The 4 Ultimate Secrets to Maximizing the Efficiency of Your Solar Water Pump?

Struggling with high energy bills and unreliable water access? You feel stuck with old, fuel-guzzling pumps. A modern solar water pump offers a powerful, efficient, and cost-effective solution.

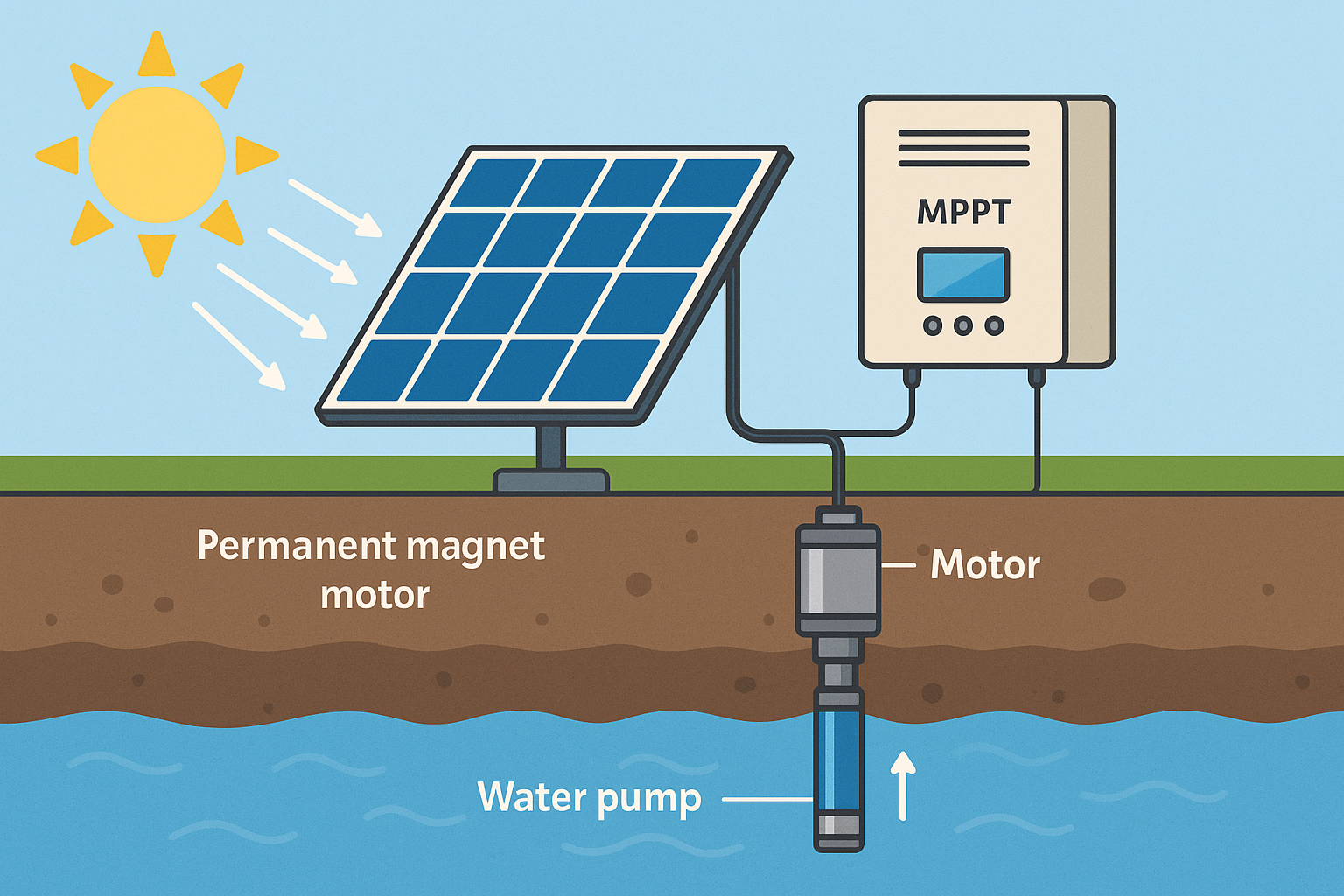

The overall efficiency of a solar water pump is a direct result of its core components, especially the motor and inverter, combined with external factors like sunlight and system design. Choosing a permanent magnet motor and an MPPT inverter is the first step to maximizing performance and long-term savings.

Getting the most out of your investment in solar technology is my top priority. As an engineer who has spent over a decade in this field, I've seen firsthand what separates a good solar pump system from a great one. It's not just about slapping some solar panels on a pump. It’s about understanding the synergy between every component to achieve peak performance. The journey to water independence and lower costs starts with understanding the fundamentals that drive the incredible efficiency of a solar water pump. Let's dive into the details that truly make a difference, so you can make an informed decision that will benefit you for years to come.

Why is a Permanent Magnet Motor a Game-Changer for Solar Pump Efficiency?

Are your current water pumps consuming too much power? This wasted energy translates directly into higher costs and lower water output, a frustrating cycle. Modern motor technology offers a simple, powerful upgrade.

A permanent magnet synchronous motor (PMSM) fundamentally improves the efficiency of a solar water pump. Unlike older asynchronous motors, a PMSM doesn't waste energy creating its own magnetic field, meaning more of your valuable solar power goes directly into moving water.

When I first started in this industry, most pumps used traditional asynchronous (or induction) motors. They were the standard, but they had a built-in inefficiency. They need to use a portion of the incoming electrical energy just to induce a magnetic field in the rotor. This is wasted energy. It generates heat and doesn't contribute to the pump's work. The real breakthrough for solar applications was the widespread adoption of the Permanent Magnet Synchronous Motor, or PMSM.

The Core Difference: How PMSM Outperforms Asynchronous Motors

The name says it all. A "permanent magnet" motor has strong magnets built directly into its rotor. Because the magnetic field is permanent, the motor doesn't need to spend any energy creating one. All the electrical power from the solar panels can be dedicated to making the rotor spin and, in turn, pumping water. This single change has a massive impact on the overall efficiency of a solar water pump system. Think of it like a car. An asynchronous motor is like a car that has to burn a little gas just to keep its own engine parts running, even before it starts moving the wheels. A PMSM is like an electric car where nearly all the battery power goes directly to turning the wheels. This means less energy is wasted as heat, leading to a cooler-running and longer-lasting motor.

Quantifying the Efficiency Gains

This isn't just a minor improvement. The numbers are significant. We've seen in our own testing at Rafsun that a PMSM can be up to 30% more efficient than a comparable asynchronous motor. This is a huge leap. For a user, this means you can get 30% more water for the same amount of sunlight, or you can achieve your target water output with a smaller, less expensive solar panel array. This directly impacts both the performance and the initial cost of the system.

Here’s a simple comparison to illustrate the impact on the efficiency of a solar water pump:

| Feature | Asynchronous Motor | Permanent Magnet Synchronous Motor (PMSM) |

|---|---|---|

| Rotor Magnetism | Induced by stator, requires energy | Built-in permanent magnets, no energy needed |

| Energy Waste | Higher, due to induction and heat loss | Lower, minimal heat loss |

| Typical Efficiency | 70-85% | 85-95% |

| Power-to-Size Ratio | Lower | Higher (more compact for the same power) |

| Performance in Low Light | Struggles, can stall easily | Better, can operate at lower speeds |

My Personal Experience: The 'Aha!' Moment with PMSM

I remember visiting a sugarcane plantation in Thailand a few years ago. The farm manager, let's call him Jacky, was an experienced engineer himself. He was frustrated with his diesel pumps. They were expensive to run and unreliable. He was skeptical about solar, worried it wouldn't be powerful enough. We installed a 2.2kW solar pump system with one of our PMSM motors. The first time we turned it on, even in the partial morning sun, the water flow was strong and steady. Jacky's face lit up. He saw immediately that the motor was converting that limited morning sunlight into real work, not just wasting it. That's the tangible benefit that improves the efficiency of a solar water pump.

How Do Inverters Unleash the Full Efficiency of a Solar Water Pump?

Solar power is fantastic, but it's not constant. Clouds pass by, the sun rises and sets. This fluctuation can make a simple pump run poorly or stop altogether, wasting precious sunlight.

A solar pump inverter is the brain of the system, crucial for efficiency. It uses Maximum Power Point Tracking (MPPT) to constantly pull the most energy possible from the panels and converts it into the perfect power for the motor, ensuring optimal performance all day long.

A great motor is only half the battle. To truly maximize the efficiency of a solar water pump, you need an intelligent controller to manage the power source. Solar panels don't produce a fixed voltage and current; it changes constantly with the amount of sunlight hitting them. Connecting a pump motor directly to panels is incredibly inefficient. The motor would only run well for a very brief period around noon on a perfectly clear day. The rest of the time, the power mismatch would cause it to stall or run far below its potential. This is where the solar pump inverter comes in. It's a sophisticated piece of technology that acts as the perfect middleman between the panels and the motor.

What Exactly is MPPT and How Does it Work?

MPPT stands for Maximum Power Point Tracking. It is arguably the most critical feature for the efficiency of a solar water pump. Every solar panel has an optimal operating point—a specific combination of voltage and current—where it produces the absolute most power. This "maximum power point" shifts throughout the day with changes in sunlight and temperature. An inverter with MPPT technology has a smart algorithm that is constantly monitoring the panels. It thousands of times per second asks, "Am I getting the most power I possibly can right now?" It then adjusts the electrical load to force the panels to operate at that perfect point. It’s like constantly re-tuning a radio to get the clearest, strongest signal. Without MPPT, a system can lose 20-30% of its potential power. With MPPT, you are ensuring that every available watt of sunlight is captured and sent to your motor.

The Power of VFD: Matching Pump Speed to Available Sunlight

Another key function of the inverter is Variable Frequency Drive (VFD). The inverter takes the DC power from the panels and converts it into AC power that the motor uses. But it doesn't just create a standard, fixed AC signal. VFD allows the inverter to change the frequency of the AC power. Why does this matter? The speed of a PMSM motor is directly tied to the frequency of the electricity it receives. By varying the frequency, the inverter can make the pump run faster or slower. This is a game-changer for efficiency.

- In the early morning or on a cloudy day: Sunlight is weak. The MPPT extracts what little power it can, and the VFD tells the motor to run slowly. It doesn't try to run at full speed and stall. Instead, it pumps a smaller, steady amount of water.

- At high noon on a clear day: Sunlight is strong. The MPPT is pulling maximum power, and the VFD tells the motor to run at full speed, pumping the maximum volume of water.

This ability to adapt means the pump runs for more hours of the day and doesn't waste energy trying to do the impossible. It smoothly matches its workload to the available solar energy, which dramatically increases the total amount of water pumped from sunrise to sunset. This dynamic adjustment is fundamental to achieving high daily operational efficiency in a solar water pump.

Can Higher Initial Costs Truly Lead to Better Long-Term Solar Pump Efficiency and Savings?

Seeing the upfront price of a solar water pump system, especially the solar panels, can make anyone pause. It looks much more expensive than a simple diesel pump, causing hesitation.

Yes, absolutely. While the initial cost is higher, the incredible long-term efficiency of a solar water pump delivers significant savings. By completely eliminating the endless expense of fuel for generators, the system pays for itself, often in as little as three years.

It's one of the first questions I always get from potential customers. They see the price tag for the pump, the inverter, and especially the solar panels, and compare it to the cost of a standard pump and diesel generator. On day one, there's no question that the solar option requires a larger capital investment. But that's a dangerously shortsighted view. The true cost of a water pumping system isn't what you pay on day one; it's the total cost of ownership over its entire lifespan. The operational efficiency of a solar water pump isn't just about how well it converts sunlight to water flow; it's also about its economic efficiency over time.

Breaking Down the Numbers: A Real-World Example

Let's put some real numbers to this. I often use the example of one of our popular 2.2kW (3 HP) pump systems, as it's a common size for small farms and community wells. We can compare the total cost over five years for our solar pump versus a comparable diesel-powered pump.

Here is a simplified cost breakdown. Note that fuel prices and usage can vary, but this illustrates the principle. Let's assume the diesel pump runs for 6 hours a day and consumes 1.5 liters of fuel per hour.

| Cost Item | Solar Pump System | Diesel Pump System |

|---|---|---|

| Initial Investment | ~ $2,500 (Pump, Inverter, Panels) | ~ $1,000 (Pump, Generator) |

| Year 1 Fuel Cost | $0 | ~ $3,285 (9L/day @ $1/L for 365 days) |

| Year 2 Fuel Cost | $0 | ~ $3,285 |

| Year 3 Fuel Cost | $0 | ~ $3,285 |

| Year 4 Fuel Cost | $0 | ~ $3,285 |

| Year 5 Fuel Cost | $0 | ~ $3,285 |

| 5-Year Maintenance (Est.) | ~ $100 (Minimal) | ~ $1,000 (Oil, filters, repairs) |

| Total 5-Year Cost | ~ $2,600 | ~ $18,425 |

As you can see, the diesel pump system ends up costing more than seven times as much over just five years. The solar pump system pays for itself—what we call the Return on Investment (ROI)—in less than a year when you factor in fuel costs. My initial estimate of payback in three years is actually very conservative; for heavy users, it's much faster. This is the power of operational efficiency translating directly into financial efficiency.

Beyond Fuel: The Hidden Costs of Traditional Pumps

The table above doesn't even tell the whole story. The "cost" of a diesel pump goes beyond just fuel and maintenance. There's the cost of labor and time. Someone has to transport fuel to the site, often daily. Someone has to perform regular oil changes and maintenance. When a generator breaks down, which they often do, you have crop-threatening downtime and expensive repair bills. This is what Jacky, the sugarcane engineer, was dealing with. His team was spending hours every week just managing their fuel supply and fixing their generators. With the solar pump, it's installed once. It turns on with the sun and turns off at sunset. The reliability and peace of mind have a value that's hard to put on a spreadsheet, but it's very real for the user.

What 7 External Factors Shockingly Impact Your Solar Water Pump's Efficiency?

You've bought a top-tier motor and inverter, but your pump's output is disappointing. It's a frustrating mystery when the hardware is right but the results are wrong, leaving you questioning your investment.

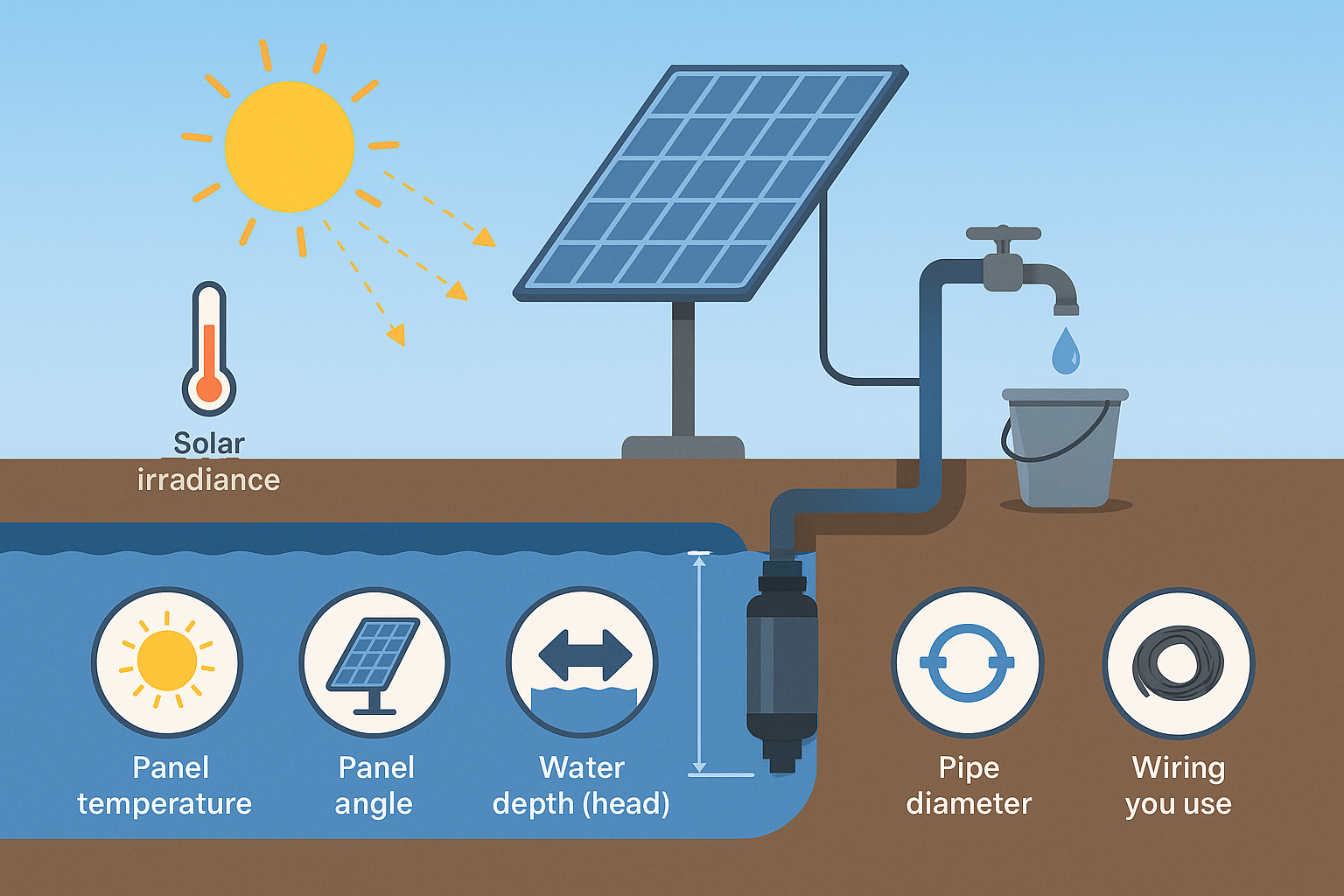

Even the best hardware can underperform. The practical efficiency of a solar water pump is critically impacted by 7 external factors: solar irradiance, panel temperature, panel angle, water depth (head), pipe diameter, water quality, and even the wiring you use.

After a decade of troubleshooting systems in over 150 countries, I can tell you that a lot of performance issues have nothing to do with the pump itself. A solar water pump is part of a larger ecosystem. Optimizing its efficiency means looking beyond the motor and inverter to the environment and the installation itself. You can have the best engine in the world, but it won't perform well with bad fuel or flat tires. The same principle applies here. Paying close attention to these external factors is what separates a basic installation from a high-performance system that delivers water reliably for decades.

The 7-Point Checklist for System Efficiency

I've developed a mental checklist that I run through for every project. This ensures we are maximizing the potential of the hardware we are installing. Overlooking even one of these can create a bottleneck that cripples the entire system's performance.

| Factor | Impact on Efficiency of Solar Water Pump | How to Optimize |

|---|---|---|

| 1. Solar Irradiance | This is your "fuel." Lower irradiance (cloudy days, winter) means less power available. | Choose a location with zero shading from trees or buildings. The system's output will naturally vary by season. |

| 2. Panel Temperature | Solar panels lose efficiency as they get hotter. A very hot panel can produce 15-20% less power than a cool one. | Mount panels with a few inches of air gap underneath to allow for cooling airflow. Don't mount them flat on a hot roof. |

| 3. Panel Angle & Orientation | Incorrect angle or direction means panels won't capture the maximum amount of direct sunlight. | Angle panels to match your latitude and face them directly towards the equator (South in the Northern Hemisphere, North in the Southern). |

| 4. Total Dynamic Head (TDH) | This is the total pressure the pump must overcome (vertical lift + pipe friction). Higher head requires more energy. | Accurately calculate TDH before selecting a pump. Underestimating it is a common cause of poor flow. |

| 5. Pipe Diameter | Narrow pipes create high friction loss, forcing the pump to work much harder to push water through. This wastes energy. | Use a larger diameter pipe than the pump outlet suggests, especially for long pipe runs. This dramatically reduces friction. |

| 6. Water Quality | Water with a lot of sand, silt, or abrasive material can wear down pump impellers quickly, reducing efficiency. | Use an appropriate intake screen or filter. For very abrasive wells, select a pump specifically designed for those conditions. |

| 7. Electrical Wiring | Undersized wires or long wire runs cause voltage drop, meaning less power reaches the inverter and motor. | Use the correct gauge wire for the distance between the panels and the inverter, as specified in the installation manual. |

A Story of Simple Fixes

I once consulted on a project in Africa where a community was unhappy with their new solar well pump. The flow was a trickle. They had a great pump and inverter from another brand, so the hardware was fine. I flew in and walked the site. The first thing I noticed was the solar panels were laid almost flat on the ground. The second was that they used a very long run of thin, flexible pipe to get the water to the village tank. The Total Dynamic Head from friction alone was huge. We spent a day remounting the panels at the correct 30-degree angle and replacing the narrow pipe with a larger, rigid PVC pipe. The next morning, the water flow was three times stronger. The pump was the same. The sun was the same. We just optimized the external factors, unleashing the true efficiency of their solar water pump.

Conclusion

Maximizing solar pump efficiency is simple. It's about combining a high-efficiency motor and a smart inverter with a well-planned installation that respects the power of its environment.