What is an inverter pump and how does it benefit my business?

Struggling with customer complaints about fluctuating water pressure and high energy bills? These issues reflect poorly on the products you sell, impacting your reputation and bottom line.

An inverter pump, also known as a VSD (Variable Speed Drive) booster pump, is a smart water pump that uses a built-in inverter to adjust its motor speed. This allows it to perfectly match water flow to demand, maintaining constant pressure while saving up to 50% on energy costs.[^2]

As someone who has been in the pump manufacturing business for over a decade here at RAFSUN, I've seen firsthand how technology transforms a simple product into a powerful solution. The move from a basic pump to an inverter pump is one of those huge leaps. It’s not just about moving water anymore; it’s about doing it intelligently, efficiently, and quietly. For business owners like you, understanding this technology is key to demonstrating value and securing higher-margin sales. Let's break down exactly how this works and why it's a game-changer for your inventory.

How do pump inverters actually work?

Have you ever tried to explain complex tech to a customer who just wants a simple solution? It can be tough. The magic of an inverter pump is how it converts this complexity into simple, tangible benefits.

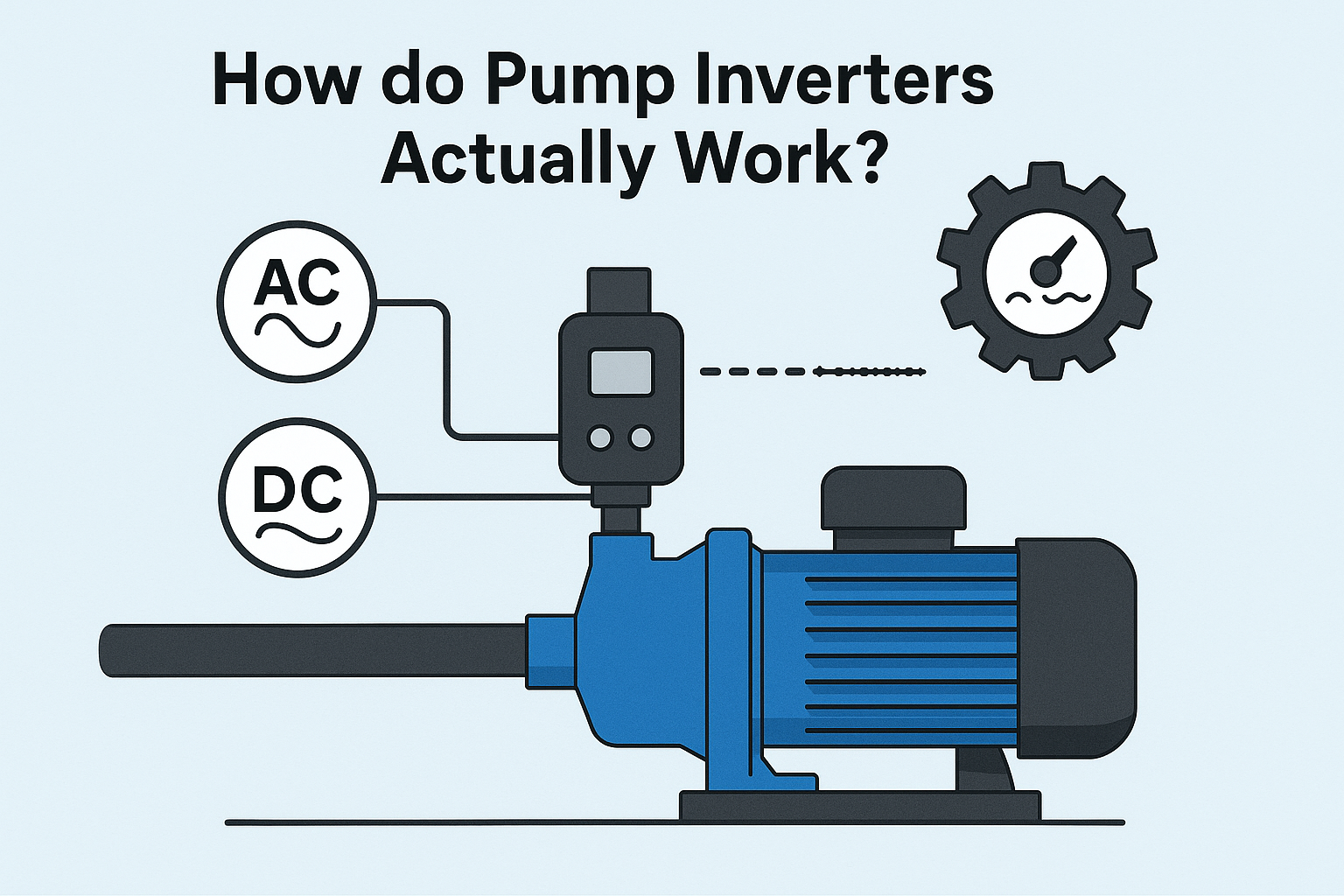

A pump inverter works by intelligently managing the motor's speed. It takes standard AC power, converts it to DC, and then creates a new, controlled AC signal. This new signal's frequency can be changed, which directly controls the pump motor's speed to meet the system's exact pressure demands.[^2]

Let's dive deeper into this process. It sounds technical, but the concept is straightforward when you look at the components. I've worked with my 30+ R&D engineers to perfect this system, and it comes down to three key parts working together.

The Power Conversion Core

The inverter's main job is to act as a power interpreter. It takes the fixed-frequency power from the grid (usually 50Hz or 60Hz) and gives the pump motor exactly the frequency it needs for a specific speed. Think of it like a car's gas pedal, but for an electric motor. Instead of just being on or off, it can be at 30%, 65%, or 90% power, whatever is needed. This is made possible by our high-efficiency Permanent Magnet Synchronous Motors (PMSM), which are rated IE5 for maximum energy efficiency.[^3]

The Intelligent Brain

The system is governed by a controller with integrated sensors. A pressure sensor in the pipeline constantly measures the water pressure.

- If a tap is opened and pressure drops, the sensor tells the inverter to speed up the motor.

- If the tap is closed and pressure rises, the inverter slows the motor down.

This feedback loop is what creates the "constant pressure" experience that end-users love.

The Result: A Smarter Pumping Cycle

| Cycle Stage | Fixed-Speed Pump Action | Inverter (VSD) Pump Action |

|---|---|---|

| Demand Starts | Turns on at 100% speed. | Gently ramps up to required speed. |

| Demand Varies | Stays at 100% or cycles on/off. | Adjusts speed smoothly in real-time. |

| Demand Stops | Shuts off abruptly. | Gently ramps down to a stop. |

This intelligent control not only provides a better user experience but also leads to massive energy savings and protects the pump from wear and tear.

So, can an inverter really run a pump reliably?

Are you worried about adding a complex electronic component to a traditionally mechanical product? You don't want to sell a system that might fail and lead to costly warranty claims for your business.

Yes, an inverter is designed specifically to run a pump motor. In fact, it runs it better and safer than a direct connection to the grid. It provides precise speed control, soft-start capabilities, and integrated motor protection, which significantly extends the pump’s lifespan and reliability.[^1]

I remember talking to Leon, a distributor from South Africa. He's a sharp guy who focuses on quality but is always conscious of keeping his customers happy. Initially, he was skeptical about inverter pumps because he thought the electronics added a point of failure. He was used to the simple reliability of older pumps. During a visit, I showed him a demo of our BWE series pump starting up. There was no sudden jolt, no loud noise, and no "water hammer" shock in the pipes. The pump just smoothly and quietly came to life. He immediately saw the value—not just in the technology but in the reduction of customer complaints about noise and pipe vibrations. An integrated system, where the pump and inverter are designed for each other, is far more reliable than a mismatched system.

Designed as a Complete System

At RAFSUN, we don't just add an inverter to an existing pump. Our VSD pumps are designed from the ground up as a single, integrated unit. The motor, the pump hydraulics, and the inverter controller are all optimized to work together. The controller itself is sealed with potting compound to protect the printed circuit board (PCB) from moisture and vibration, ensuring long life even in tough conditions.[^4]

The Power of Soft Start

A traditional pump starts with a massive electrical and mechanical shock. This surge can stress electrical systems and cause "water hammer" that damages pipes and fittings. An inverter provides a "soft start," gradually ramping up the motor speed. This is gentler on the entire system, from the motor windings to the pipe joints, which is a key factor in extending the equipment's lifespan and a major selling point for you.

What key functions does a pump inverter offer?

Are you looking for products with features that deliver real, explainable value? Basic pumps just move water. Smart pumps solve problems, and that is what helps you stand apart from your competition.

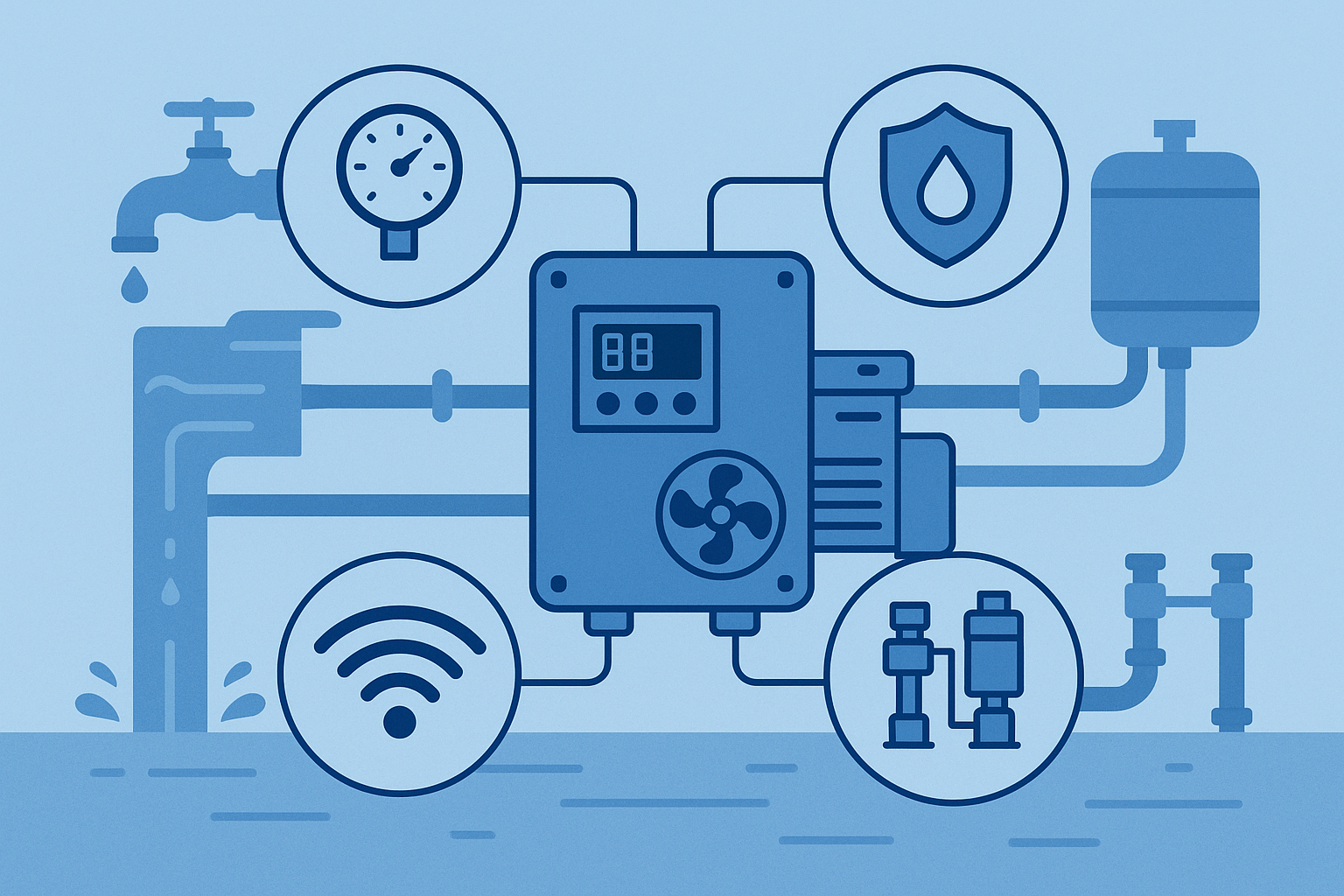

Beyond just speed control, a modern pump inverter offers a suite of functions. These include maintaining constant water pressure, providing numerous system protections (like dry run and overcurrent), and enabling advanced features like WiFi remote monitoring and multi-pump linking.[^1]

When we designed our VSD pump series, we talked to distributors and end-users to understand their biggest pain points. The result was a set of features that provide peace of mind and real-world benefits. You aren't just selling a pump; you are selling a complete water management solution. This allows you to position yourself as an expert and command better margins.

Here’s a breakdown of the functions you can offer your customers with a RAFSUN inverter pump:

| Function Category | Specific Function | Value Proposition for Your Business |

|---|---|---|

| Core Performance | Constant Pressure Control | Delivers a luxury user experience, eliminating pressure drop complaints. |

| Super Silent Operation | Runs at less than 50dB, perfect for residential use where noise is a concern.[^5] | |

| Wide Pressure Setting | Pressure can be adjusted from 20-95% to fit any application precisely.[^1] | |

| System Protection | 14 Built-in Protections | Includes dry-run, over-current, over-voltage, and overheating protection. This drastically reduces failures and warranty claims.[^1] |

| IP55 Protection | The motor and controller are protected against dust and water jets, ensuring durability.[^6] | |

| Advanced Control | Optional WiFi Function | Allows remote control and real-time monitoring via a smartphone app. A powerful feature for tech-savvy customers and for remote diagnostics.[^1] |

| Optional Pump Link Mode | Allows two pumps to work together, either for double the output or as a backup (Host/Slave mode), opening up sales for larger projects.[^1] |

These features transform the conversation from "how much does it cost?" to "what problems does it solve?". They provide clear, tangible benefits that justify the investment.

How does an inverter pump differ from an ordinary water pump?

Are your customers questioning the price difference between a standard pump and an inverter pump? They might look similar, but the value is in the performance, efficiency, and long-term savings.

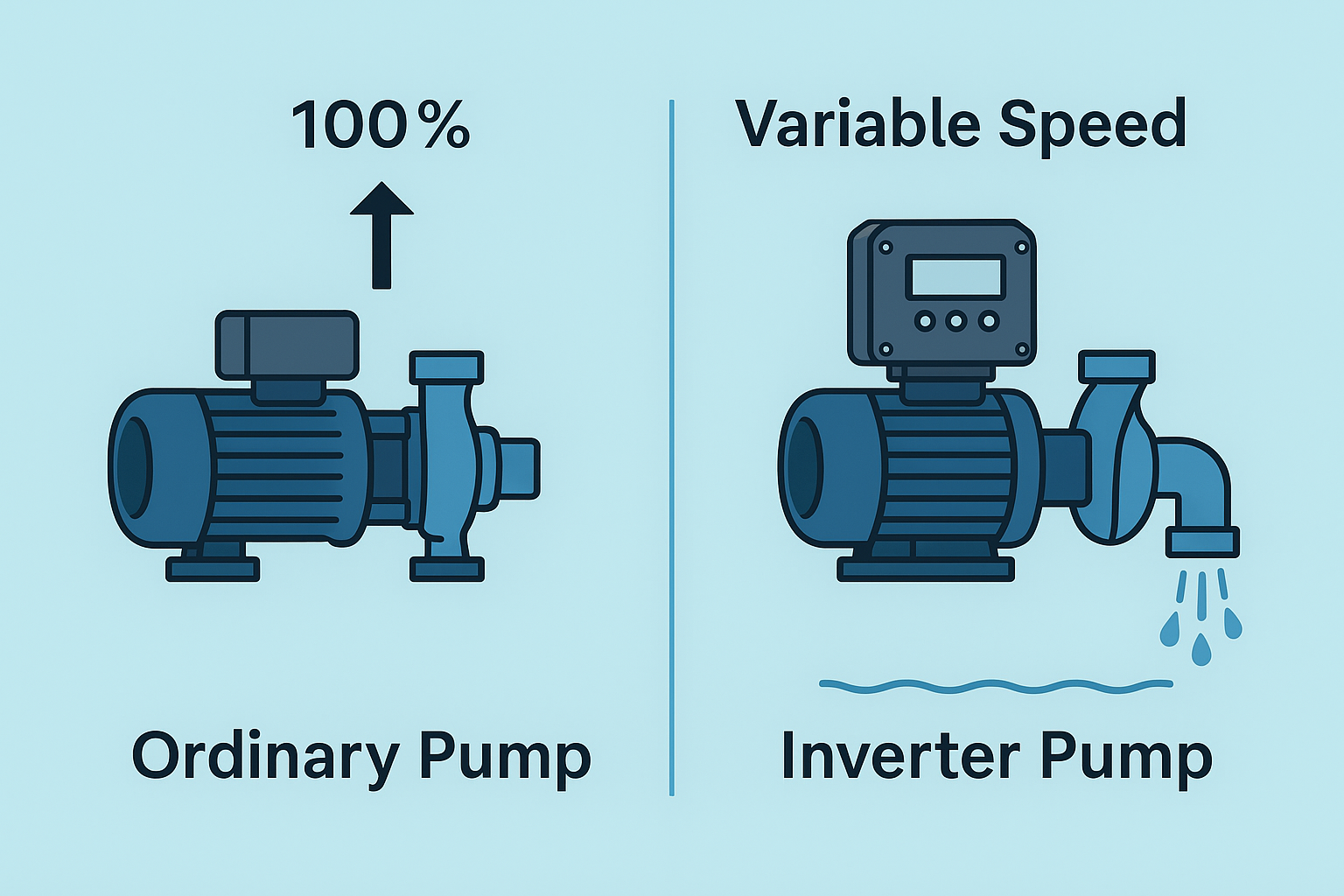

The crucial difference is intelligent control versus brute force. An ordinary pump is either off or running at 100% speed. An inverter pump intelligently adjusts its speed to the exact demand, providing constant pressure, saving huge amounts of energy, running quieter, and lasting much longer.[^2]

Explaining this difference is key to your sales process. When a customer sees the higher initial price, they need to understand the lower Total Cost of Ownership (TCO). As a business owner, you know that the purchase price is only part of the story. The real cost includes energy consumption and maintenance over the product's life. This is where inverter pumps offer unbeatable value. For example, our pumps use premium materials like AISI304 stainless steel or brass impellers, which are corrosion-resistant and food-grade certified, ensuring durability that standard pumps can't match.[^3]

Let's look at a direct comparison:

| Feature | Ordinary Fixed-Speed Pump | RAFSUN Inverter (VSD) Pump |

|---|---|---|

| Speed Control | Fixed (100% or 0%) | Fully Variable (adjusts automatically) |

| Energy Use | High and inefficient | Highly efficient, saves up to 50%[^2] |

| Water Pressure | Fluctuates heavily | Perfectly constant and stable |

| Noise Level | Loud and disruptive | Super silent (<50dB)[^3] |

| Equipment Lifespan | Shorter due to start-up shock and constant high-speed wear | Extended due to soft start and optimized speed |

| Intelligence | None. Just a motor. | A complete smart system with 14 protections.[^1] |

| Materials | Often basic cast iron | Premium materials like AISI304 Stainless Steel or Brass impellers.[^5] |

When you lay it out like this, the choice becomes clear. The inverter pump isn't just a pump; it's an upgrade to the entire water system. It's an investment in efficiency, comfort, and reliability that pays for itself over time.

Conclusion

In short, inverter pumps provide intelligent control for constant pressure, deliver significant energy savings, and ensure a longer, quieter operational life, making them the superior choice for modern water systems.