Is your solar pump acting up?

Worried about sudden breakdowns and the high cost of repairs?

Proper care keeps your solar water pump working well, saving you stress and money.

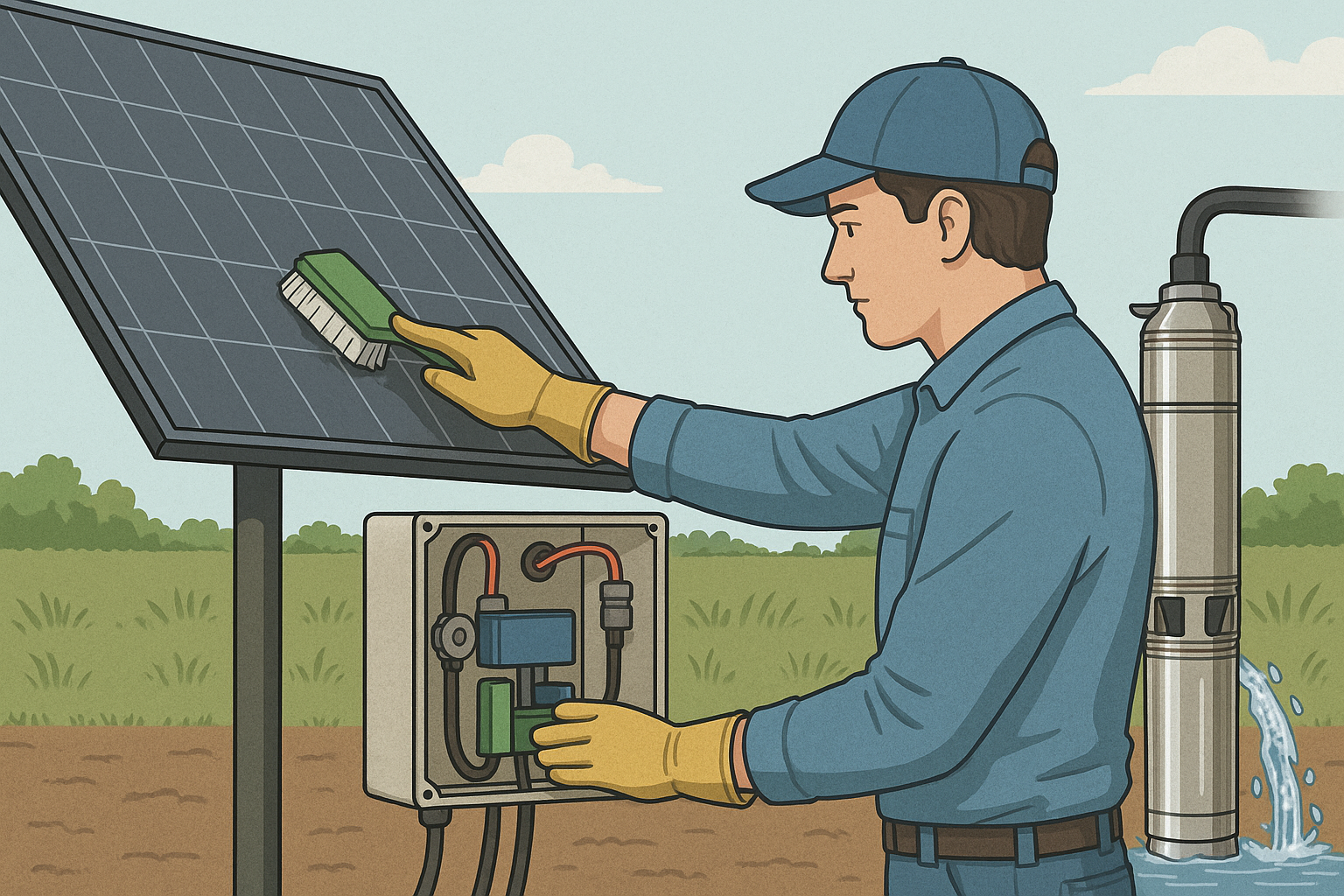

The best way to maintain your solar water pump is through regular inspections and cleaning. This includes checking solar panels for dirt, ensuring all wiring is secure, inspecting the pump for debris, and keeping filters clear. This routine care maximizes efficiency and extends the pump's life.

Keeping your solar water pump in good condition is not too complicated.

However, it does need regular attention.

I've learned a lot about these systems over many years.

My experience comes from both my time in the factory and helping clients setup their own systems.

Let me show you exactly what you need to do.

It's very important to follow these steps to get the most from your investment and ensure reliable water access.

What specific maintenance does a solar water pump system truly require?

Is your system not working like it used to?

Are you unsure what to look at first?

Knowing the main things to check helps avoid big repair bills and keeps your water flowing smoothly.

A solar water pump system needs you to clean the solar panels often. You also need to check the wires, controller, and connections. The pump unit itself must be checked for any blockages. You should also watch the water flow to make sure everything is working right.

To keep your solar water pump system running smoothly, you must look after several key parts.

It's not just the pump; the whole system works together as one.

I remember a client who had performance issues with their pump.

It turned out their solar panels were just incredibly dusty.

This dust was cutting the power output significantly.

Once we cleaned the panels, the pump worked perfectly again.

A complete system check involves more than just the pump itself.

Solar Panel Care

Your solar panels are the power source for the entire system.

If they cannot get enough sun, your pump will not work well.

It might run slowly or not at all.

- Regular Cleaning: Dust, leaves, bird droppings, and other debris can cover the panels. You need to clean them regularly to maintain peak performance. Use clean water and a soft brush or cloth. I usually suggest doing this every few months. If you live in a very dusty area or near trees, you may need to clean them more often.

- Inspection: Check for any cracks, chips, or other damage to the panel surface. Even small cracks can let moisture in and cause problems over time. Also, make sure the mounting frame is secure and not loose.

Wiring and Connections

Loose or damaged wires can cause big problems.

They can reduce the power getting to your pump.

In worst-case scenarios, they can stop the pump from working entirely or create a safety hazard.

- Visual Checks: Look at all the wiring between the panels, the controller, and the pump. Make sure all connections are tight and not corroded. I have seen connections loosen over time due to normal vibrations or weather changes.

- Protection: Ensure all wires are protected from animals that might chew on them. Physical damage from equipment is also a risk. Using a conduit to house the wires is always a good idea for long-term protection.

The Inverter: The System's Brain

The solar pump inverter, or controller, is the central processing unit of your system.

It converts DC power from the panels to AC power for the pump.

It also optimizes performance with features like Maximum Power Point Tracking (MPPT).

Protecting it is critical.

- Proper Location: The inverter must be installed in a well-ventilated, dry, and shaded location. Avoid exposing it to direct sunlight or extreme temperatures, as heat is a primary enemy of electronic components.

- Surge Protection: Lightning strikes can be devastating. Install properly rated surge protectors or lightning arrestors on the inverter’s input and output terminals. This protects it from lightning-induced voltage spikes. Disconnecting the system during severe thunderstorms is also a wise precaution.

- Monitoring: Many modern inverters allow for monitoring. Use a datalogger or monitoring system to track the inverter’s voltage, current, and temperature. Regular monitoring helps you identify potential problems early before they become serious failures.

Pump Unit and Wellhead

The pump itself and the water source also need your attention.

Neglecting them can lead to clogs and serious damage.

- Debris Check: For submersible pumps, ensure the wellhead is properly sealed. This prevents debris, insects, or small animals from falling in and clogging the pump. For surface pumps, make sure the intake area in the water source is always clear.

- Water Quality: The water itself affects the pump. The water pH should ideally be between 6.5 and 8.5. The sand content must not exceed 0.01%. Pumping abrasive or corrosive water will wear out components much faster.

- Water Level: If you're pumping from a well, tank, or pond, always be aware of the water level. Running a pump dry can destroy it very quickly. I always advise clients to install dry-run protection if their system does not already have it.

So, how exactly do you maintain a solar water pump?

Are you ready to get your hands a little dirty?

Not sure exactly what the first step is?

I will guide you through the practical steps for good solar pump maintenance.

To maintain a solar water pump, you should first disconnect it from power for safety. Then, regularly remove and clean its filters. Also, check the impeller and flow valve for any blockages from sand or debris. Finally, reassemble and test it.

Maintaining the pump unit itself is very important for its long life and good performance.

I have seen many pumps fail early simply because this basic cleaning was overlooked.

Here is a general guide that I often share, based on common pump designs.

Remember to always check your pump’s specific manual as well, because the steps can vary between models.

Safety Always Comes First

Before you touch any part of the pump or wiring, your first action must always be to ensure your safety.

Electrical shock is a serious risk.

Always disconnect the pump from its power source.

This usually means shutting off the connection at the solar controller or inverter.

I always double-check that the power is off with a voltmeter before I touch anything.

This simple step prevents any chance of electrical shock or the pump starting up by accident while you are working on it.

A Step-by-Step Cleaning Guide

This detailed cleaning might be needed every few months or up to a year.

It depends entirely on your water quality.

If the water is very gritty or has a lot of minerals, you might need to do it more often.

Here is a table outlining the steps I recommend.

| Step | Action | Why It's Important | My Tip |

|---|---|---|---|

| 1. Safety First | Disconnect the pump from its power source (the solar controller). | Prevents electrical shock or accidental startup. | I always double-check the power is off before I touch anything. |

| 2. Remove & Clean Filter | Remove the filter cover and the foam or mesh filter inside. Clean both thoroughly. | A clogged filter greatly reduces water flow and puts a lot of strain on the pump motor. | Rinse them under clean water. A soft brush can help remove stubborn dirt without causing damage. |

| 3. Check Flow Valve | Inspect and clean the variable flow valve, if your pump has one. | Debris like small stones or leaves can jam the valve, which affects your ability to control the water flow. | After cleaning, make sure the valve moves freely through its full range of motion. |

| 4. Inspect Impeller Access | Check the impeller area for any blockages without full disassembly first. | Small debris like stringy weeds or plastic can often be removed easily from the inlet area. | Sometimes, just clearing this inlet is enough to restore full water flow. Use a pair of pliers to pull out debris. |

| 5. Disassemble & Clean | Carefully take apart the pump body and impeller assembly. Clean all parts. | This removes stubborn grit and scale from the critical moving parts, preventing wear and failure. | Note the order of parts as you take them apart. Taking a photo with your phone has saved me headaches early in my career! |

| 6. Reassemble & Test | Reassemble all parts correctly in the reverse order. Reconnect power and test the pump. | This ensures everything is put back together properly and is working as it should before you rely on it. | Listen carefully for any strange grinding or rattling noises after you turn it back on. This could indicate a problem. |

Prohibited Behaviors to Avoid Damage

To ensure the safety and longevity of your equipment, there are several things you should never do.

These actions can cause immediate and expensive damage.

- Never run the pump directly from the solar panels without a controller or inverter. The controller is essential for managing voltage and current.

- Never run the pump without water (running it dry). This is one of the fastest ways to burn out the motor.

- Never use the pump in a non-clean water environment like sewage or saltwater unless it is specifically designed for that purpose.

- Never use the system if the solar panel is damaged or the wiring insulation is exposed.

- Never hit the pump body with hard objects or pull on the electrical cable to lift or lower the pump. Always use the attached rope.

What are the essential maintenance steps needed for these pumps?

Feeling a bit swamped by all of the details?

Do you need a simple checklist you can follow regularly?

These basic steps make pump care much easier, keeping your system working well for a longer time.

The key steps for pump maintenance are cleaning filters, checking the impeller for clogs, and looking at seals for wear. You must also ensure electrical connections are safe and tight, and regularly check how the whole system is working and sounding during operation.

Beyond the specific disassembly and cleaning I just described, there are ongoing checks.

These checks form the backbone of good pump maintenance.

Think of it like owning a car.

You get regular oil changes, but you also check the tire pressure more often.

I always tell my clients that a little bit of regular attention goes a very long way in preventing major problems.

It's about creating a simple, easy-to-follow routine.

Routine Operational Checks

These are simple things you can do frequently, even daily or weekly, without taking anything apart.

They are your first line of defense in spotting a problem.

- Listen to the Pump: Get familiar with what your pump sounds like when it is running normally. Does it sound the same today? Any new grinding, whining, or rattling sounds can indicate a problem like a failing bearing or debris inside the pump. I once diagnosed a failing bearing just by the high-pitched sound it was making.

- Check Water Flow: Is the output from your pipe or tap strong and consistent? A sudden drop in flow rate or pressure can mean there is a clog somewhere, a leak in the piping, or a problem with the power supply from the panels or controller.

- Inspect for Leaks: Look around the pump body (for surface pumps) and any fittings, pipes, or connections. Check for any signs of water leaks. Even a small drip can lead to bigger issues, waste precious water, and may indicate a failing seal or loose fitting.

Scheduled Deeper Inspections

These checks might be done monthly or quarterly, depending on your system and environment.

They require a little more effort but are critical for long-term health.

- Clean Intake Screens/Filters: As mentioned before, this is one of the most critical tasks. A clogged filter is a very common cause of low performance.

- Check Seals and Gaskets: Look for any signs of wear, cracking, or damage on any visible seals. Seals are what prevent water from getting into the motor or other sensitive electronic parts. Replacing a worn seal is much cheaper than replacing an entire motor.

- Verify Electrical Connections: Always turn off the power first. Then, check that all connections at the pump, controller, and panels are still tight and free of corrosion. Vibration can loosen screw terminals over time.

- Impeller Check: On some pumps, the impeller is easily accessible for a quick inspection. Make sure it can spin freely and is not clogged with stringy material like weeds or plastic bags.

Creating a Maintenance Schedule

A simple schedule can help you stay on track.

Here is a sample schedule you can adapt to your own needs.

| Frequency | Task |

|---|---|

| Daily/Weekly | Listen to the pump's sound. Check for consistent water flow. Visually inspect for any leaks. |

| Monthly | Clean the primary intake screens. Check the controller display for any error codes or unusual readings. |

| Quarterly | Perform a deep cleaning of all filters. Visually inspect seals and gaskets. Check that all electrical connections are tight. |

| Annually | Consider a full pump disassembly for deep cleaning and inspection of the impeller and seals, especially if you have hard or sandy water. |

What is the life expectancy of a solar water pump?

Are you thinking about getting a new solar pump?

Or are you wondering how long your current one will last?

Knowing the typical lifespan and what affects it helps you plan for the future and get the best value.

A solar water pump that is well looked after can last for 10 to 20 years. The solar panels themselves often last even longer, perhaps 20 to 25 years. How well you maintain the entire system, especially the pump, really affects how long it will work.

The lifespan of a solar water pump system is not a single, fixed number.

It depends on several important factors.

But with good care, these systems are very durable and reliable.

I have seen systems that I helped install over a decade ago that are still going strong today with only minor maintenance.

Factors Influencing Lifespan

Many variables can impact how long your pump will last.

- Pump Quality: Higher quality pumps will generally last longer. Those made with stainless steel components or more robust brushless motors are a better investment than cheaper, plastic-bodied pumps. The upfront cost is higher, but it pays off in durability.

- Water Quality: Pumping water that is sandy, gritty, or corrosive will wear out pump components like impellers and seals much faster. If your water source is not clean, good pre-filtering before the pump is essential.

- Operating Conditions: How often does the pump run? Is it sized correctly for the job? An undersized pump that is overworked, or a pump that frequently runs dry, will have a much shorter life.

- Maintenance: This is the big one. Regular cleaning and inspection, as we have discussed in this guide, can significantly extend a pump's life. Neglect is a pump's worst enemy. I have seen pumps fail in just a few years due to a simple lack of cleaning.

- Environment: Extreme temperatures, high humidity, or other harsh weather can also play a role. This is especially true for any exposed components like surface pumps, wiring, or the controller unit.

Typical Component Lifespans

It helps to think about the lifespan of each major part of the system.

- Pump Motor/Wet End: This is the part that typically has the 10-20 year estimate if it is well-maintained. The motor itself might last even longer than the "wet end" parts like seals or impellers. These wear parts can often be replaced to further extend the life of the unit.

- Solar Panels: These are incredibly reliable. They often come with performance warranties of 20 to 25 years. They can continue producing power even longer, though their efficiency might slowly and slightly decrease over many years.

- Controller/Inverter: The electronic controller is a sophisticated device. It can last anywhere from 5 to 15 years, and sometimes more. They are often protected inside a weatherproof enclosure, which helps them last longer. High-quality inverters with good heat management tend to have a longer operational life.

By taking good care of your system, you can maximize its operational life.

This includes replacing wear parts like seals when needed.

It also means ensuring it's not working in overly harsh conditions.

This proactive approach will give you the best return on your investment.

Conclusion

In short, regular checks and consistent cleaning are vital.

This care ensures your solar pump works efficiently for many years, giving you reliable water and peace of mind.

FAQs

How often should solar pump panels be cleaned?

Clean panels every few months, or more in dusty areas.

This ensures maximum power generation for the pump to run effectively.

Can a solar pump run without a battery?

Yes, most systems run directly from panel power during the day.

The controller manages power, so batteries are not always necessary.

What happens if a solar pump runs dry?

Running a pump dry causes it to overheat, which can quickly damage the motor.

Many systems have dry-run protection to prevent this.

Why is my solar pump pressure low?

Low pressure can result from dirty panels, a clogged filter, or a worn impeller.

Start by cleaning the panels and filters.

How do I protect my solar pump from lightning?

Install properly rated surge protectors on the inverter's input and output.

This guards against damaging voltage spikes from lightning strikes.

Can you use any solar panel with a water pump?

No, the panel's voltage and current must match the controller and pump's requirements.

An improper match can lead to poor performance or damage.

What is the main cause of pump failure?

The most common causes are running dry and pumping abrasive sand without proper filtration.

Neglecting basic cleaning and maintenance is also a primary factor.

How deep can a solar pump go?

This depends on the pump model.

Solar deep well pumps can work hundreds of feet deep, while surface pumps are for shallow sources.