Are high pump energy costs shrinking your margins? This constant expense hurts your competitiveness. Imagine slashing those costs by up to 50% with smarter pump technology.

A variable speed drive (VSD) pump can save a lot of energy. By matching motor speed to real-time water demand, it avoids running at full power nonstop. This intelligent control can cut electricity use by up to 50% compared to traditional fixed-speed pumps.

Saving up to 50% on energy sounds great, but that's just the start. The real magic is in how these pumps achieve such savings and what that means for your business beyond just lower bills. We'll break down the technology, explain how it works, and show you why so many distributors like you are making the switch. Let’s dive deeper into the mechanics and discover how VSD technology can transform your product line.

Why is VFD used in pumps?

Struggling with pumps that only run at full speed? This wastes energy and causes pressure fluctuations for your customers. A Variable Frequency Drive (VFD) offers precise, intelligent control.

VFDs are used in pumps to control the motor's speed. This allows the pump to adjust its output to match the exact water demand, maintaining constant pressure and drastically reducing energy consumption compared to fixed-speed pumps that are always running at 100% power.

To really understand the 'why', let's look at a standard pump. It has one speed: full power. It's either on or off. This is like driving your car by only flooring the gas pedal or slamming the brakes. It's inefficient and creates a lot of stress on the system. A Variable Frequency Drive (VFD), or VSD as we often call it, acts like a smart cruise control for the pump motor. It constantly monitors water pressure and adjusts the motor’s speed up or down to meet the demand perfectly. This means no more wasted energy from running at full blast when only a little water is needed. At RAFSUN, we pair VFDs with high-efficiency IE5 Permanent Magnet Synchronous Motors (PMSM). This combination is key. It delivers not just stable pressure but also incredibly quiet operation, often below 50dB [^2]. It’s a huge upgrade in performance and user experience.

| Feature | Traditional Pump | VSD/VFD Pump |

|---|---|---|

| Speed Control | Fixed (on/off) | Variable (adjusts to demand) |

| Energy Use | High, constant | Optimized, up to 50% less |

| Water Pressure | Fluctuates | Stable and constant |

| Noise Level | Louder | Super silent (<50dB) [^2] |

| Mechanical Stress | High (sudden starts/stops) | Low (soft starts) |

How do VFDs save energy?

Confused about how a pump can use so much power? Most of it is wasted by running at full speed unnecessarily. VFDs target this exact issue to deliver real savings.

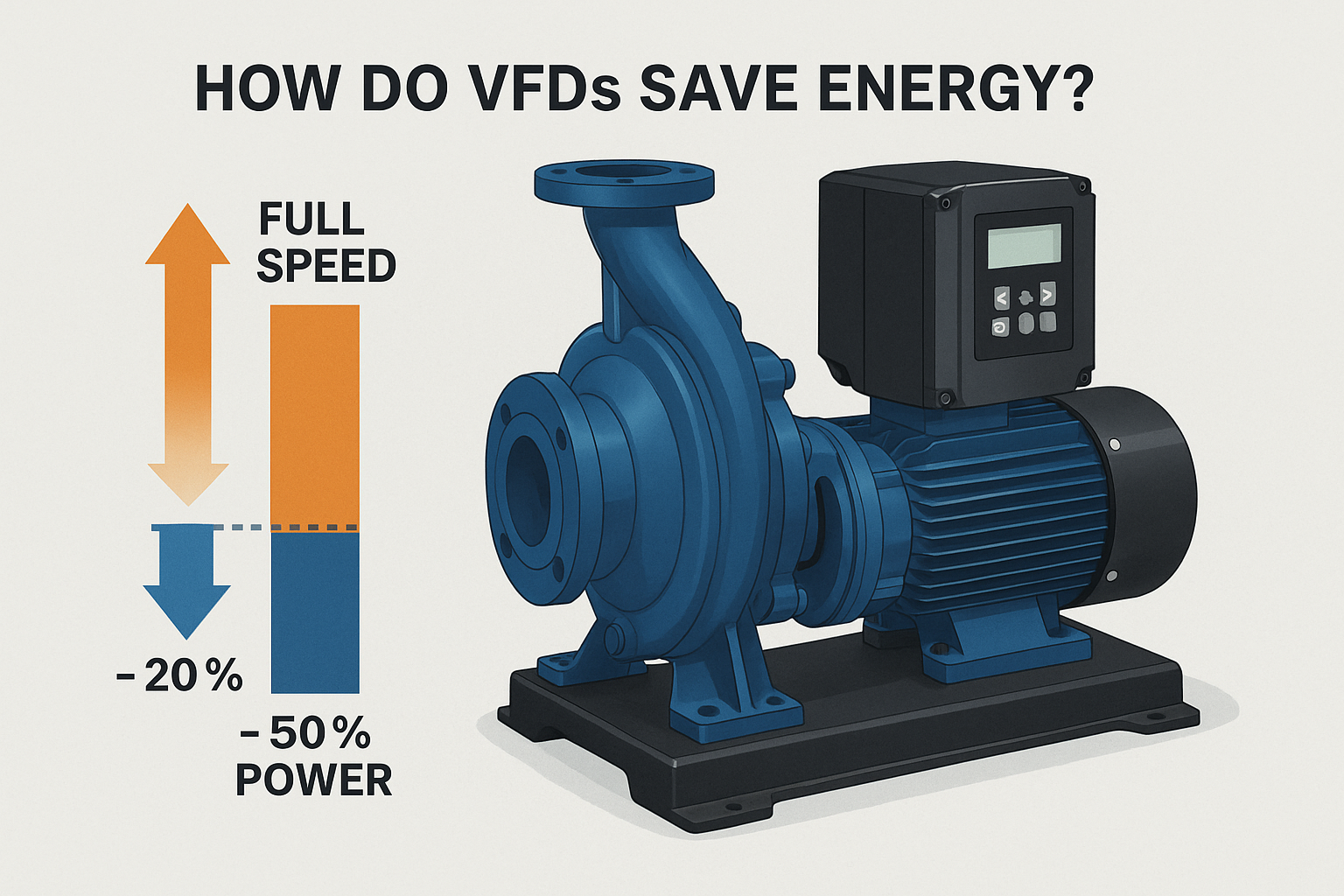

VFDs save energy by reducing the pump motor's speed. According to pump affinity laws, a small reduction in speed leads to a large reduction in power consumption. By precisely matching speed to demand, the VFD ensures the pump only uses the exact energy needed.

The secret to VFD energy savings lies in a core engineering principle. The relationship between a pump's speed and its power use isn't 1-to-1. If you reduce the pump's speed by 20%, you don't save 20% power. You actually save much more—the power savings are cubed! This is the game-changer. A traditional pump runs at 100% speed whether one tap is open or five. It's maximum power, all the time. A VFD, however, senses that only one tap is open and might slow the motor down to just 40% speed to maintain pressure. This small change in speed results in a massive drop in electricity use. Over a day, these small adjustments add up to huge savings, often between 30-50%. It also means less wear on the motor and bearings, because the pump isn't constantly starting hard and running at its limit.

Here’s a simple way to think about it:

- Minor Speed Reduction: Slightly slowing the motor.

- Major Power Reduction: The energy needed drops exponentially.

This is how we achieve such significant savings. The pump simply does not work harder than it has to at any given moment, and that intelligent efficiency is what you can pass on to your customers.

What is the ideal pressure for a VSD pump?

Do your customers complain about weak showers or fluctuating water flow? This is a sign of unstable pressure. VSD pumps solve this by maintaining a perfect, constant pressure.

The ideal pressure for a VSD pump is not one single value; it's the specific, constant pressure required by the application. You can set it anywhere within the pump's operating range [^1], for example from 2.0 to 5.0 bar, to perfectly match the needs of the building.

This is a common question I get from distributors, and the answer is simple: the ideal pressure is whatever your customer needs. That's the beauty of a VSD pump. You aren't locked into one pressure setting. Our pumps, for example, have a wide range of pressure settings, typically from 20% to 95% of the pump's maximum head [^1]. For a typical home, a constant pressure of 3.0 BAR is perfect for great showers and appliance performance. For a multi-story commercial building, you might need a higher constant pressure, like 4.5 BAR, to ensure strong flow on the top floors. A VSD pump maintains this set pressure perfectly. If more taps open, the pump speeds up. When they close, it slows down. The pressure at the tap stays the same. This eliminates the most common complaints about water systems.

| Application | Typical Ideal Pressure (BAR) | Why it's ideal |

|---|---|---|

| Single-Family Home | 2.5 - 3.5 BAR | Balances comfort (good showers) and efficiency. |

| Greenhouse Irrigation | 2.0 - 3.0 BAR | Provides gentle, consistent flow for sprinklers without wasting water. |

| Small Commercial Building | 3.5 - 5.0 BAR | Ensures adequate pressure across multiple floors and for various uses. |

| High-Rise Building | 4.0 - 6.0+ BAR | Requires higher pressure to overcome gravity and supply top floors. |

How many hours a day should you run a VSD pump?

Concerned about the costs and wear from running a pump all day? It's a valid worry with old pumps. But VSD technology is designed for continuous, intelligent operation.

A VSD booster pump is designed to run 24/7. It stays in a standby mode with minimal power consumption when there is no water demand. It only actively runs when water is needed, ensuring constant pressure without wasting energy or causing premature wear.

You should think of a VSD pump as being 'on duty' 24/7, not 'running' 24/7. This is a critical difference. The pump's intelligent controller is always active, monitoring the system pressure. But the motor itself only runs when water is actually being used. When there’s no demand, it enters a low-power standby mode, waiting for a tap to open. This means it can run for just a few minutes an hour or for several hours straight, depending entirely on usage. More importantly, our pumps are built for this. They include 14 different protection functions, like safeguards against running dry, overheating, and power surges, which provides a safe and satisfying user experience [^1]. For applications that need 100% uptime, you can even link two pumps. They can operate in an 'auto-alternating' mode, where they take turns running to evenly distribute wear and ensure there's always a backup [^1]. This is a feature our distributors love.

Conclusion

VSD pumps cut energy costs by up to 50%, deliver constant pressure, and offer smart, reliable 24/7 operation. They are a superior choice for any modern water system.