a damaging phenomenon called cavitation, where vapor bubbles form and collapse.

Common Use Cases

Their unique design makes them perfect for specific scenarios.

- Deep Well Pumping: This is their primary application, providing water for homes, farms, and communities from wells and boreholes.

- Sump Pumping: Smaller versions are used in basements to remove floodwater.

- Drainage and Dewatering: They are used on construction sites and in mines to remove unwanted water.

- Wastewater Treatment: Specialized submersible pumps are used to move sewage and sludge.

When sourcing water from deep underground, a submersible pump is the most reliable and efficient choice available.

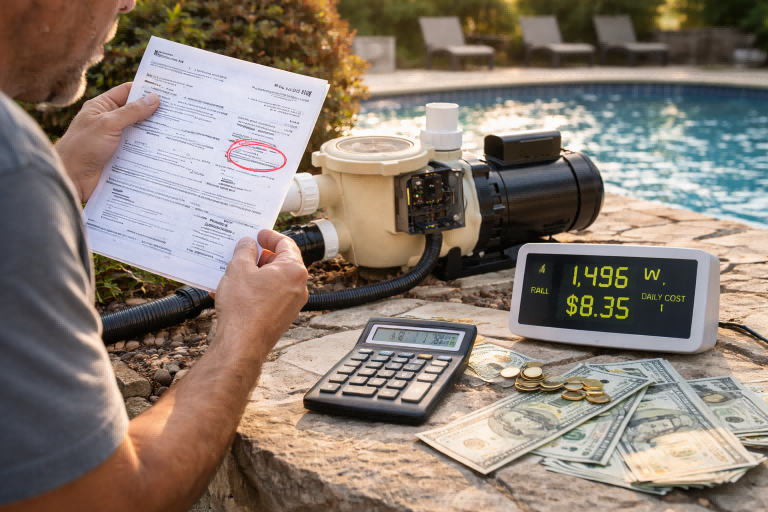

Booster Pumps: Enhancing Water Pressure

Experiencing weak showers and slow-filling appliances is a common frustration.

This low water pressure can impact comfort and system efficiency.

A booster pump is the direct solution to increase and stabilize water pressure.

A booster pump increases the pressure of water within a plumbing system. It works by taking existing low-pressure water and boosting it to a higher, more consistent pressure. They are essential for tall buildings, homes with low municipal supply, and systems requiring specific pressure levels.

A booster pump is not designed to draw water from a source.

Instead, it enhances the pressure of water that is already flowing in a pipe.

Think of it as an amplifier for your water system.

It takes a weak flow and makes it strong and consistent.

This is crucial in many residential, commercial, and industrial settings.

How Booster Pumps Function

Most booster pumps are a type of centrifugal pump.

They have an impeller that spins to increase the velocity and pressure of the water passing through.

A typical booster pump system includes:

- The pump and motor assembly.

- A pressure sensor or switch.

- A controller.

The pressure sensor detects when the water pressure drops below a set level.

When this happens, it signals the controller to turn the pump on.

The pump then runs until the pressure reaches the desired setpoint, and then it shuts off.

This automatic operation ensures that you have strong pressure whenever you need it.

The Rise of VSD Booster Pumps

Modern systems often use a Variable Speed Drive (VSD).

This is a significant advancement over traditional on/off booster pumps.

- Constant Pressure: A VSD pump adjusts its motor speed in real-time. If one faucet is open, it runs slowly. If multiple are open, it speeds up. This maintains a perfectly constant water pressure, regardless of demand.

- Energy Efficiency: By running only at the speed needed, VSD pumps use significantly less electricity. They can reduce energy consumption by up to 50% compared to fixed-speed pumps.

- Reduced Wear and Tear: The "soft start" and variable speed operation reduce mechanical stress on the pump and motor. This extends the lifespan of the equipment and reduces maintenance needs.

- Quiet Operation: VSD pumps are much quieter because they rarely run at full speed.

Where are Booster Pumps Used?

Their ability to solve pressure problems makes them widely applicable.

- Residential Homes: To fix low municipal water pressure or for homes using well water with a storage tank.

- High-Rise Buildings: To ensure strong water pressure on the upper floors, where gravity reduces it.

- Commercial Applications: For hotels, hospitals, and office buildings that need consistent pressure for all users.

- Industrial Processes: In systems that require specific water pressure for operations, like reverse osmosis or high-pressure cleaning.

Investing in a modern VSD booster pump is an investment in comfort, efficiency, and system longevity.

How to Choose the Right Water Supply Pump?

Selecting the wrong pump leads to poor performance and wasted energy.

The technical specifications can be confusing, causing costly mistakes.

A systematic approach focusing on key parameters ensures the perfect match.

To choose the right pump, you must determine the required flow rate (in GPM or L/min) and total dynamic head (the vertical and horizontal distance plus friction loss). Also, consider the water source, fluid type, and power availability to ensure optimal performance and efficiency.

Choosing the right water pump is a critical decision.

It directly impacts the efficiency and reliability of your entire water system.

To make the best choice, you need to analyze your specific requirements carefully.

The two most important factors are the desired flow rate and the required head.

Step 1: Determine Your Required Flow Rate

The flow rate is the volume of water you need the pump to move in a given amount of time.

It is typically measured in gallons per minute (GPM) or liters per minute (L/min).

To calculate this, consider the peak demand of your system.

- For a house: Add up the flow rates of all fixtures that might be used at the same time (e.g., two showers, a dishwasher, and a washing machine).

- For irrigation: Calculate the total water needed by all sprinkler heads or drip emitters operating simultaneously.

- For commercial use: Refer to building codes or engineering specifications for required flow rates.

Choosing a pump with the correct flow rate ensures everyone and everything gets enough water during periods of high use.

Step 2: Calculate the Total Dynamic Head (TDH)

Head is the height to which a pump can raise water.

Total Dynamic Head is the total pressure the pump must overcome.

It is the sum of three components:

- Static Head: The total vertical distance you are moving the water. This includes the vertical lift from the water source to the pump and from the pump to the highest outlet.

- Friction Head: The pressure lost due to friction as water moves through pipes and fittings. Longer pipes, smaller pipe diameters, and more bends all increase friction head.

- Pressure Head: The operating pressure required at the final destination. For example, most homes require about 40-50 PSI at the faucet.

Step 3: Consider Other Critical Factors

Beyond flow and head, other elements are essential for a successful installation.

| Factor | Description | Why It Matters |

|---|---|---|

| Water Source | Is it a deep well, a shallow well, a river, or a storage tank? | This determines if you need a submersible or a surface pump. |

| Fluid Type | Are you pumping clean water, wastewater, or water with solids? | Different pumps are designed for different fluid characteristics. |

| Power Supply | What is the available voltage and phase (e.g., 110V, 220V, single-phase, three-phase)? | The pump's motor must match the available electrical service. |

| Pump Material | Will the pump be exposed to corrosive elements? | Materials like stainless steel or bronze offer better resistance than cast iron. |

By carefully evaluating these factors, you can confidently select a pump that is perfectly sized and suited for your application, ensuring years of reliable service.

The Rise of Smart Pumps and VSD Technology

Traditional pumps run at full speed, wasting energy and causing pressure fluctuations.

This inefficiency leads to high electricity bills and mechanical stress.

Smart pumps with VSD technology provide constant pressure and massive energy savings.

Smart pumps integrate Variable Speed Drive (VSD) technology and intelligent controls. They automatically adjust their motor speed to match water demand, maintaining constant pressure while reducing energy consumption by up to 50%. This technology offers superior performance, efficiency, and a longer lifespan.

The next evolution in pumping technology is here.

Smart pumps are revolutionizing how we manage water supply.

These are not just simple on/off devices.

They are intelligent systems that think, adapt, and optimize their own performance.

The core of this intelligence is Variable Speed Drive (VSD) technology.

What is VSD Technology?

A VSD, also known as a variable frequency drive (VFD), is an electronic controller.

It controls the speed of the pump's electric motor.

Instead of running at a fixed, maximum speed all the time, the VSD adjusts the motor's speed based on real-time system demand.

When demand for water is low, the pump runs slowly.

When demand increases, the pump speeds up.

This simple concept has profound benefits.

The Power of Constant Pressure

One of the biggest advantages for the end-user is constant pressure.

Traditional pumps turn on at full blast when pressure drops to a low point (e.g., 30 PSI).

They run until the pressure hits a high point (e.g., 50 PSI) and then shut off.

This creates noticeable pressure fluctuations in the system.

With a VSD pump, you set a desired pressure (e.g., 45 PSI).

The pump then modulates its speed continuously to maintain that exact pressure.

Whether one faucet is on or ten, the pressure at the tap remains perfectly steady.

Unlocking Massive Energy Savings

The relationship between pump speed and energy use is not linear.

It follows a principle known as the Pump Affinity Laws.

According to these laws, reducing a pump's speed by 20% can reduce its energy consumption by nearly 50%.

Since water demand in most buildings is variable and rarely at its peak, a VSD pump spends most of its time running at a reduced speed.

This translates directly into significant reductions in electricity bills.

For commercial and industrial operators, these savings can be substantial over the pump's lifetime.

Additional Benefits of Smart VSD Pumps

The advantages extend beyond pressure control and energy savings.

- Extended Equipment Lifespan: Soft starting and stopping reduces mechanical shock on the motor, bearings, and seals.

- Advanced Protection: Smart controllers can protect the pump from damaging conditions like running dry, overheating, or electrical surges.

- System Integration: They can be connected to building management systems for remote monitoring and control.

- Quiet Operation: Running at lower speeds makes the pump much quieter, a key benefit in residential and commercial settings.

Smart VSD pumps represent a superior approach to water management, delivering unparalleled comfort, efficiency, and reliability.

Conclusion

Selecting the right pump, from centrifugal to VSD booster models, is vital.

It ensures an efficient, reliable, and pressure-perfect water supply for any application.

FAQs

What is the most common pump for water supply?

The most common pump is the centrifugal pump. Its simple design, efficiency, and versatility make it ideal for moving large volumes of water in most applications.

How do I choose a water pump for my house?

To choose a pump for your house, calculate your peak water demand (flow rate) and the required pressure (head). A VSD booster pump is often ideal for consistent pressure.

What is the difference between a submersible pump and a jet pump?

A submersible pump is placed inside the well and pushes water up. A jet pump is located at the surface and pulls water up, making it suitable for shallower wells only.

How much pressure should a water pump have?

For most residential applications, a pump should deliver between 40 and 60 PSI. The ideal pressure ensures good flow without stressing pipes and fixtures.

Can a pump increase water pressure?

Yes, that is the primary function of a booster pump. It takes the existing water flow and increases its pressure to a higher, more useful level.

How long does a water pump last?

A well-maintained quality water pump can last from 10 to 15 years. Factors like water quality, usage frequency, and proper installation affect its lifespan.

What is a VSD pump?

A VSD (Variable Speed Drive) pump automatically adjusts its motor speed to match water demand. This provides constant pressure and significant energy savings compared to standard pumps.