The Ultimate Guide: 5 Revealing Facts About a Variable Frequency Drive Pump?

Tired of fluctuating water pressure and high energy bills? These problems cost you money and lead to unhappy customers, damaging your reputation. A VSD pump is the simple solution.

A Variable frequency drive pump is a smart system that uses a VFD to automatically adjust its motor speed. It matches water demand perfectly, delivering constant pressure while dramatically cutting energy use. This makes it a highly efficient and reliable choice for many applications.

I’ve spent over a decade manufacturing this technology here at RAFSUN. My most successful partners, the B2B importers and distributors from South Africa to Mexico, often build their entire brand on the reliability of this one product. They always start by asking the same questions you probably have right now. So, let me share what I've learned and break down everything you need to know about the Variable frequency drive pump.

So, What Exactly is a Variable Frequency Drive in a Pump System?

Confused by all the technical jargon from suppliers? It's frustrating when you can't get a simple explanation for the products you sell. Let me give you the clear definition.

A variable frequency drive (VFD) is the electronic controller—the "brain"—of a modern pump. It regulates the electrical frequency supplied to the motor, which in turn controls the motor's speed. This allows the pump to adapt its performance to real-time demand instead of running full-speed constantly.

The Critical Difference: VFD Pumps vs. Traditional Fixed-Speed Pumps

Let’s be honest, the old way of doing things was simple but inefficient. A traditional pump motor is either ON, running at full G-force, or it's OFF. There is no in-between. To manage this crude power, installers needed a whole collection of extra parts: a large pressure tank to store water, a pressure switch to tell the pump when to turn on and off, and check valves. This system works, but it has major drawbacks. It wastes energy, the pump motor suffers from the harsh starts and stops, and end-users complain about the pressure dropping right before the pump violently kicks in.

A Variable frequency drive pump completely changes the game. It doesn't operate in a binary on/off state; it works on a smooth, continuous spectrum. Think of it like the difference between a simple light switch and a modern dimmer. The old pump just slams the lights on. The VFD pump allows you to smoothly adjust the brightness to the exact level you need, creating a much better experience and saving energy.

This fundamental difference has a massive impact on performance, durability, and user satisfaction. As a distributor, understanding this is the first step to explaining the value of a Variable frequency drive pump to your customers. Here is a simple breakdown I use with my partners:

| Feature | Traditional Fixed-Speed Pump | Variable Frequency Drive Pump |

|---|---|---|

| Motor Speed | Constant (full speed only) | Variable (adjusts from low to high) |

| Energy Use | High, runs at max power every time | Optimized, with energy savings up to 50% |

| Water Pressure | Fluctuates, causing user annoyance | Perfectly constant and stable |

| System Wear | High due to harsh mechanical starts/stops | Reduced, "soft starts" extend motor life |

| Noise Level | Loud, especially on startup | Super silent, often under 50dB[^2] |

| System Complexity | Requires external pressure tanks/switches | Integrated, all-in-one smart system |

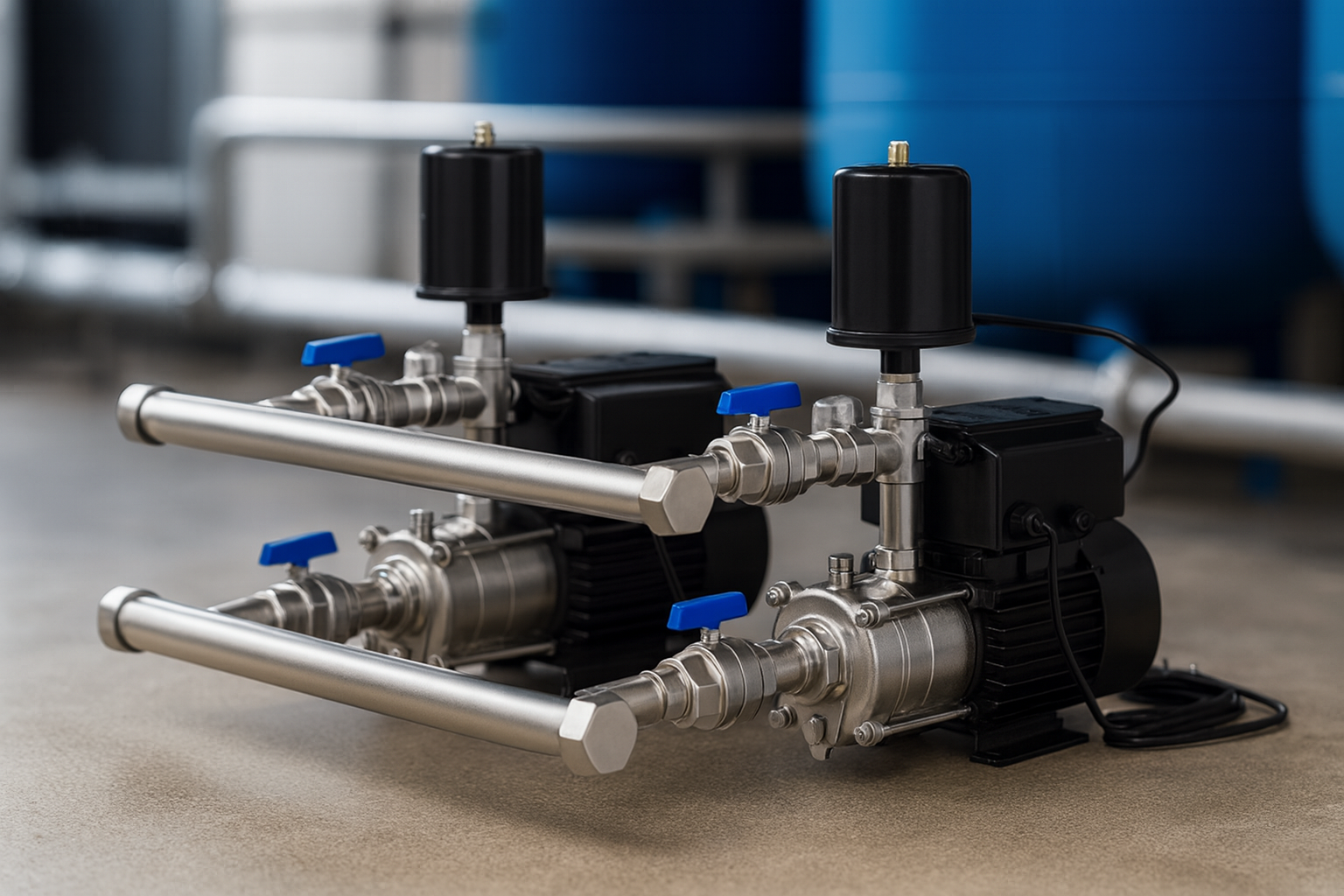

I remember visiting a client's customer in South Africa. He was an installer, and he showed me an old setup in a beautiful home. It had a huge, noisy fixed-speed pump connected to a massive blue pressure tank. The system took up a whole corner of the garage. He replaced it with one of our compact RAFSUN Variable frequency drive pump units. The homeowner’s feedback was immediate. First, they couldn't believe how quiet it was. Second, they raved that the shower pressure was finally perfect, for the first time since they built the house. This is the kind of feedback that builds a brand.

How Does a Variable Frequency Drive Pump Actually Work?

Is this technology just a "black box" to you? It's difficult to sell a product with confidence if you're not sure how it really works. Let me lift the curtain for you.

It works in a simple feedback loop. A pressure sensor detects a change in water demand (like a tap opening). It signals the VFD, which instantly adjusts the motor's speed to restore the target pressure. The pump works smarter, not harder, to maintain perfect stability.

The Intelligent Feedback Loop: Sensor, Drive, and Motor

The genius of a Variable frequency drive pump isn't in one single component, but in how three parts work together in a continuous, high-speed conversation. The entire operation is a seamless cycle of measuring, comparing, and adjusting.

1. The Pressure Sensor (The Sentry)

This small but vital device is usually installed on the outlet pipe of the pump. Its only job is to constantly measure the water pressure inside the pipe. It's the system's eyes and ears, sending a nonstop stream of data back to the VFD. It is incredibly sensitive and can detect the smallest drop or rise in pressure.

2. The Variable Frequency Drive (The Brain)

The VFD, or inverter, is where the decisions are made. When you install the pump, you program a desired pressure setpoint—for example, 45 PSI. The VFD’s microprocessor constantly compares the real-time pressure reading from the sensor to this 45 PSI target. If there is any difference, it instantly calculates the exact motor speed required to close that gap. If the pressure is too low, it calculates how much faster the motor needs to spin. If it's too high, it calculates how much it needs to slow down.

3. The Pump and Motor (The Muscle)

Based on the VFD's calculations, it sends a precisely tailored electrical signal to the pump’s motor. This signal tells the motor exactly how fast to rotate.

Let’s walk through a real-world scenario:

- Setpoint: The system is set to a constant 45 PSI. All taps are closed, so the pump is running at a very low speed or is in standby mode.

- Demand: Someone opens a shower tap. Water starts flowing out, and the pressure in the pipe instantly drops to, say, 42 PSI.

- Measure: The pressure sensor detects this 3 PSI drop and immediately relays this information to the VFD.

- Compare & Adjust: The VFD sees the 42 PSI reading and compares it to the 45 PSI setpoint. It instantly computes that the motor needs to accelerate. It changes the frequency of the electricity going to the motor, perhaps from 20Hz to 45Hz.

- Action: The motor spins up, the pump impeller turns faster, and more water is pushed into the system. The pressure rises back to exactly 45 PSI within a fraction of a second.

The user in the shower never feels that initial pressure drop. All they experience is strong, unwavering water pressure. When they turn the shower off, the reverse happens just as quickly and smoothly, preventing the damaging "water hammer" effect common with old pumps that slam off at full speed. This smooth ramping is what we call a "soft start" and "soft stop," which dramatically reduces mechanical stress and extends the pump's lifespan. Our RAFSUN pumps also use this intelligence to offer built-in protections against dry running, overloads, and blockages, safeguarding the entire system[^1].

What’s the Secret Behind How a VFD Itself Operates?

Do the electronics seem intimidating? You might worry about selling and servicing complex technology. But the core principle is surprisingly simple and robust, making it a reliable choice for your business.

At its heart, a VFD performs a three-step electrical conversion. It takes standard AC power from the wall, converts it into DC power, and then inverts it back into a new, adjustable-frequency AC signal to control the motor's speed with incredible precision.

Inside the VFD: The Three-Stage Power Conversion Process

As a manufacturer, I believe my partners deserve to understand the quality of the technology inside the products they sell. While the electronics are advanced, the process can be broken down into three logical stages. This is what's happening inside the sealed controller of every Variable frequency drive pump.

Stage 1: The Rectifier (AC to DC Conversion)

The process starts with the standard power from the wall. This is Alternating Current (AC), which in most parts of the world is delivered at a fixed frequency of 50 or 60 Hertz. The VFD’s first component, a rectifier, takes this incoming AC power. The rectifier is essentially a set of high-power diodes that act as one-way gates for electricity. It effectively "flattens" the alternating wave of AC power, converting it into Direct Current (DC).

Stage 2: The DC Bus (Power Reservoir)

The newly created DC power isn't perfectly smooth yet; it has ripples. It flows from the rectifier into a section called the DC bus, which consists of several large capacitors. Think of these capacitors as a small, temporary reservoir for electrical energy. Their job is to filter and smooth out the DC voltage, creating a clean, stable, and readily available pool of DC power. This step is critical for protecting the motor and ensuring the final output is clean and precise.

Stage 3: The Inverter (DC to 'New' AC Conversion)

This is the final and most critical stage, where the "variable frequency" magic happens. The inverter section is made up of a series of powerful, fast-switching transistors. Using a technique called Pulse Width Modulation (PWM), these transistors "chop up" the smooth DC power from the DC bus. They switch on and off thousands of times per second, releasing tiny pulses of DC voltage.

By controlling the width and timing of these pulses, the inverter can construct a brand new, synthetic AC sine wave. Most importantly, it can build this new wave at any frequency it desires. If it needs the motor to run slowly, it might create a 25Hz signal. If it needs full power, it might create a 60Hz signal.

This ability to create a custom frequency on demand is what gives the Variable frequency drive pump its incredible control. It’s not just about changing speed; it’s about having total command over the motor's performance. At RAFSUN, to ensure the long-term durability of these critical components, we fully seal our Printed Circuit Boards (PCBs) in a protective potting compound. This shields the electronics from moisture, dust, and vibration—common killers of electronics in the field—and is a key quality mark I tell my partners to look for[^3].

How Do You Select the Perfect Variable Frequency Drive Pump for Your Business?

Facing a sea of options can be paralyzing. Choosing the wrong pump for your inventory wastes time and money, and stocking an underpowered or poor-quality unit can damage your brand's reputation.

To select the right Variable frequency drive pump, focus on four key things: the required flow rate (Q.Max) and pressure/head (H.Max), the specific application (residential vs. commercial), the available power supply, and the build quality of the components for long-term reliability.

The Distributor's Checklist for VFD Pump Selection

As a B2B partner, your success is my success. I want you to stock the products that will move quickly and build your reputation. Here is the exact checklist I go through with all my new distributors a lot like you, to ensure they choose the perfect inventory for their market.

1. Analyze the Performance Curve: Match Power to the Need

Every professional pump has a performance curve. This chart is its resume. It shows the relationship between flow rate (how much water it moves, Q) and head (how high it can push that water, H). You absolutely must match this curve to your customer’s needs. Don't just look at the maximum values (Q.Max, H.Max). Look at the rated or "Best Efficiency Point" (BEP), which is where the pump operates most efficiently. For a large single-family home with a couple of bathrooms, a model like our BWE-750, with a rated flow of 3.5m³/h at 27m of head, is often a perfect fit[^4]. For a small commercial building or a large luxury home, you'll need to step up to a model like our BWD-2200, which can deliver a powerful 12m³/h at 40m of head[^6]. Understanding these curves is the most important technical skill for selling pumps.

2. Match the Application: The Right Tool for the Right Job

A Variable frequency drive pump is not a one-size-fits-all product. The right choice depends entirely on where it will be installed.

- Residential: The key selling points are constant pressure and quiet operation. Look for pumps rated as "super silent" (under 50dB) and with a compact, easy-to-install design[^5].

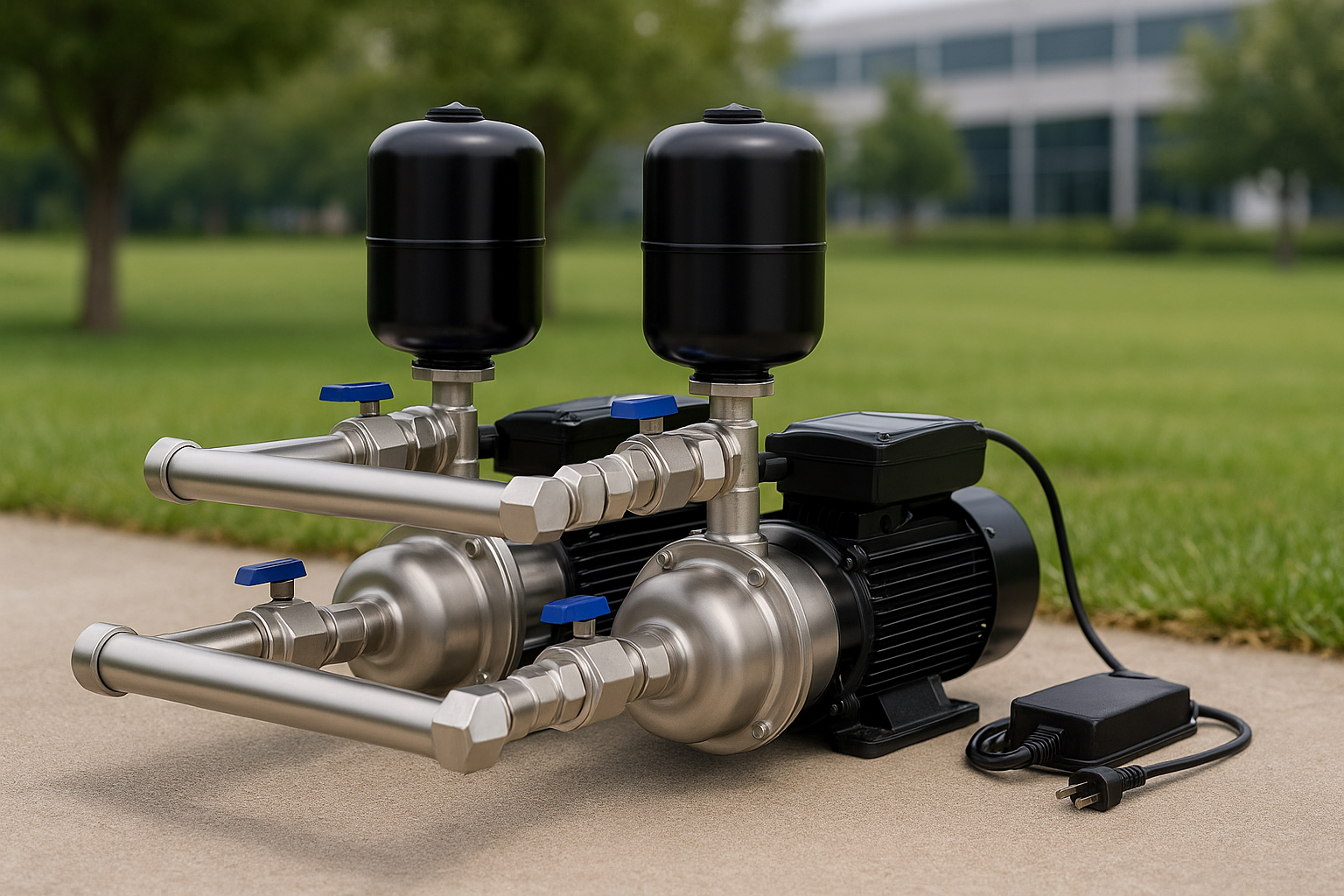

- Commercial: Reliability and scalability are everything. For high-rise buildings, hotels, or small industrial plants, you need more than just a single pump. Look for models with advanced features like our Pump Link Mode. This allows you to connect two pumps in a Host/Slave configuration. They can work together to double the water output during peak times or alternate operation to equalize wear and provide critical backup if one needs maintenance[^1]. This feature turns a product sale into a high-value system solution.

- Agricultural: For applications like fish farming or greenhouse irrigation, consistency is king[^1]. The ability to precisely set and hold a pressure or flow rate can directly impact crop yields or livestock health.

3. Vet the Build Quality: Your Reputation Depends On It

Your customers trust you. The products you sell carry your name. That’s why you must look past the spec sheet and inspect the build quality.

- Wetted Parts: What materials touch the water? I tell all my partners to demand quality here. We use premium materials like AISI 304 stainless steel or brass for our impellers because they resist corrosion and wear, ensuring a long life and clean water[^3][^5].

- Protection Rating: What is the pump's IP (Ingress Protection) rating? Our pumps are rated IP55, which means the motor and electronics are protected from dust and jets of water [^2]. It’s a ruggedness rating that matters in the real world.

- Internal Electronics: Are the electronics protected? As I mentioned, we seal our PCBs in potting compound to prevent failure from humidity or vibration[^3]. Ask your supplier about these details. It separates the serious manufacturers from the rest.

Here is a quick table to help you evaluate a Variable frequency drive pump for your inventory:

| Selection Factor | Example Spec (from RAFSUN models) | Why it Matters to a Distributor |

|---|---|---|

| Max Head (H.Max) | BWD-1200: 86m[^6] | Determines the max vertical height. Crucial for multi-story buildings. |

| Max Flow (Q.Max) | BWD-2200: 20m³/h[^6] | The total volume of water. Essential for applications with many outlets. |

| Silent Operation | < 50dB[^2] | A massive selling point for residential use. A problem solver. |

| Impeller Material | Premium AISI304 Stainless Steel or Brass[^3][^5] | A clear sign of a premium product. It means longer life and better water quality. |

| Advanced Linking | Host & Slave Pump Mode[^1] | Offers redundancy and scalability. A high-value feature for commercial sales. |

| Wide Voltage Range | 165-260V[^4] | Ensures reliable operation in areas with unstable power grids. |

What Are the 3 Main Game-Changing Uses for a Variable Frequency Drive Pump?

Viewing a Variable frequency drive pump as just a simple replacement for an old pump is a big mistake. This thinking limits your market reach and your profit potential.

The three most powerful applications for a Variable frequency drive pump are: revolutionizing residential water supply with constant pressure, ensuring robust reliability in large commercial buildings, and providing precise control for modern agricultural and industrial processes[^1].

1. The Residential Revolution: Perfect Pressure, Total Silence

This is the largest and most accessible market for most of my distributors. Every day, homeowners around the world are frustrated by weak showers, trickling kitchen faucets, and noisy pumps that shake the whole house. A Variable frequency drive pump is the direct, modern solution to all these problems.

- The Problem It Solves: It eliminates the inconsistent water pressure that plagues homes with poor municipal supply or traditional well pump systems.

- The VFD Solution: It delivers a constant, comfortable, "luxury hotel" water pressure experience to every tap. Because of its "super silent" operation (often below 50dB), it can be installed in a utility closet or basement without becoming a nuisance[^2]. For health-conscious customers, you can also highlight that a VFD system often reduces or eliminates the need for a large pressure tank where water can stagnate.

- The Business Case for You: This is a high-volume product category with very high customer satisfaction. Happy homeowners are the best form of marketing. It is a fantastic product to build a local brand reputation for quality and performance. Our REB and BWE series are specifically designed to dominate this market space[^2][^5].

2. Commercial and High-Rise Reliability: Power and Intelligence

In a commercial setting like a hotel, office building, hospital, or factory, water is not a luxury; it's a critical utility. A failure in the water pressure system isn't an inconvenience—it's a business-stopping catastrophe that can cost thousands of dollars per hour.

- The Problem It Solves: It reliably meets the massive and highly variable water demands of commercial buildings. Think about the morning rush in a hotel when hundreds of showers turn on at once.

- The VFD Solution: The pump automatically scales its output up and down to match demand perfectly, saving a tremendous amount on electricity compared to running huge, fixed-speed pumps 24/7. More importantly, this is where advanced features become critical selling points. Our Pump Link Mode is a game-changer here[^1]. An installer can link two pumps. They can be set to run alternately to equalize wear (Timing-alternating mode), or they can be set so that a "Slave" pump automatically kicks in to assist the "Host" pump during peak demand. This provides scalability, efficiency, and critical redundancy.

- The Business Case for You: These are high-value project sales. For a distributor, this means you're selling a complete system solution, not just a pump. This involves higher-end pumps, control systems, and potentially service contracts, all of which lead to significantly larger profit margins. Our heavy-duty BWD series is built precisely for these demanding jobs[^3].

3. Specialized Agriculture and Industry: Precision Where It Counts

The final major application requires you to think beyond just moving water, and focus on how it's moved. In many modern processes, the precision of the flow is as important as the flow itself.

- The Problem It Solves: It provides the exact, stable, and repeatable pressure or flow rates needed for sensitive processes like high-tech greenhouse irrigation, aquaculture (fish farming), poultry facilities, or certain manufacturing steps.

- The VFD Solution: A Variable frequency drive pump can be programmed to maintain an exact pressure, which is vital for these operations. In a large-scale drip irrigation system, for example, uniform pressure ensures every plant gets the same amount of water, maximizing crop yield. The wide range of pressure settings, often from 20% to 95% of the pump's capacity, gives the operator incredible flexibility and control that is impossible with a fixed-speed pump[^2].

- The Business Case for You: This opens up profitable niche markets. These customers are typically less price-sensitive and far more focused on quality, reliability, and precision. They need a technical partner who understands their process, not just a supplier who can ship a box. Selling into these markets positions your business as a high-value expert.

Conclusion

In short, a Variable frequency drive pump offers unparalleled energy efficiency, intelligent control, and reliability. This technology is your key to happier customers and a more profitable business.