Running a new pump only to hear it whine without moving any water is a frustrating and costly problem.

This leads to project delays, wasted man-hours, and potential equipment damage.

Understanding the fundamentals of priming is the first step to ensuring flawless operation every time.

Yes, a standard centrifugal pump must be primed (filled with liquid) before starting.

It cannot move air effectively, and priming is essential to create the suction and pressure needed to pump liquid.

Failure to prime causes dry running, which leads to overheating, cavitation, and serious internal damage.

Knowing the "why" behind this rule is crucial for any technician, engineer, or distributor.

It separates routine maintenance from catastrophic failure.

While the basic principle is simple, the consequences of ignoring it are severe.

But what if technology could make this problem almost obsolete?

Let's explore the core reasons for priming and then uncover how modern, intelligent pumps provide a much smarter solution.

Why Priming Is Necessary

Your pump hums, the motor spins, but no water comes out.

This isn't just an inconvenience; the pump is actively damaging itself with every rotation.

Ignoring this can turn a simple setup issue into a complete pump replacement, costing you time, money, and credibility with your client.

A centrifugal pump works by accelerating liquid, but it is not an air compressor.

The impeller is designed to grip dense liquid, not thin air.

Running without liquid—a condition called "dry running"—causes rapid overheating and friction, destroying critical internal components like seals and bearings.

To truly grasp the importance of priming, we need to look at the physics and the mechanics happening inside the pump casing.

It’s a simple concept with major implications for the pump's health and lifespan.

Understanding what happens at a component level when a pump runs dry highlights why this is a non-negotiable step for standard pumps and why intelligent protection systems are a game-changer.

The Physics: Why Impellers Can't Move Air

A pump's impeller works on a simple principle: it spins rapidly to sling liquid outwards by centrifugal force.

This action creates a low-pressure zone at the center (the "eye" of the impeller), which sucks in more liquid from the suction line.

The entire process depends on one key fact: the fluid being moved has enough mass and density for the impeller to "grip."

Liquid has this density; air does not.

Trying to make an impeller move air is like trying to row a boat with a feather.

There's a lot of motion, but no effective work is being done.

The impeller just spins freely within the air-filled casing, unable to generate the pressure differential needed to draw water up the suction line.

The Devastating Effects of Dry Running

When a pump runs dry, the water that normally cools and lubricates the internal components is absent.

This creates a hostile environment where friction quickly leads to a cascade of failures.

- Mechanical Seal Failure: This is often the first component to fail. A mechanical seal typically consists of two extremely flat rings (often one carbon, one ceramic) pressed together. A thin film of the pumped liquid lubricates and cools them. Without this liquid, the rings rub directly against each other, generating intense heat. The seal can crack, warp, or completely disintegrate in a matter of minutes, causing a major leak.

- Overheating Bearings and Motor: The heat generated at the seal travels down the shaft to the bearings, causing the grease inside them to break down. This leads to increased friction, noise, and eventual bearing seizure.

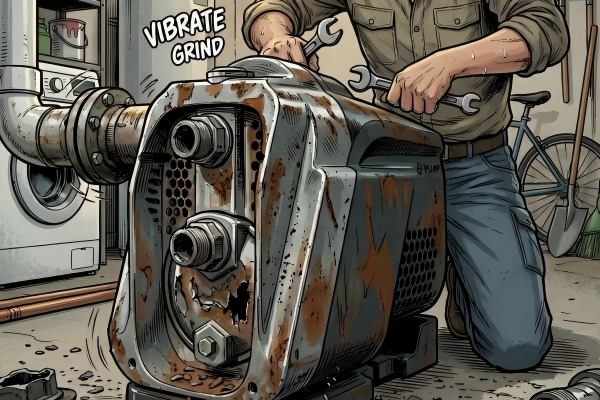

- Impeller and Casing Damage: If the pump runs dry for an extended period, the heat can become so intense that it damages the impeller itself. Thermoplastic impellers can melt or deform, while even metal impellers can warp, leading to imbalance and destructive vibrations.

A Note on Cavitation

While often confused with dry running, cavitation is a different but equally destructive phenomenon that can also result from priming issues.

Cavitation occurs when the pressure in the suction line drops below the vapor pressure of the liquid.

This causes tiny vapor bubbles to form. As these bubbles travel through the impeller to a higher-pressure area, they collapse violently.

This collapse creates micro-jets of liquid that blast the impeller surfaces with incredible force, causing pitting and erosion that looks like sponge-like damage over time.

Improper priming can leave air pockets that disrupt flow and create low-pressure zones, inducing cavitation.

| Risk of No Priming | Primary Consequence | Key Components Affected |

|---|---|---|

| Dry Running | Extreme overheating from friction | Mechanical Seal, Bearings, Impeller |

| No Flow | Pump cannot create suction or pressure | Entire Pumping Operation |

| Air Lock | Trapped air blocks liquid flow | Impeller and Casing |

| Cavitation | Vapor bubble collapse erodes surfaces | Impeller, Volute Casing |

When Priming Is Required (Standard Pumps)

You've just completed a perfect installation, but you overlook one final step.

You start the pump, and instead of the smooth flow of water, you hear a high-pitched, grinding noise.

This is the sound of a pump failing.

Forgetting to prime at critical moments is a common but costly mistake that can ruin a new pump before it even begins its service life.

Priming is not a one-time task.

For any standard centrifugal pump that isn't a self-priming or submersible model, you must prime it every time air has been allowed into the pump casing or suction line.

This ensures the pump is filled with liquid and ready to operate safely and effectively.

Knowing the specific situations that demand priming is essential for reliable pump operation and maintenance.

Each of these scenarios presents an opportunity for air to enter the system, creating the risk of an air lock and subsequent dry running.

Proactive priming is the only way to safeguard the equipment in these situations.

Key Scenarios Demanding Priming

A standard centrifugal pump operates in what is known as a "suction lift" condition when the liquid source is below the pump.

In this setup, the pump must be able to create a vacuum to draw the liquid up into the casing.

It can only do this if it's already full of liquid.

Therefore, priming is mandatory in several common situations.

Initial Startup and Installation

Every time a pump is installed for the first time, it is delivered dry from the factory.

The pump casing and the entire suction line are filled with nothing but air.

Before the motor is ever switched on, the system must be manually filled with the liquid it is intended to pump.

This initial prime is the most critical one in the pump's entire life, as it sets the stage for all future operations.

Skipping this step guarantees immediate dry running.

After System Maintenance or Draining

Maintenance often requires draining the system.

Whether you are replacing a seal, inspecting an impeller, or repairing a leaky pipe, the process almost always involves emptying the pump casing and suction lines.

Once the maintenance is complete and all connections are re-secured, the system is once again full of air.

It must be re-primed just as it was during the initial installation before it can be safely put back into service.

This also applies to systems that are drained seasonally, such as for winterization in cold climates.

If Air Leaks into the Suction Line

Air can inadvertently enter a system that is already in operation.

This is a more subtle but equally dangerous scenario.

A small leak in a suction line fitting, a cracked pipe, or a faulty foot valve can allow air to be continuously drawn into the pump.

If the pump is shut off, this air can accumulate in the pump casing.

When the pump tries to restart, it may be partially or fully air-bound and unable to re-prime itself, leading to dry run conditions.

This is why regular inspection of all suction-side plumbing is critical.

| Situation | Reason Priming is Needed | Risk of Not Priming |

|---|---|---|

| Initial Installation | Pump is shipped dry from the factory. | Immediate dry running and failure. |

| After Maintenance | Pump and lines are drained for service. | Damage upon restart if not re-filled. |

| Seasonal Shutdown | System is drained to prevent freezing. | Must be re-primed at the start of the new season. |

| Loss of Prime | Air has leaked into the suction line. | Pump becomes air-locked and cannot restart flow. |

When Priming Might Not Be Needed (Exceptions)

Constantly worrying about whether your pump will lose its prime is inefficient.

What if your pump could handle this automatically, ensuring reliable operation without manual intervention?

This is not a far-off dream; modern pump technology has already created solutions that eliminate this classic pumping problem.

While the rule "always prime a centrifugal pump" is a crucial guideline for standard models, it's not universal.

Certain pump designs and installation configurations make manual priming unnecessary.

These exceptions are specifically engineered to ensure the pump remains filled with liquid, ready to start on demand.

Understanding these exceptions is as important as knowing when to prime.

For business owners like Andrew, recommending a pump that fits one of these categories can be a major value-add for his customers, reducing their maintenance burden and increasing system reliability.

These solutions showcase how thoughtful engineering can overcome traditional operational hurdles.

Engineered Solutions That Eliminate Priming

The need for priming arises when a pump has to lift liquid from a source below it.

The following designs and setups cleverly bypass this challenge.

Flooded Suction Installations

This is the simplest and most effective way to eliminate priming concerns.

In a flooded suction (or "suction head") arrangement, the liquid source is positioned above the pump's inlet.

Gravity does all the work.

The liquid naturally flows down into the pump casing and suction line, keeping it permanently filled and primed.

As long as the liquid level in the source tank remains above the pump, there is no risk of air entering the casing when the pump is off.

This is the ideal setup for reliability and is common in industrial processes, building water supply systems, and booster applications where a break tank is used.

Submersible Pumps

A submersible pump is, by its very nature, always primed.

The entire pump unit, including the motor and impeller, is designed to be fully submerged in the liquid it is pumping (e.g., in a well, sump, or tank).

Because it is surrounded by liquid, the pump casing can never become air-bound.

This design is the standard for deep well applications, sump drainage, and wastewater management.

The Rise of Self-Priming Pumps

For situations requiring a suction lift where a flooded suction or submersible pump isn't feasible, the self-priming pump is the answer.

These pumps are a type of centrifugal pump, but with a crucial design modification: a large chamber or reservoir built into the pump casing.

Here's how they work:

- Initial Manual Prime: A self-priming pump must be filled with liquid once, during the very first installation.

- Retaining Liquid: When the pump stops, the design of the casing traps a significant amount of this liquid in the reservoir.

- The Self-Priming Cycle: When the pump restarts, it uses this trapped liquid to create a liquid-and-air mixture. This mixture is churned within the casing, and the air is gradually expelled through the discharge port. This process creates a vacuum in the suction line, which draws liquid up from the source until the pump and suction line are completely filled. At this point, the pump stops "recirculating" and begins to operate like a standard centrifugal pump.

Modern intelligent pumps, like many VFD booster pumps, often incorporate sophisticated dry-run protection with self-priming recovery algorithms.

If the pump detects a water shortage, it will shut down to prevent damage, then periodically attempt to restart in a self-priming cycle to check if water has returned.

This is a huge advantage, blending the power of a centrifugal pump with the intelligence to protect itself and restore operation automatically.

How Modern Intelligent Pumps Solve the Priming Problem

The risk of a pump running dry is a major liability.

Traditional protection methods are often basic, and once damage occurs, the cost of repair and downtime is significant.

For a business owner, providing a product that actively prevents its own destruction is a powerful selling point.

The best modern VFD booster pumps tackle the priming and dry-run problem head-on with advanced software and hardware.

They don't just pump water; they manage and protect the entire system.

This intelligence turns a potential catastrophic failure into a managed, non-destructive event, ensuring equipment longevity and user peace of mind.

Instead of relying on an operator to remember to prime the pump, an intelligent system monitors itself 24/7.

It uses real-time data from multiple sensors to understand its operational state.

This isn't just about on/off; it's about making smart decisions to preserve the hardware.

Let's break down how these systems, featuring comprehensive protection suites, provide a robust, multi-layered defense against dry running.

Integrated "Dry Run" Protection

The most critical feature is an intelligent water shortage, or "dry run," protection system.

This goes far beyond a simple float switch.

The pump's VFD controller constantly monitors key parameters like power consumption (amperage) and motor speed (RPM).

When a pump runs dry, the load on the motor drops significantly because it's no longer moving dense liquid.

The intelligent controller instantly recognizes this abnormal signature.

The Multi-Stage Recovery Algorithm

Instead of just shutting down and displaying an error, a truly smart pump initiates a recovery protocol.

Here is a typical example of how such a system works:

- First Detection: The pump detects a dry-run condition. It immediately stops the motor to prevent overheating and damage. It then enters a "self-priming" attempt, running for a set period (e.g., 360 seconds) to try and re-establish a prime. If successful, normal operation resumes.

- Short Sleep Period: If the first attempt fails, the pump assumes the water shortage is temporary. It will "sleep" for a short duration (e.g., 5-10 minutes) before trying again. This prevents the motor from continuously running and heating up while trying to prime.

- Extended Sleep Periods: If subsequent attempts also fail, the system intelligently extends the sleep duration. For example, after the second, third, and fourth failures, it might sleep for 2 hours between attempts.

- Long-Term Sleep: If the water shortage persists after multiple tries, the pump will enter a long-term sleep mode, perhaps trying again only every 6 or 12 hours. This conserves energy while still periodically checking for the return of the water supply.

This multi-stage approach is brilliant because it protects the pump while maximizing the chances of automatic recovery without any human intervention.

Supporting Protection Systems

This intelligent dry-run protection is part of a larger ecosystem of safeguards.

Other features work in concert to ensure reliability:

- Stall Protection: If the impeller gets jammed by debris (which could be mistaken for a no-load condition), the pump detects the motor stall and shuts down, preventing motor burnout.

- Overheating Protection: Temperature sensors on the control board (PCB) and directly monitoring water temperature provide another layer of defense. If the pump starts to overheat for any reason, including a prolonged and difficult priming cycle, it will shut down before damage can occur.

- Sensor Failure Warnings: The system even self-diagnoses. If a pressure sensor or temperature sensor fails, it will provide a specific error code, preventing the pump from operating on faulty data.

This comprehensive, automated protection transforms the centrifugal pump from a fragile tool that needs constant supervision into a robust, resilient, and self-sufficient piece of equipment.

For distributors and end-users, this means fewer service calls, longer product life, and far greater operational reliability.

Conclusion

Understanding pump priming is essential, but modern technology offers a far more reliable solution.

Intelligent VFD pumps with automated protection and recovery algorithms effectively eliminate the risks of dry running, ensuring longevity and peace of mind for your clients.

FAQs

Can a pump lose its prime?

Yes, a pump can lose its prime if air leaks into the suction line or if the foot valve fails, allowing water to drain back to the source.

What happens if you don't prime a pump?

If you don't prime a pump, it will run dry. This causes the mechanical seal and bearings to overheat and fail rapidly due to lack of lubrication and cooling.

Do you have to prime a brand new pump?

Yes, all standard centrifugal pumps are shipped dry and must be filled with liquid (primed) before their first use to prevent immediate damage.

How do you know if a pump needs priming?

If the pump is running but not building pressure or moving water, and you hear a higher-pitched whining sound, it likely needs to be primed.

Do all water pumps need to be primed?

No. Submersible pumps (which are underwater) and pumps in a flooded suction setup (where the water source is above the pump) do not need manual priming.

Can a centrifugal pump run backwards?

Yes, if wired incorrectly, a 3-phase motor can run backward. This causes very low flow and pressure and can potentially damage the pump or motor.

What is the difference between priming and cavitation?

Priming is filling the pump with liquid. Cavitation is the formation and collapse of vapor bubbles inside the pump, which erodes the impeller, often caused by poor suction conditions.

How long can a centrifugal pump run dry?

Only for a very short time, often less than a minute. The mechanical seal is typically the first part to be destroyed by the heat from friction.