Your pump is the heart of your water system.

But if the well runs dry, the pump can keep running silently.

This can lead to a sudden, catastrophic, and expensive failure.

No, a submersible pump absolutely cannot run without water.

Running "dry" for even a few minutes will cause rapid overheating and catastrophic failure of the motor and seals. Water is essential for both cooling and lubrication, and without it, the pump will destroy itself.

This isn't a minor issue; it is the single fastest way to destroy a perfectly good pump.

Every submersible pump, regardless of its price or quality, is designed with the explicit assumption that it will be fully submerged during operation.

The water it is sitting in is not just something to be moved.

It is an integral and life-sustaining part of the pump's operating environment.

Understanding precisely what happens inside a pump when it's starved of water reveals why this situation is so critical.

The damage is not a gradual wear-and-tear process.

It is a rapid, cascading failure where one component's destruction quickly leads to the next.

Let's explore the physics behind this failure and, more importantly, the modern technological solutions that prevent this disaster from ever happening.

Why Dry Running Destroys a Submersible Pump

Your pump suddenly stopped working.

You assumed it was a quality unit built to last.

But it failed because the well level dropped, and the pump burned itself out.

Dry running causes catastrophic failure because water serves two vital functions: cooling and lubrication.

Without water to dissipate heat and lubricate moving parts, the motor overheats and the mechanical seals seize, leading to irreversible damage within minutes.

A submersible pump is a powerful machine operating in a sealed environment.

Its design is a masterclass in efficiency, but it has one fundamental dependency: water.

Removing that single element from the equation starts a chain reaction of self-destruction.

The two main pillars of this failure are heat and friction.

The pump is designed to use the surrounding water to manage both of these forces.

When the water is gone, the pump has no defense.

This is true for every type of pump, from a basic home unit to a high-powered agricultural pump.

Even the most advanced, high-efficiency BLDC motor, which runs cooler than older motor types, cannot survive being run dry.

The principles of thermal dynamics and mechanical friction are unforgiving.

For a distributor like Andrew in Australia, understanding and explaining this concept is crucial for customer satisfaction and avoiding costly warranty claims.

It is not a product flaw; it is a fundamental operating principle of the technology.

The Critical Role of Water as a Coolant

Every electric motor generates heat as a byproduct of its operation.

Even a high-efficiency Brushless DC (BLDC) motor, which can be over 90% efficient, still converts up to 10% of its electrical energy into heat.

In a submersible pump, this heat is generated within a compact, sealed stainless steel tube hundreds of feet underground.

There is nowhere for the heat to go.

The pump's design relies entirely on the cooler, ambient water of the well to act as a giant heat sink.

The water flows constantly over the motor housing, absorbing the heat and carrying it away.

This keeps the motor's internal temperature within a safe operating range.

When the pump runs dry, this cooling mechanism vanishes.

The heat generated by the motor becomes trapped.

The motor's temperature begins to rise rapidly, quickly exceeding the thermal limits of the copper windings and their insulation.

The insulation melts, the windings short-circuit, and the motor burns out.

Lubrication Failure: The Mechanical Breakdown

Beyond cooling the motor, water also serves as the essential lubricant for the pump's most critical moving parts.

Specifically, the mechanical seals and bearings are designed to operate in a wet environment.

-

Mechanical Seals: These seals prevent water from entering the dry, oil-filled motor housing. They typically consist of two ultra-hard, polished rings (often carbon and ceramic) pressed tightly together. A thin film of water between these rings acts as a lubricant and a coolant, allowing them to spin against each other at high RPMs with minimal friction and wear.

-

Bearings: The pump shaft is supported by several bearings that allow it to spin freely. These bearings also rely on the water to help dissipate the heat generated by friction.

When a pump runs dry, the lubricating film of water in the mechanical seal instantly disappears.

The two hard seal faces begin grinding directly against each other.

The friction is immense, generating intense, localized heat far greater than the heat from the motor itself.

The seal surfaces superheat, crack, and disintegrate.

Simultaneously, the bearings overheat, expand, and seize.

The entire mechanical system grinds to a halt in a catastrophic failure.

Dry Run vs. Normal Operation

| Component | Normal Operation (Wet) | Dry-Run Operation (No Water) | Consequence of Dry Running |

|---|---|---|---|

| Motor Windings | Cooled by surrounding water. | Heat is trapped, temperature rises rapidly. | Motor Burnout (Melted insulation, short circuit) |

| Mechanical Seal | Lubricated and cooled by water film. | Extreme friction, intense localized heat. | Seal Destruction (Melting, cracking, water ingress) |

| Bearings | Cooled by surrounding water. | Overheat due to friction. | Bearing Seizure (Shaft lock-up) |

| Impellers | Cooled and hydraulically balanced. | Can overheat and warp (plastic). | Pump End Failure (Reduced performance, seizure) |

This cascading failure, starting with the loss of cooling and lubrication, is why dry running is not a minor operational issue—it is a death sentence for a submersible pump.

The Anatomy of a Dry-Run Failure: What Breaks First?

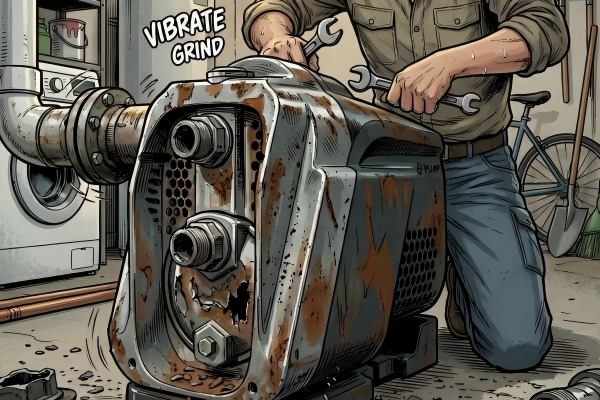

You hear a high-pitched squeal from your well equipment.

You hope it's nothing, but the sound is your pump screaming for water.

Ignoring it means a silent, expensive failure is imminent.

The mechanical seal is almost always the first component to fail during a dry run.

The extreme friction generates intense heat, melting or shattering the seal faces in under a minute. This allows water to flood the motor, causing a terminal electrical failure.

The destruction of a pump during a dry run follows a brutally quick and predictable sequence.

While the motor is slowly overheating, a much faster and more violent failure is happening at the mechanical seal.

This small, precise component becomes ground zero for the pump's demise.

Understanding this sequence of failure helps to appreciate why even a few moments of dry running can be fatal.

The damage is not linear; it is an exponential cascade of thermal and mechanical destruction.

From the first moment the water level drops below the pump's intake, a countdown to total failure begins.

The materials used in the pump, such as plastic impellers versus stainless steel, can influence which secondary failures occur, but the initial point of failure is nearly always the same.

Stage 1: The Mechanical Seal Meltdown

The mechanical seal is the pump's most vulnerable point in a dry-run scenario.

It is designed to handle high pressure from the outside and high rotational speed from the inside, but only with water present.

Without the lubricating and cooling film of water, the two hard faces of the seal (e.g., carbon and ceramic) are grinding against each other at thousands of RPMs.

The resulting friction generates heat almost instantly.

The temperature at the seal interface can skyrocket to several hundred degrees Celsius within seconds.

This extreme temperature does two things:

- It can cause the seal faces to warp or crack from thermal shock.

- It melts the elastomer (rubber) bellows or O-rings that hold the seal faces in position and provide elasticity.

Once the seal is compromised, the failure accelerates.

The next time water returns to the well and the pump is turned on, water will be forced past the broken seal and directly into the motor housing, which is supposed to remain perfectly dry.

Stage 2: Pump End Damage (Impellers and Diffusers)

Simultaneously, the "wet end" of the pump is also suffering.

This is the part of the pump containing the impellers and diffusers that actually move the water.

The effect of dry running here depends on the material.

-

Solar Plastic Impeller Pumps: These use durable, wear-resistant plastic impellers. While excellent for handling fine sand, the plastic has a lower melting point than metal. The heat from friction and the nearby overheating motor can cause the impellers to warp or even melt. The close tolerances between the spinning impeller and the stationary diffuser are lost, causing them to bind and seize.

-

Solar Stainless Steel Impeller Pumps: These use robust SS304 impellers. While they will not melt, the intense heat can cause them to expand. This thermal expansion can be enough to cause the stainless steel impeller to scrape against the pump housing or diffusers, leading to galling (a form of wear caused by adhesion between sliding surfaces) and eventual seizure.

-

Solar Screw Pumps: In a screw pump, the stainless steel screw rotates inside a rubber stator. Running dry creates massive friction between the screw and the rubber, which can tear the stator or cause it to overheat and melt, destroying the pump's ability to move water.

Stage 3: Catastrophic Motor Burnout

This is the final, irreversible stage of failure.

It can happen in two ways.

-

Failure by Water Ingress: This is the most common outcome. Following the destruction of the mechanical seal (Stage 1), water floods the motor housing. This causes an immediate and massive electrical short circuit. The motor windings are instantly fried. This is often the cause of a tripped circuit breaker that will not reset.

-

Failure by Pure Overheating: Even if the mechanical seal somehow survived, the motor a high-efficiency BLDC permanent magnet motor cannot dissipate its own heat without the cooling effect of the surrounding water. The temperature will continue to climb until the enamel insulation on the copper windings burns off. This causes the windings to short against each other, and the motor fails.

This entire catastrophic sequence, from a healthy pump to a piece of scrap metal, can happen in less than five minutes of dry-run operation.

The Solution: How Modern Pumps Prevent Dry Running

You worry about your well level dropping during a dry spell.

Checking it manually is impossible.

You need an automatic system that protects your pump investment, giving you total peace of mind.

Modern pumps prevent dry running with intelligent controllers featuring automatic load-monitoring protection.

The controller constantly analyzes the motor's power draw. When the pump runs out of water, the load drops, and the controller instantly shuts it off before any damage can occur.

The destructive power of a dry run is well understood by pump engineers.

Preventing it has been a major focus of pump system design for decades.

Early solutions involved cumbersome and often unreliable float switches or probes installed in the well.

Today, the solution is far more elegant, reliable, and intelligent.

It is built directly into the brain of the pump system: the controller.

This technological leap has transformed dry-run protection from an optional add-on to a standard, built-in feature that makes modern pump systems vastly more durable and reliable.

For an importer or distributor, offering products with this built-in protection is a massive competitive advantage.

It directly addresses a primary cause of pump failure, leading to happier customers and a stronger brand reputation for quality and reliability.

Intelligent Controllers: The Pump's Guardian

The controller of a modern solar water pump does much more than just convert DC power from the panels.

It is a sophisticated computer that continuously monitors and protects the entire system.

The most critical protective function is sensorless dry-run protection.

Here is how it works:

- Establish a Baseline: When the pump is running normally and full of water, the controller measures the amount of electrical power (amperage and wattage) the motor needs to lift that column of water.

- Constant Monitoring: The controller monitors this power draw hundreds of times per second.

- Detect the Anomaly: If the water level drops and the pump begins to suck in air, it is no longer doing the work of lifting a heavy water column. The load on the motor drops significantly. The motor spins more freely, and its power draw plummets.

- Execute Protection: The intelligent controller instantly recognizes this sharp drop in power draw as a dry-run event. It immediately cuts power to the motor, shutting it down safely.

- Smart Restart: The controller will not restart the pump immediately. It will wait for a pre-programmed period (e.g., 30 minutes) to allow the well's water level to recover. It will then attempt a soft restart. If it detects a dry run again, it shuts down and waits again.

This entire process happens automatically, without any human intervention.

It provides foolproof protection against the most common cause of premature pump failure.

The Power of Integrated Technology

This level of protection is a standard feature in high-quality solar pump systems that utilize a BLDC motor paired with an intelligent MPPT (Maximum Power Point Tracking) controller.

The MPPT function is already a sophisticated monitoring system designed to optimize power from the solar panels.

Adding the logic for dry-run protection to this existing hardware is a natural and highly effective evolution of the technology.

| Protection Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Old Method: Float Switches | A physical float switch is wired to the pump controller. When the water level drops, the float drops and opens the circuit. | Simple concept. | Adds another component to install and fail. Wires can be damaged during installation. Unreliable in turbulent water. |

| Modern Method: Sensorless | The intelligent controller analyzes the motor's power draw to detect a dry-run condition. No extra parts in the well. | Extremely reliable. No extra components to fail. Easy installation. Can be fine-tuned via software. | Requires a sophisticated, high-quality controller. |

The Hybrid Advantage: 24/7 Protection

This intelligent protection is not limited to when the pump is running on solar power.

Advanced systems offer a hybrid AC/DC controller.

This allows the pump to be powered by solar panels during the day, and automatically switch to an AC power source (like the grid or a generator) at night or on cloudy days.

Crucially, the intelligent dry-run protection functionality remains active regardless of the power source.

Whether the pump is running on 200V DC from solar panels or 220V AC from the grid, the controller is still monitoring the motor's load.

This ensures the pump is protected from dry running 24 hours a day, 7 days a week, providing a truly worry-free water supply and maximizing the return on your investment in a high-quality pump.

Conclusion

A submersible pump cannot run without water; it leads to rapid self-destruction.

Modern systems with intelligent controllers and automatic dry-run protection make this a problem of the past.

Frequently Asked Questions

How long can a submersible pump run without water before damage?

Damage begins almost instantly. The mechanical seal can be destroyed in under 60 seconds, leading to catastrophic motor failure shortly after. Never operate a submersible pump out of water.

What does a pump sound like when it runs dry?

A pump running dry may produce a high-pitched whining or grinding sound as the bearings and seals are starved of lubrication. However, it can also fail silently.

How do I know if my pump has run dry?

The most obvious sign is a complete loss of water flow. You might also notice sputtering air from the faucet. An intelligent controller will typically show a "dry run" or fault light.

Can a dry-run pump be repaired?

It is technically possible but usually not economical. A dry-run event typically destroys the mechanical seal, bearings, and motor, meaning a full replacement is often cheaper than a complex repair.

Does a well pressure tank protect a pump from running dry?

No. A pressure tank manages pressure and reduces pump cycling but offers no protection against the well itself running out of water. Only specific dry-run protection features can do this.

What is the best way to prevent a pump from running dry?

The best method is to use a pump system with a modern, intelligent controller that has built-in, sensorless dry-run protection based on motor load monitoring.

Is there a type of pump that can run dry?

Some specialized industrial pumps can, but standard submersible water pumps for wells cannot. The fundamental design relies on water for cooling and lubrication.