Choosing the wrong solar pump for your customers' farms leads to system failures and lost sales.

This damages your reputation and costs you money.

To succeed, you must understand which pump type solves specific agricultural challenges, securing customer trust.

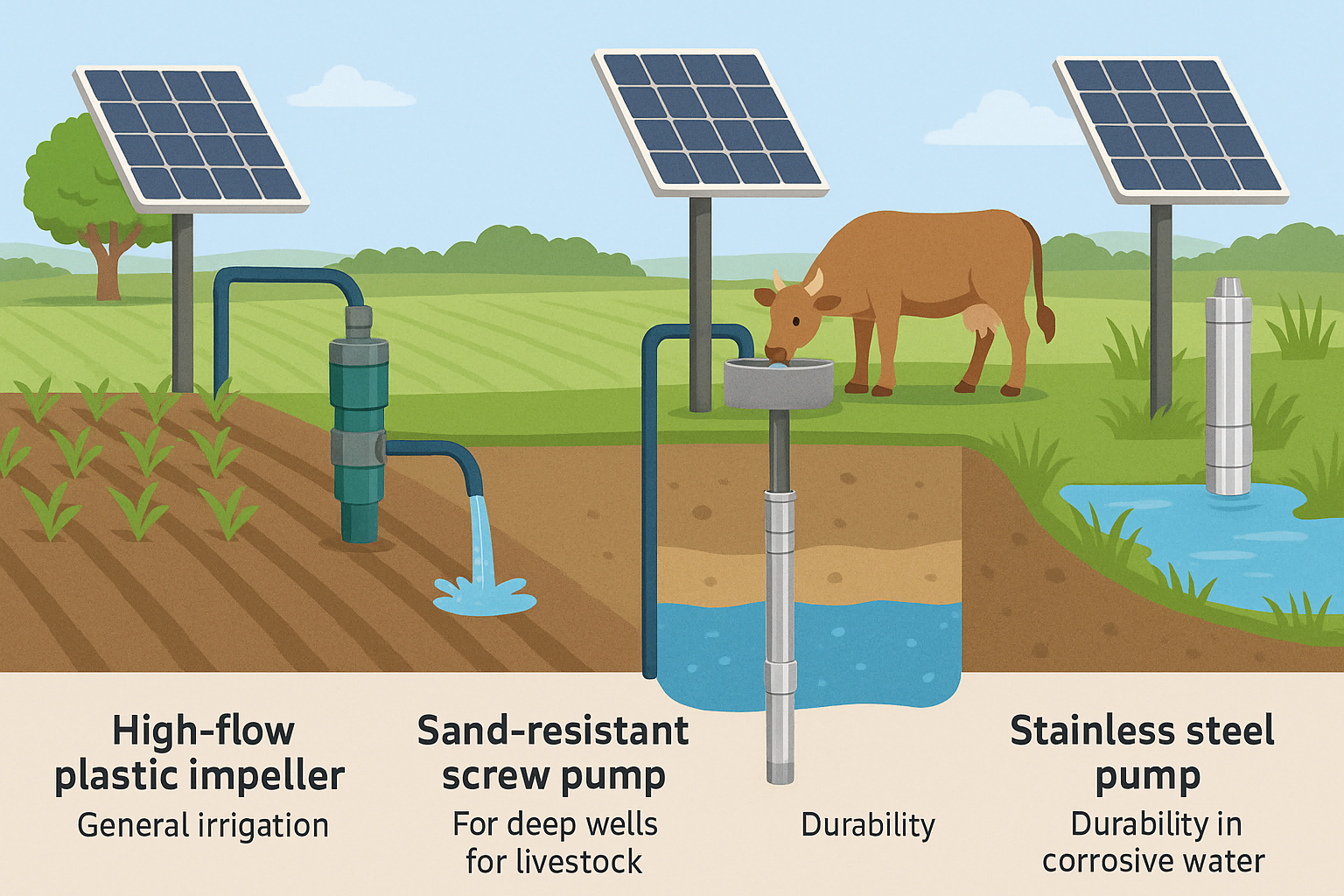

The best solar pump for agriculture depends on the specific need.

High-flow plastic impeller pumps are ideal for general irrigation, sand-resistant screw pumps excel in deep wells for livestock, and stainless steel pumps provide durability in corrosive water, ensuring a reliable solution for every farm.

But the pump itself is only one part of the equation.

To truly equip your customers with the best solution, you need to understand the technology that drives these pumps.

You also need to know how to match a specific pump type to a specific farming scenario.

Let's explore the powerful portfolio that can meet every agricultural water demand.

This knowledge will empower you to become a trusted solutions provider, not just a seller.

The Workhorse: When is a Solar Plastic Impeller Pump the Best Choice?

Farmers need to move large volumes of water for irrigation without breaking the bank.

Inefficient pumps waste precious solar energy and fail to deliver the required flow, threatening crop yields.

A high-flow solar plastic impeller pump provides the perfect balance of performance and value.

A solar plastic impeller pump is best for high-volume farm irrigation and livestock water supply.

Its design prioritizes flow rate and cost-effectiveness, making it the ideal workhorse for general agricultural applications with moderate well depths and non-corrosive water.

This pump is the backbone of many agricultural water systems around the world.

Its primary function is to move a lot of water quickly and efficiently.

It uses a multi-stage centrifugal design.

Inside the pump, a series of precisely engineered plastic impellers spin at high speed.

Each impeller adds pressure to the water, pushing it upwards.

This method is perfect for generating high flow rates at moderate pressure.

It's the ideal technology for surface-level irrigation or drawing water from wells that are not excessively deep.

For a distributor, this pump represents the largest market segment.

It solves the most common problem for farmers in Africa and the Americas: getting enough water to their crops and animals every single day.

Its simple, robust design ensures reliability, while its economic price point makes it an accessible solution for a wide range of customers.

Understanding the Technology

The pump's effectiveness comes from its multi-stage centrifugal system.

Think of it as a series of fans stacked on top of each other, all pushing water in the same direction.

- Multi-Stage Design: Each stage contains an impeller and a diffuser. The impeller accelerates the water, and the diffuser slows it down, converting velocity into pressure. More stages mean more pressure, allowing the pump to lift water from deeper sources.

- Engineered Plastic Impellers: Modern pumps use high-strength, wear-resistant polymers. This material offers an excellent balance of durability and cost. It is lightweight, which reduces the motor's starting load, and it handles fine sand much better than softer metals.

Ideal Applications in Agriculture

This pump is versatile, but it truly shines in high-volume scenarios.

The key is matching its high-flow, medium-head characteristics to the right job.

- Large-Scale Crop Irrigation: This is the pump's primary application. It can supply enough water for sprinklers, flood irrigation, or large drip systems, covering many acres of farmland.

- Pasture Water Supply: It can quickly fill large storage tanks that then feed multiple watering troughs for cattle, sheep, or other livestock across vast pastures.

- Aquaculture: Fish and shrimp farms require constant water circulation and replenishment. This pump can provide the necessary flow to maintain healthy pond environments.

Key Advantages for Your Customers

When talking to a farm owner, focusing on practical benefits is key.

| Feature | Advantage for the Farmer | Why It Matters for Your Business |

|---|---|---|

| High-Flow Performance | Waters crops and livestock faster, improving farm efficiency. | Meets the biggest need in the agricultural market. |

| Excellent Wear Resistance | Lasts longer in wells with fine sand, reducing replacement costs. | Builds a reputation for providing durable, reliable products. |

| Economic Value | Lower initial investment provides a faster return on investment. | Offers a competitive price point, helping you win more deals. |

This combination of performance and value makes the solar plastic impeller pump an essential product in any agricultural distributor's portfolio.

The Deep Well Specialist: Why Choose a Solar Screw Pump?

Many farms and rural homes rely on deep wells where standard pumps simply can't reach.

A pump failure deep underground is a costly disaster, leaving crops and animals without water.

A solar screw pump is engineered specifically for these high-head, high-stakes situations.

Choose a solar screw pump for deep wells and high-lift applications.

Its positive displacement design creates immense pressure to lift water from great depths, making it perfect for livestock watering and small-scale drip irrigation where well depth is the main challenge.

The solar screw pump operates on a completely different principle than a centrifugal pump.

It does not throw water with an impeller.

Instead, it uses a mechanism called positive displacement.

This design is brilliantly simple and incredibly effective for creating high pressure.

Inside the pump is a single helical rotor made of stainless steel, which looks like a corkscrew.

This rotor turns inside a tough, flexible rubber stator.

As the screw turns, it forms sealed cavities of water between it and the stator wall.

These cavities move progressively up the pump, pushing the water in front of them.

This process is like an Archimedes' screw, but it generates enormous pressure.

This pressure allows the pump to lift water from hundreds of meters deep, far beyond the capability of most impeller pumps.

This makes it the go-to solution for arid regions in Africa and Latin America, where the water table can be very low.

It provides a lifeline for domestic use, livestock, and specialized irrigation.

The Power of Positive Displacement

The core strength of the screw pump is its method of moving water.

It traps and pushes a fixed volume of water with each rotation.

- High Head Capability: This design is inherently high-pressure. The pump's lifting capability (head) is determined by its length, not its speed. This allows it to efficiently pump from very deep wells even with limited solar power.

- Consistent Flow: Unlike centrifugal pumps, the flow rate of a screw pump is less affected by the head. It delivers a steady, non-pulsating stream of water, which is ideal for drip irrigation systems.

Unmatched Sand Resistance

One of the biggest problems in boreholes is sand, which can quickly destroy an impeller.

The screw pump excels in these conditions.

The rubber stator is slightly flexible.

If a grain of sand enters a cavity, the stator can deform slightly to let it pass without causing significant damage.

The slow, grinding action is far less susceptible to abrasion than the high-speed spinning of an impeller.

This makes it the most durable choice for newly drilled or sandy wells.

Core Agricultural Use Cases

While not a high-flow pump, it is a powerful specialist tool.

| Application | Why the Screw Pump is Ideal | Target Market |

|---|---|---|

| Deep Well Livestock Water | Can lift water to a surface tank from a very deep borehole. | Ranches in arid regions (e.g., Africa, Mexico). |

| High-Pressure Drip Irrigation | Provides the pressure needed for small, efficient drip systems. | Small-scale, high-value crop farming. |

| Remote Farmhouse Supply | Delivers reliable domestic water from deep wells off-grid. | Any rural homestead without access to city water. |

By offering the solar screw pump, you show your customers that you can solve their most difficult water challenges, building your reputation as an expert.

The Premium Problem-Solver: Is a Stainless Steel Pump Necessary?

Certain regions have aggressive, corrosive water that quickly eats away at standard pumps.

Frequent pump replacements are expensive, time-consuming, and destroy customer trust in your products.

A durable solar stainless steel impeller pump is the ultimate solution for these harsh environments.

A solar stainless steel impeller pump is necessary for farms with acidic, alkaline, or otherwise corrosive water.

Its superior SS304 construction provides maximum longevity and reliability, protecting the farmer's investment and your brand's reputation in high-value or challenging applications.

The stainless steel impeller pump is the premium offering in a professional solar pump portfolio.

Functionally, it is a multi-stage centrifugal pump, just like the plastic impeller model.

It is designed to produce high flow rates at medium-to-high head.

The crucial difference lies in the material.

Every component that touches water—the pump body, the impellers, the shaft, and the outlets—is constructed from high-grade SS304 stainless steel.

This material is specifically chosen for its outstanding resistance to corrosion and rust.

This pump is not for every customer.

It is a specialized solution designed for environments where a standard pump would quickly fail.

Consider regions with unique soil chemistries, like the alkaline soils found in parts of Australia, or areas with acidic water due to geological factors.

In these places, a standard pump might last only a year or two.

A stainless steel pump is engineered to last for a decade or more in the exact same conditions.

Offering this product positions your business as a provider of high-quality, long-term solutions.

It caters to high-end customers and those with difficult water challenges, opening up niche markets where price is secondary to reliability and longevity.

Why Material Matters: Corrosion Resistance

Corrosion is an electrochemical process that degrades metals.

Water with a high or low pH (alkaline or acidic) accelerates this process dramatically.

- SS304 Stainless Steel: This alloy contains high levels of chromium and nickel. The chromium creates a passive, invisible, and self-healing layer on the steel's surface. This layer protects the iron in the steel from reacting with water and oxygen, thus preventing rust and corrosion.

- Longevity and Purity: A corrosion-resistant pump not only lasts longer but also ensures water purity. It does not leach rust or other metallic compounds into the water supply, which is critical for drinking water and sensitive crops.

Premium Agricultural and Domestic Applications

This pump is the best choice when long-term reliability is the absolute top priority.

| Application | Why Stainless Steel is a Must | Target Customer |

|---|---|---|

| Farms with Corrosive Water | Resists damage from acidic or alkaline water, ensuring long life. | Farmers in regions with known water quality issues (e.g., Australia). |

| High-End Ranches & Estates | Provides a "best-in-class" solution for critical water supply. | Owners who demand premium quality and maximum durability. |

| Domestic Water Supply | Guarantees clean, rust-free water for household use. | Any customer who prioritizes water purity and system longevity. |

Justifying the Investment

While the initial cost is higher, the long-term value is undeniable.

You are selling peace of mind.

For a customer in a region with corrosive water, a stainless steel pump is not a luxury; it is the most cost-effective solution over the long run.

The total cost of ownership is far lower when you eliminate the need for frequent and costly pump replacements.

Stocking this pump demonstrates your commitment to quality and your ability to serve the entire market, from the most budget-conscious to the most demanding customers.

The Core Advantage: What Drives These Pumps?

Even the best pump is useless without a powerful and efficient motor.

An inferior motor wastes solar energy, requires more panels, and fails prematurely, creating headaches for everyone.

The true competitive advantage of a top-tier solar pump system lies in its advanced motor technology.

The heart of a leading solar pump system is a high-efficiency Brushless DC (BLDC) permanent magnet motor.

This core technology, with over 90% efficiency, reduces the number of solar panels needed, eliminates maintenance, and ensures a long, reliable service life for any pump it drives.

The motor is the engine that converts electrical energy from the solar panels into the mechanical power that pumps water.

Its performance dictates the overall efficiency and reliability of the entire system.

A superior solar pump manufacturer is, first and foremost, a motor technology expert.

All three of the agricultural pumps we have discussed—plastic impeller, screw, and stainless steel—are powered by the same advanced motor technology: the Brushless DC (BLDC) permanent magnet motor.

This is not just an incremental improvement; it is a fundamental leap forward from older motor types.

Traditional DC motors rely on carbon brushes to transmit power to the rotor.

These brushes are a point of friction, wear, and eventual failure.

They are the single most common reason for motor maintenance and breakdown.

BLDC motors eliminate these brushes completely.

Power is delivered electronically via a smart controller, resulting in a motor with no wearable parts.

This makes it virtually maintenance-free—a massive advantage for a pump that might be installed 100 meters underground.

Unlocking Efficiency: The Power of Permanent Magnets

The incredible efficiency of these motors, often exceeding 90%, comes from their use of powerful permanent magnets.

- Core Materials: The rotor is constructed with high-strength neodymium iron boron (NdFeB) magnets. These are the strongest type of permanent magnets commercially available.

- How It Works: Because the rotor is permanently magnetized, the motor does not need to expend any energy creating a magnetic field in the rotor. Nearly all the electrical energy is converted directly into rotational force (torque).

What This Means for Your Customers

High efficiency is not just a technical specification; it is a direct financial benefit for the end-user.

| Motor Feature | Direct Customer Benefit |

|---|---|

| >90% Efficiency | Fewer Solar Panels Needed: Lowers the total system cost significantly. |

| High Torque | Reliable Starting: The pump starts easily even in low light. |

| Brushless Design | Zero Maintenance: Eliminates the most common point of failure. |

| Compact & Lightweight | Easier Installation: Reduces labor time and costs. |

| Cooler Operation | Longer Lifespan: Less wasted energy as heat means less stress on components. |

By offering pumps powered by this superior motor technology, you provide a system that is cheaper to buy, easier to install, and more reliable over its entire lifespan.

The motor is the invisible engine of value, and it is the single most important factor in the system's performance.

Conclusion

The best agricultural solar pump is not a single product.

It is a flexible portfolio driven by high-efficiency motor technology.

This approach allows you to solve every customer's unique water challenge effectively and reliably.

FAQs

Can a solar pump work without a battery?

Yes, most agricultural solar pumps are designed to work directly from solar panels without batteries.

They pump water when the sun is shining and stop when it gets dark, effectively storing energy as water in a tank.

How do I choose a solar water pump for my farm?

First, determine your required water volume (flow) and the vertical distance you need to lift it (head).

Then, consider your water quality.

This will help you choose between a high-flow, high-head, or corrosion-resistant pump model.

How long do solar pumps last?

A high-quality solar pump system can last for over 10 years.

The BLDC motor is maintenance-free, and solar panels are often warrantied for 25 years.

The pump itself is the main component that may eventually need service.

Can solar pumps run AC and DC?

Yes, advanced systems use a hybrid AC/DC controller.

This allows the pump to use solar power when available and automatically switch to grid or generator power at night or on cloudy days, ensuring a 24/7 water supply.

How many solar panels do I need for a 1 hp water pump?

The number of panels depends on their wattage and the motor's efficiency.

For a high-efficiency 1 hp (750W) BLDC motor, you would typically need around 900W to 1000W of solar panels to ensure good performance even in less-than-ideal sunlight.

Are more expensive solar pumps better?

Not always.

Price often reflects the materials and application.

A more expensive stainless steel pump is better for corrosive water, but an economical plastic impeller pump is often the best and most cost-effective choice for general irrigation.