Is your pump running but no water is coming out?

This frustrating problem can halt your water supply and risk damaging your equipment if left unresolved.

You'll know your pump has an airlock if the motor is running, but you get little to no water flow from your taps.

You may also hear unusual whirring noises, and your pressure gauge will fail to build pressure, often staying at or near zero.

An airlock is essentially a bubble of trapped air in your pump or pipes that stops the flow of water.

Pumps are designed to move liquid, not air.

When a large pocket of air gets stuck, the pump's mechanism can't create the suction needed to pull more water from your source.

This not only stops your water supply but also forces the pump to run without the cooling and lubrication that water provides, a condition that can lead to rapid overheating and severe mechanical damage.

Understanding the specific signs and how they relate to your pump type is the first step toward fixing the problem safely.

The Telltale Signs: Recognizing an Airlock in Your System

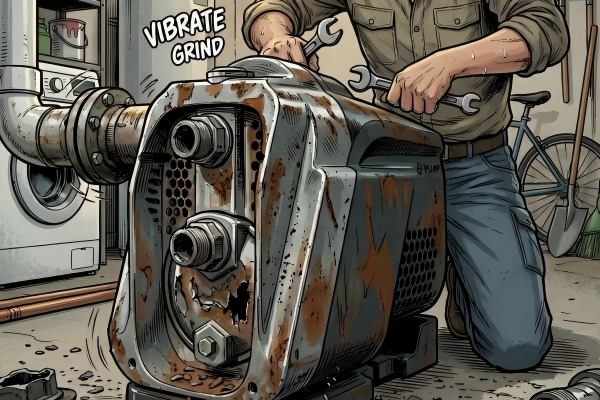

Are strange noises coming from your pump house?

Is your water spluttering from the faucet?

These confusing symptoms can point directly to a stubborn pocket of air disrupting your entire system.

The primary signs of an airlock are a running motor with no water output, sputtering faucets, and a pressure gauge that refuses to build pressure.

Unusual high-pitched whirring or humming sounds from the pump are also classic indicators that it is spinning freely without moving water.

Identifying an airlock correctly is crucial because its symptoms can sometimes mimic other serious issues, like a burnt-out motor or a well that has run dry.

However, an airlock presents a unique combination of audible and visual clues.

By carefully observing your system's behavior, you can confidently diagnose the problem and take the right steps to fix it without causing further damage.

The key is to pay attention to what the pump is doing—and what it's not doing.

Audible and Visual Symptoms

An airlocked pump provides distinct feedback if you know what to look and listen for.

These symptoms arise because the pump's internal components are moving, but they aren't moving the water they were designed for.

-

Distinct Pump Noise: An airlocked pump often sounds different. Instead of the typical loaded sound of moving water, you'll hear a higher-pitched, unloaded whirring or humming. This is the sound of the motor and impeller spinning freely in air, which offers much less resistance than water. This lack of load can cause the motor to run at a slightly higher RPM.

-

No Water or Sputtering Flow: This is the most obvious sign. You turn on a tap, the pump kicks on as expected, but nothing comes out. In some cases, you might get an initial spurt of water followed by air, or a weak, sputtering stream as small pockets of water are pushed through the trapped air.

-

Pressure Gauge Reading: Your system's pressure gauge is a vital diagnostic tool. In a normal cycle, the gauge will climb steadily as the pump fills the pressure tank. With an airlock, the gauge will remain at or near zero, or it might flutter erratically without ever building significant pressure.

Common Causes of an Airlock

Airlocks don't happen randomly.

They are almost always the result of a specific event that allowed air to enter the system.

Common triggers include:

-

Recent Maintenance or Installation: Any time the system is opened, such as during a pump replacement or pipe repair, air will enter. If this air isn't properly bled or purged upon restart, an airlock is highly likely.

-

Well Water Level Dropping: If the water level in your well drops below the pump's intake, the pump will draw in air instead of water. This is a common issue during droughts or in wells with slow recovery rates.

-

Leaks on the Suction Side: For pumps that are not submerged (like jet pumps), even a tiny pinhole leak in the suction pipe can allow air to be drawn into the system continuously, leading to a persistent airlock.

Modern systems with high-efficiency BLDC permanent magnet motors are often paired with intelligent controllers.

These controllers can sometimes help in diagnosis, as the change in motor load from an airlock may trigger a "dry run" or "over-speed" error code, shutting the pump down to prevent damage.

Airlock Susceptibility: How Pump Type Plays a Role

Does your pump seem prone to airlocks after every minor service?

The design of your pump has a huge impact on how it handles air, and understanding this can prevent future frustration.

Centrifugal pumps, such as plastic or stainless steel impeller models, are extremely susceptible to airlock because their impellers cannot compress air to create suction.

Positive displacement pumps, like screw pumps, can handle some air but may still fail to operate if a large air pocket is present.

The fundamental design of a water pump dictates its ability to move fluid and, crucially, its inability to move gas effectively.

Different pump technologies use different mechanical principles to generate flow.

This means that while all pumps can be airlocked, some are far more sensitive to trapped air than others.

Knowing which type you have is crucial for both preventing and resolving an airlock.

Centrifugal Impeller Pumps: High Sensitivity to Air

This is the most common pump design for high-flow applications.

Both Solar Plastic Impeller Pumps and Solar Stainless Steel Impeller Pumps fall into this category.

They work by using a rapidly spinning impeller to throw water outward through centrifugal force, creating a low-pressure area at the center (the "eye") that draws in more water.

- The Problem with Air: This process relies entirely on the presence of a non-compressible fluid—water. When the impeller eye is filled with air, the spinning impeller just whips the air around. Because air is compressible, the impeller cannot create the necessary low-pressure zone to pull water into the pump. The pump is effectively "vapor locked" and will not move any water until the air is removed and the casing is filled with water again (a process called priming).

- Application Relevance: For farm irrigation or ranch water systems that use these high-flow pumps, losing prime due to an airlock can be critical, halting water supply to crops or livestock. The lightweight nature of the plastic impeller pump makes it easy to install, but proper priming is essential. The corrosion resistance of the stainless steel model is vital in acidic water, but its hydraulic function remains just as vulnerable to air.

Positive Displacement Screw Pumps: Better, But Not Immune

A Solar Screw Pump works on a completely different principle.

It's a type of positive displacement pump, specifically a progressing cavity pump.

It uses a helical stainless steel rotor spinning inside a rubber stator.

This action creates sealed cavities of water that are "pushed" up the pipe.

- Handling Air: This design is naturally better at handling some air. It can often push small bubbles and pockets of air through the system along with the water. Because it physically pushes trapped volumes, it can sometimes self-prime by pushing the air out until it reaches water.

- The Limitation: However, a screw pump is not an air compressor. If it ingests a large, continuous volume of air (for example, if the well level drops below the intake), it will stop moving water. The rotor will still spin, but without water to fill the cavities, no pressure is built. Running a screw pump dry is particularly damaging, as it can quickly destroy the rubber stator due to friction and heat. These pumps are ideal for deep wells where high head is needed, but ensuring the water level is stable is paramount.

The table below contrasts the airlock characteristics of these common pump types.

| Pump Type | Principle of Operation | Airlock Susceptibility | Self-Priming Ability | Common Application |

|---|---|---|---|---|

| Impeller Pump | Centrifugal Force | Very High | None (Requires priming) | Farm Irrigation, High-Flow |

| Screw Pump | Positive Displacement | Moderate | Limited (Can handle some air) | Deep Well, High-Head |

The Synergy of Motor and Controller in Fault Detection

Your pump is a smart system, not just a simple motor.

The brain behind your pump can be your best ally in diagnosing problems like an airlock before serious damage occurs.

A high-efficiency BLDC motor paired with an intelligent MPPT controller can detect the abnormal load conditions caused by an airlock.

The controller may register a "dry run" or "overcurrent" fault and shut the pump down, protecting the motor from catastrophic failure.

At the heart of every modern solar water pump is a synergy between advanced hardware and intelligent software.

The BLDC Permanent Magnet Motor is the muscle, offering efficiencies over 90% and powerful torque in a compact size.

This motor is significantly more efficient than older AC or brushed DC motors, meaning it converts more of your valuable solar energy directly into water flow.

However, the true advantage of this system lies in the intelligent controller that acts as its brain.

How Smart Controllers Detect Anomalies

An airlock creates a specific electrical signature that a smart controller can recognize.

When a pump is moving water, the motor is under a consistent, heavy load.

When it's airlocked, the motor is spinning with almost no resistance.

This change is immediately detectable.

-

Dry Run Protection: The controller monitors the motor's power consumption (watts) and speed (RPM). When airlocked, the power drawn drops significantly while the RPM may increase. The controller's algorithm recognizes this signature as a "dry run" condition. After a set period, it will typically shut the motor down and display an error code. This feature is perhaps the single most important protection against burnout from an airlock or a dry well.

-

Current and Load Monitoring: The controller continuously analyzes the electrical current flowing to the motor. The current required to spin an impeller in air is much lower than what's needed to pump a column of water hundreds of feet high. This drop in current is a clear red flag that the pump is not primed or has lost its water source.

The Value of an Integrated System

This intelligent fault detection elevates a water pump from a simple appliance to a self-monitoring system.

It provides a crucial layer of protection that was absent in older, less sophisticated pump setups.

This is a powerful value proposition for distributors and end-users alike.

For a cattle rancher in Australia using a solar stainless steel impeller pump in mildly corrosive borehole water, this protection is invaluable.

An unexpected drop in the water table could airlock the pump.

Without a smart controller, the pump might run for hours, overheat, and fail, leaving livestock without water and the owner with a costly replacement.

With the integrated BLDC motor and MPPT controller, the system would detect the dry run within minutes, shut itself down, and preserve the equipment until the issue can be resolved.

This proactive protection is a core feature of the entire competitive product portfolio, from the high-head screw pump to the high-flow impeller pumps.

It leverages the efficiency of the motor and the intelligence of the controller to provide not just water, but reliability and peace of mind.

Conclusion

An airlocked pump shows clear signs: a running motor with no water, sputtering flow, and no pressure.

Identifying the pump type helps resolve it, ensuring your system's longevity and reliability.

Frequently Asked Questions

How do you get an airlock out of a water pump?

Often, you can bleed the air out through a dedicated prime plug or by slightly loosening a fitting on the output side until water flows steadily, then retightening it.

What causes a water pump to get airlocked?

Common causes include running the pump dry, a low water level in the well, or leaks in the suction line that allow air to be drawn into the system.

Can an airlock damage a water pump?

Yes, an airlock can cause a pump to run dry, leading to overheating and severe damage to seals, impellers, or stators due to lack of lubrication and cooling.

Will an airlock clear itself?

Rarely. While a very small bubble might be pushed through, a significant airlock in a centrifugal pump will not clear on its own and requires manual intervention to bleed the air.

How do I prime my well pump?

To prime a pump, turn off the power, remove the prime plug, and slowly fill the pump casing and suction pipe with water until it's completely full, then replace the plug.

Does turning a faucet on and off get rid of an airlock?

This method, sometimes called "purging," can occasionally work for very minor airlocks in home plumbing, but it is generally ineffective for an airlocked pump itself.

Why do I suddenly have air in my water lines?

Sudden air can be caused by recent plumbing work, a main water line break in your area, or a problem at your wellhead, such as a failing check valve or a drop in water level.

Can a bad foot valve cause an airlock?

Yes. A faulty foot valve at the bottom of the pipe in the well can leak, allowing the water column to drain back and air to enter the system, causing the pump to lose its prime.