Struggling with high fuel bills for your industrial pumps?

The initial cost feels high, but solar pumps often prove cheaper than diesel pumps over their lifespan due to zero fuel costs and minimal maintenance. This makes them a smarter long-term investment.

Choosing the right pump system is a major financial decision for any industrial operation.

It impacts not just your initial budget but your operational expenses for years to come.

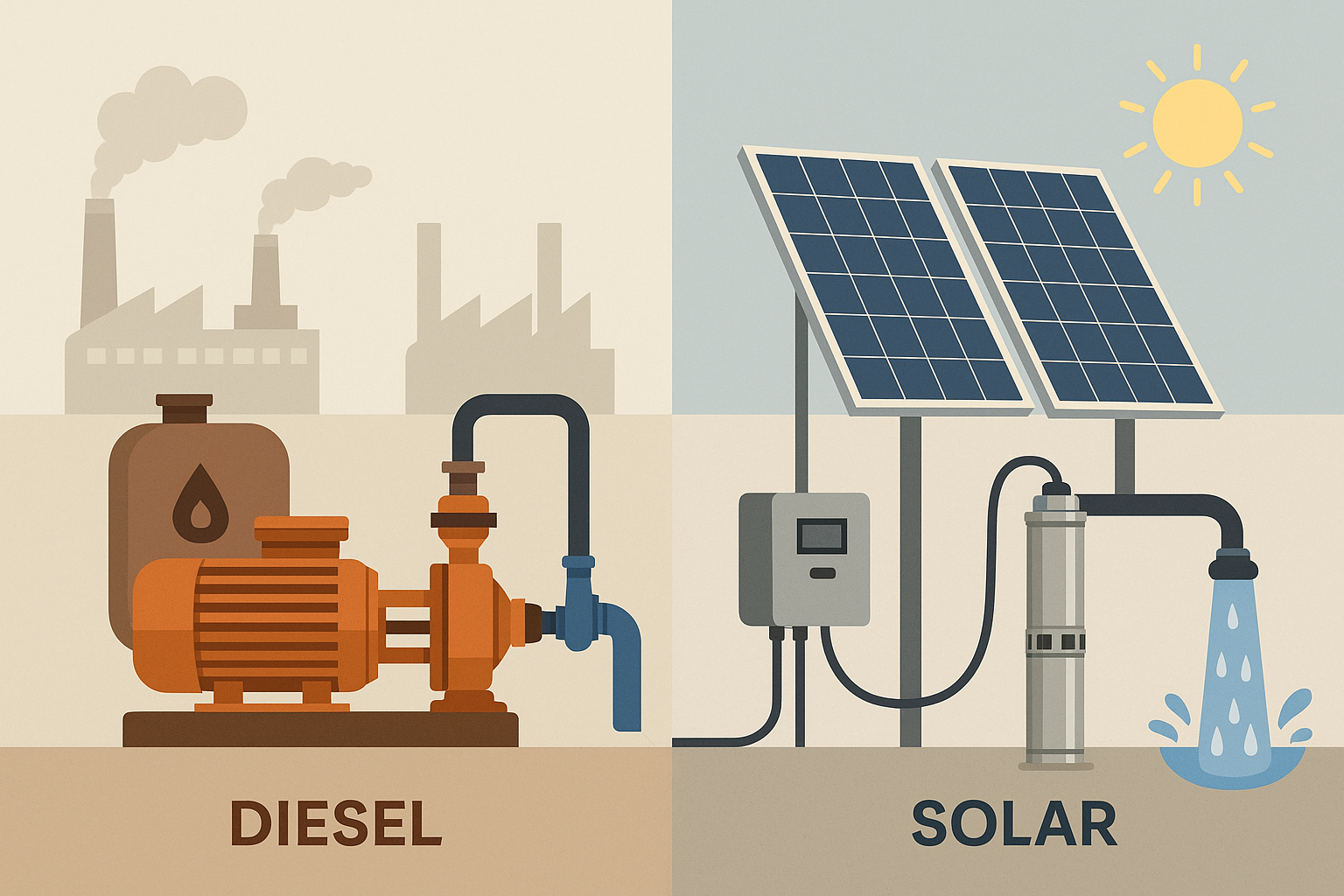

Diesel pumps have long been the traditional choice, known for their raw power.

However, rising fuel prices and environmental concerns are pushing many to look for alternatives.

Solar pumps present a modern, sustainable solution.

But how do they truly stack up when you analyze every single cost?

This guide will break down the costs, revealing the most financially sound choice for your industrial needs.

We will look beyond the price tag to compare everything from fuel and maintenance to lifespan and overall return on investment.

Initial Investment: Unpacking the Upfront Costs

Your initial budget is tight.

A high upfront cost for a new pump system can seem impossible to approve.

While diesel pumps have a lower initial purchase price, solar pumps offer a faster return on investment.

The higher upfront cost of a solar system is offset by eliminating fuel expenses and reducing maintenance needs, making it a sound long-term financial decision.

When evaluating the initial investment, it's crucial to look at the complete system cost, not just the pump unit itself.

This provides a clearer picture of the capital required for each option.

A detailed breakdown reveals why solar systems often carry a higher initial price tag.

The Diesel Pump Setup

A diesel pump system seems straightforward at first.

You purchase the engine and the pump.

However, several other components are essential for a functional industrial setup.

- The Engine and Pump: This is the core of the cost. The price varies based on horsepower and flow rate.

- Fuel Storage Tank: Industrial operations require a large, secure fuel tank. This adds a significant cost.

- Foundation and Housing: Diesel engines are loud and produce vibrations. They often require a concrete slab and a protective enclosure.

- Initial Fuel Supply: You must also purchase a substantial amount of diesel to start operations.

The Solar Pump System

A solar pump system has different core components.

The cost is front-loaded into the energy generation and control systems.

- The Pump and Motor: High-efficiency pumps, often using Permanent Magnet Synchronous Motors (PMSM), are used to maximize water output from solar power.

- Solar Panels (PV Array): This is the largest portion of the upfront cost. The number of panels depends on the pump's power requirement and daily operational hours.

- Mounting Racks: A sturdy mounting system is needed to secure the panels, angled for optimal sun exposure.

- Pump Inverter/Controller: This crucial device manages the power from the panels. It often includes advanced features like Maximum Power Point Tracking (MPPT) to optimize performance throughout the day.

- Wiring and Safety Components: This includes cables, fuses, and disconnect switches to ensure a safe and efficient installation.

A Cost Component Comparison

A side-by-side comparison helps illustrate the differences in capital expenditure.

| Component | Diesel Pump System | Solar Pump System |

|---|---|---|

| Primary Unit | Engine & Pump | Pump & Motor |

| Energy Source | Fuel Storage Tank | Solar Panel Array |

| Infrastructure | Concrete Pad, Housing | Panel Mounting Racks |

| Control System | Basic Throttle/Starter | Advanced Inverter/MPPT Controller |

| Initial "Fuel" | Full Tank of Diesel | None (Sunlight is free) |

While the diesel system's components are individually cheaper, the solar system's cost is almost entirely a one-time investment in long-lasting infrastructure.

The diesel system, by contrast, requires a constant reinvestment in fuel, which is an operational cost we will explore next.

Operational Costs: The True Price of Power

Fuel prices are unpredictable and always rising.

This volatility makes it impossible to budget accurately for your pump's operational costs.

Solar pumps have almost zero operational costs.

They use free energy from the sun.

This eliminates the single largest and most unpredictable expense associated with diesel pumps: the constant need for fuel.

Operational expenditure, or OpEx, is where the financial comparison between solar and diesel pumps dramatically shifts.

A pump that is cheap to buy can become incredibly expensive to run over its lifetime.

Here, we will dissect the day-to-day and month-to-month costs that truly define the economic efficiency of each system.

The Unrelenting Cost of Diesel

The primary operational cost for a diesel pump is fuel.

This is a variable expense that is subject to market fluctuations, supply chain disruptions, and regional pricing.

For an industrial application running several hours a day, this cost adds up quickly.

Consider a pump running for 8 hours daily.

It can consume a significant amount of diesel fuel.

The annual fuel cost alone can often exceed the initial purchase price of the diesel pump itself.

Beyond fuel, you must also factor in the cost of labor.

Someone must transport the fuel to the pump's location.

This is especially costly in remote agricultural or mining sites.

An operator is also needed to start, stop, and monitor the engine regularly.

The Simplicity of Solar Operations

Solar pump systems have a starkly different operational cost profile.

Their primary energy source, sunlight, is free.

Once the system is installed, there are no ongoing fuel bills to pay.

This immediately removes the largest and most volatile operational expense.

The systems are designed for automation.

A solar pump controller automatically starts the pump when there is sufficient sunlight and stops it when it's dark.

This eliminates the need for a dedicated daily operator.

The simplicity of the system means there are very few moving parts to manage on a daily basis, reducing the need for constant oversight.

Calculating Long-Term OpEx

To truly understand the difference, let's look at a simplified 5-year operational cost projection.

We will exclude maintenance for this section.

| Cost Factor | Diesel Pump System (5-Year Estimate) | Solar Pump System (5-Year Estimate) |

|---|---|---|

| Fuel Cost | Varies, but potentially $20,000 - $100,000+ | $0 |

| Labor (Fueling/Operation) | Varies, but potentially $5,000 - $25,000+ | $0 |

| Electricity (for grid-tied) | N/A | N/A (Off-grid) |

| Total Estimated OpEx | High and Variable | Essentially Zero |

This table makes the financial argument for solar incredibly compelling.

The money saved on fuel and labor directly contributes to a rapid return on the initial investment.

Any business owner or engineer focused on cost control will see the clear advantage of a system with predictable, near-zero running costs.

Maintenance and Lifespan: A Long-Term View

Your diesel pump is down again.

Production stops, costs mount, and finding a qualified mechanic for remote repairs is a nightmare.

Solar pumps require minimal maintenance due to fewer moving parts.

Brushless DC motors and durable panels can operate for decades with simple cleaning, ensuring reliable performance and drastically reducing downtime and repair costs compared to complex diesel engines.

The total cost of a system isn't just about purchase price and fuel.

Maintenance requirements and the expected lifespan of the equipment are critical financial factors.

A system that constantly needs repairs or needs to be replaced frequently is not a cost-effective solution.

Let's compare the long-term durability and service needs of both diesel and solar pump systems.

The High-Maintenance Nature of Diesel Engines

Diesel engines are complex machines.

They have many moving parts that are subject to intense heat, friction, and vibration.

This complexity leads to a demanding and costly maintenance schedule.

Common Diesel Maintenance Tasks

- Regular Oil Changes: Just like a car, the engine oil must be checked and changed frequently.

- Filter Replacements: Fuel filters, oil filters, and air filters need regular replacement to prevent damage.

- Coolant System Checks: The radiator and coolant levels must be maintained to prevent overheating.

- Belt and Hose Inspections: These components can crack and fail, leading to major engine damage.

- Engine Overhauls: After a certain number of operating hours, a diesel engine requires a major overhaul, which is a very expensive and time-consuming process.

These tasks require skilled technicians and a steady supply of spare parts.

Downtime during maintenance means a complete halt in water pumping, which can be disastrous for agriculture or industrial processes.

The average lifespan of a diesel pump, with rigorous maintenance, is typically around 15,000 to 30,000 operating hours before a major overhaul or replacement is needed.

The Durability and Low Maintenance of Solar Systems

Solar pump systems are characterized by their mechanical simplicity.

This design philosophy directly translates to enhanced reliability and minimal maintenance needs.

Key Solar System Components and Their Lifespan

- Solar Panels: The panels themselves have no moving parts. They are incredibly durable and resistant to harsh weather. Most manufacturers offer a performance warranty of 20-25 years. The only required maintenance is occasional cleaning to remove dust or debris that might block sunlight.

- Brushless DC Motor: Many modern solar pumps use brushless DC motors. Unlike diesel engines, these motors have very few moving parts. There are no brushes or commutators to wear out. This results in a much longer lifespan and virtually no internal maintenance.

- Pump End: The "wet end" of the pump is similar to any other pump and will require occasional seal or impeller checks, but this is standard for both system types.

- Inverter/Controller: The electronic controller is a solid-state device with no moving parts. It is housed in a protected enclosure and is designed to last for many years without intervention.

The resulting maintenance schedule for a solar pump is incredibly light.

| Maintenance Task | Typical Frequency (Diesel) | Typical Frequency (Solar) |

|---|---|---|

| Major Service | Every 250-500 hours | Annually (Visual Inspection) |

| Fluid Changes | Frequent | None |

| Filter Changes | Frequent | None |

| Component Cleaning | Infrequent (Engine) | Annually (Panel Cleaning) |

| Major Overhaul | 15,000-30,000 hours | Not applicable to motor/panels |

The lifespan of the core components of a solar system (20+ years for panels) far exceeds that of a diesel engine.

This longevity, combined with minimal downtime and low maintenance costs, makes it a more reliable and financially stable asset in the long run.

Performance and Reliability in Industrial Settings

Your water needs are critical.

You can't afford a pump that fails during peak season or can't handle the harsh conditions of your remote site.

Solar pumps provide consistent, automated performance.

They operate reliably in remote, off-grid locations without needing constant supervision or fuel supply logistics.

Modern systems even pump water under overcast skies, ensuring dependable water flow when you need it most.

Performance in an industrial context means more than just a high flow rate.

It means reliability, consistency, and the ability to operate under challenging conditions with minimal human intervention.

While diesel pumps are known for their raw power, solar pumps offer a more intelligent and resilient performance profile that is often better suited for modern industrial and agricultural needs.

Diesel Pump Performance: Power with a Catch

Diesel pumps deliver high power on demand.

You can run them at full capacity, 24/7, as long as you can supply them with fuel.

This makes them suitable for emergency dewatering or applications requiring a constant, high-pressure flow that cannot be interrupted.

However, this performance comes with significant drawbacks.

- Dependency on Fuel: Performance is 100% dependent on a continuous fuel supply chain. Any disruption stops operations immediately.

- Manual Operation: They require manual starting and stopping. This makes them less adaptable to automated systems.

- Inconsistent Efficiency: Diesel engines are most efficient at a specific RPM range. Running them at lower speeds for reduced flow is highly inefficient and can cause premature wear.

- Environmental Sensitivity: They can struggle in very high altitudes due to thinner air or in freezing temperatures without special additives.

Solar Pump Performance: Smart and Adaptable

Solar pumps are designed for a different kind of performance: smart, automated, and efficient.

Modern solar pump inverters with MPPT technology are key to this performance.

How MPPT Maximizes Performance

The controller constantly analyzes the power output from the solar panels.

It adjusts the pump's speed and load to extract the maximum possible power, even in low-light conditions like cloudy or overcast days.

This means the pump doesn't just stop when a cloud passes over.

Instead, it intelligently slows down, continuing to pump water efficiently with the available energy.

This leads to a longer pumping day and more total water moved.

Other Performance Advantages

- Autonomous Operation: The system manages itself. It starts when the sun is up and stops at night. This "set it and forget it" reliability is a huge advantage in remote locations.

- Grid Independence: Solar pumps are completely free from grid failures or fuel shortages, making them exceptionally reliable for critical water supplies.

- Modular Power: If water needs increase, you can often add more solar panels to the existing array to boost performance, offering scalability that diesel pumps lack.

- Consistent Flow: While the flow rate varies with sunlight intensity, it is predictable. For applications like irrigation or filling reservoirs, this steady daily accumulation of water is often more beneficial than short bursts of high-volume pumping.

The reliability of a solar pump comes from its simplicity and independence.

There are no supply chains to manage and no complex engines to fail, providing peace of mind and a truly dependable water source.

Total Cost of Ownership (TCO): The Final Verdict

Making a major purchase based on the sticker price alone is a mistake.

This ignores hidden costs that can cripple your budget down the line.

Solar pumps have a higher initial cost but a significantly lower Total Cost of Ownership (TCO).

When you factor in fuel, maintenance, labor, and lifespan over 5-10 years, the solar option is almost always the more economical choice for industrial use.

Total Cost of Ownership (TCO) is the most important metric for any industrial equipment investment.

It provides a complete financial picture by combining the initial capital expenditure (CapEx) with all ongoing operational expenditures (OpEx) over the asset's lifetime.

This is the ultimate measure of which pump system is truly more cost-effective.

Let's synthesize all the factors we've discussed into a clear TCO comparison.

Components of TCO Calculation

To calculate TCO, we must consider every cost associated with each pump type.

- Initial Purchase & Installation (CapEx): The complete upfront cost of the system.

- Energy Costs (OpEx): The cost of diesel fuel vs. the $0 cost of sunlight.

- Maintenance & Repair Costs (OpEx): Parts, labor, and service contracts.

- Labor Costs (OpEx): Time spent on refueling, daily operation, and monitoring.

- Replacement Costs (CapEx): The cost of major overhauls or full system replacement at the end of its lifespan.

A Simplified 10-Year TCO Scenario

Let's create a hypothetical scenario for a medium-sized industrial pump running an average of 8 hours per day.

These numbers are illustrative examples to show the cost dynamics.

| Cost Category (10-Year Period) | Diesel Pump System Example | Solar Pump System Example |

|---|---|---|

| 1. Initial Investment | $15,000 | $30,000 |

| 2. Fuel Costs | $80,000 (at $10,000/year, volatile) | $0 |

| 3. Maintenance & Parts | $15,000 (oil, filters, repairs) | $2,000 (inspections, minor parts) |

| 4. Labor (Refueling/Ops) | $10,000 | $0 |

| 5. Major Overhaul/Replacement | $10,000 (at least one major overhaul) | $0 (panels/motor within lifespan) |

| ESTIMATED 10-YEAR TCO | $130,000 | $32,000 |

The Inescapable Conclusion

The TCO analysis provides a clear and decisive winner.

Even though the solar pump system required double the initial investment, its total cost over a decade was approximately 75% less than the diesel pump.

The savings on fuel alone far surpassed the initial price difference within the first few years.

This is what financial experts refer to as the payback period.

For solar pumps, the payback period—the time it takes for the savings to equal the initial investment—is often just 2 to 4 years.

After that point, the system generates a positive return on investment for the rest of its 20+ year lifespan.

For any business focused on long-term profitability and predictable budgeting, the TCO model proves that solar pumps are not just an environmental choice, but a superior financial one.

Environmental and Regulatory Factors: The Hidden Costs

Ignoring environmental regulations is risky.

Future carbon taxes, noise ordinances, and emissions standards can add unexpected costs or even shut down your operations.

Solar pumps operate silently and produce zero emissions.

This makes them immune to future carbon taxes and compliant with environmental regulations.

This protects your investment from unforeseen costs and enhances your company's reputation as a sustainable enterprise.

In today's world, the cost of industrial equipment extends beyond direct financial outlays.

Environmental and regulatory factors are introducing new "hidden costs" for pollutive technologies while creating incentives for clean ones.

These considerations can significantly impact the long-term viability and true cost of your pumping solution.

The Growing Burden of Diesel Regulations

Diesel engines are a major source of air and noise pollution.

Governments and regulatory bodies worldwide are implementing stricter rules that directly impact their use.

Potential Regulatory Costs

- Carbon Taxes: Many regions are introducing taxes based on carbon emissions. Every liter of diesel burned will incur an additional cost, directly increasing your operational expenses.

- Emissions Standards: New equipment must meet stringent emissions standards (e.g., Tier 4). These engines are more expensive to buy and maintain. Using older, non-compliant equipment can lead to heavy fines.

- Noise Ordinances: Diesel pumps are extremely loud. Operations near residential or environmentally sensitive areas may face restrictions on operating hours or require expensive soundproofing measures.

- Spill and Contamination Risk: Storing large amounts of diesel fuel on-site carries the risk of soil and water contamination from spills. The cleanup costs and potential fines for such an event can be astronomical.

The Clean and Compliant Advantage of Solar

Solar pump systems neatly avoid all of these regulatory hurdles and associated costs.

They offer a "future-proof" solution that aligns with the global shift towards sustainability.

Key Environmental Benefits

- Zero Emissions: Solar pumps produce no greenhouse gases or harmful pollutants during operation. This eliminates any liability for carbon taxes or emissions-related fines.

- Silent Operation: The systems run virtually silently. This allows for 24-hour operation (if paired with batteries or a reservoir) near sensitive areas without issue.

- No Contamination Risk: There is no fuel or oil to store, transport, or spill. This removes the risk of environmental contamination and its associated liabilities.

- Corporate Social Responsibility (CSR): Using clean energy technology enhances a company's public image. It demonstrates a commitment to sustainability, which can be an advantage when dealing with customers, investors, and regulatory agencies.

As environmental regulations become more stringent, the hidden costs of using diesel will only increase.

Investing in solar is not just about saving money on fuel today; it's about avoiding the compliance costs, taxes, and liabilities of tomorrow.

This proactive approach protects your operation from regulatory risk and positions it as a responsible leader in your industry.

Conclusion

Choosing solar pumps over diesel is a smart financial decision.

The lower total cost of ownership, zero fuel expenses, and minimal maintenance deliver a superior long-term return on investment for any industrial application.

FAQs

1. Are solar water pumps better than diesel?

For long-term cost and reliability, yes. Solar pumps have no fuel costs and less maintenance, making them cheaper over time despite a higher initial price.

2. What is the payback period for a solar water pump?

Typically, the payback period is 2 to 4 years. After this, the savings on fuel and maintenance generate a positive return for the system's entire lifespan.

3. How long do solar water pumps last?

The core components are very durable. Solar panels often have a 20-25 year performance warranty, and brushless motors can last for over a decade with minimal care.

4. What are the disadvantages of solar water pumps?

The main disadvantages are the higher initial investment cost and the fact that their power output is dependent on sunlight, reducing or stopping operation at night.

5. Can a solar pump work at night or on cloudy days?

On cloudy days, performance is reduced but they still pump water. To work at night, they require an additional battery storage system or must pump into a reservoir during the day.

6. How powerful can a solar water pump be?

Modern solar pump systems are highly scalable. They can power large, multi-horsepower pumps suitable for large-scale agricultural irrigation, community water supply, and other industrial applications.

7. Is it difficult to install a solar pump system?

While more components are involved than a diesel pump, installation is straightforward for qualified technicians. It does not require the heavy foundation or fuel infrastructure of a diesel setup.

8. Do solar pumps work in cold climates?

Yes, solar panels can be even more efficient in cold, sunny weather. The system components are designed to withstand a wide range of temperatures and weather conditions.