Unveiling the 5 Essential Secrets of the Horizontal Multistage Pump?

Struggling with low water pressure or inefficient, noisy pumps? This costs you energy, money, and leads to system failures. A RAFSUN horizontal multistage pump could be the powerful, reliable solution you've been looking for.

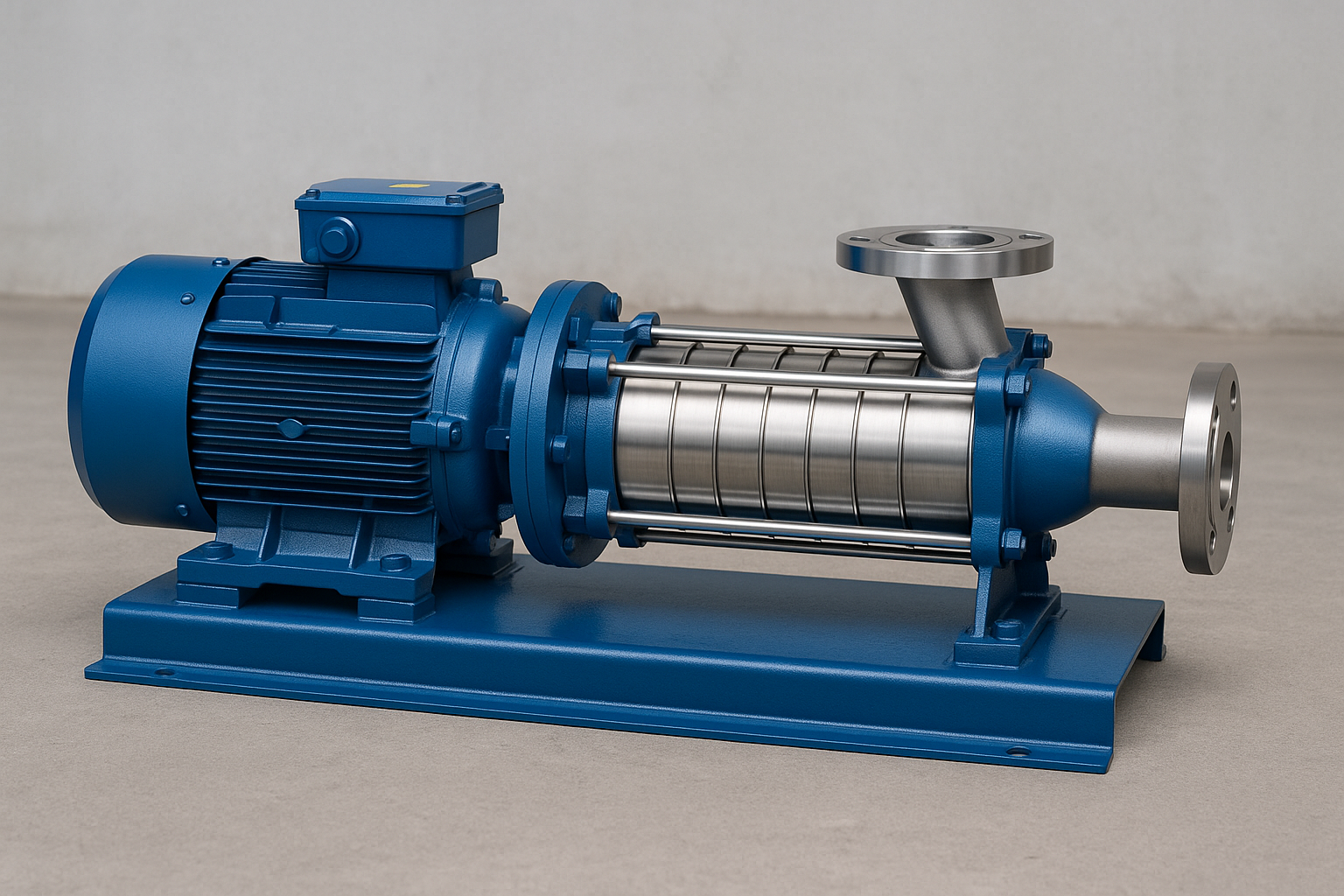

A horizontal multistage pump is a centrifugal pump with two or more impellers on a horizontal shaft. This design generates progressively higher pressures, making it perfect for applications needing a high-pressure, stable water supply like building boosting, irrigation, and industrial processes.

Now that you know the basics, you might have more questions. How do they differ from other pumps? What makes them so effective, and how can you be sure you're choosing the right one for your clients? Let's dive deeper into the world of the horizontal multistage pump to uncover the answers. You will want to read this before you make your next purchase commitment.

What Exactly Makes a Horizontal Multistage Pump a High-Pressure Powerhouse?

Are you confused by the term 'multistage' and what it really means for pump performance? This confusion can lead to choosing the wrong pump, wasting both money and effort. Let me clarify exactly what a horizontal multistage pump is and why its design is key to its power.

A horizontal multistage pump uses multiple impellers on a single horizontal shaft inside one casing. Each impeller, or "stage," adds pressure to the water, creating a powerful, high-pressure output from a compact and stable design. It’s a game-changer for high-head applications.

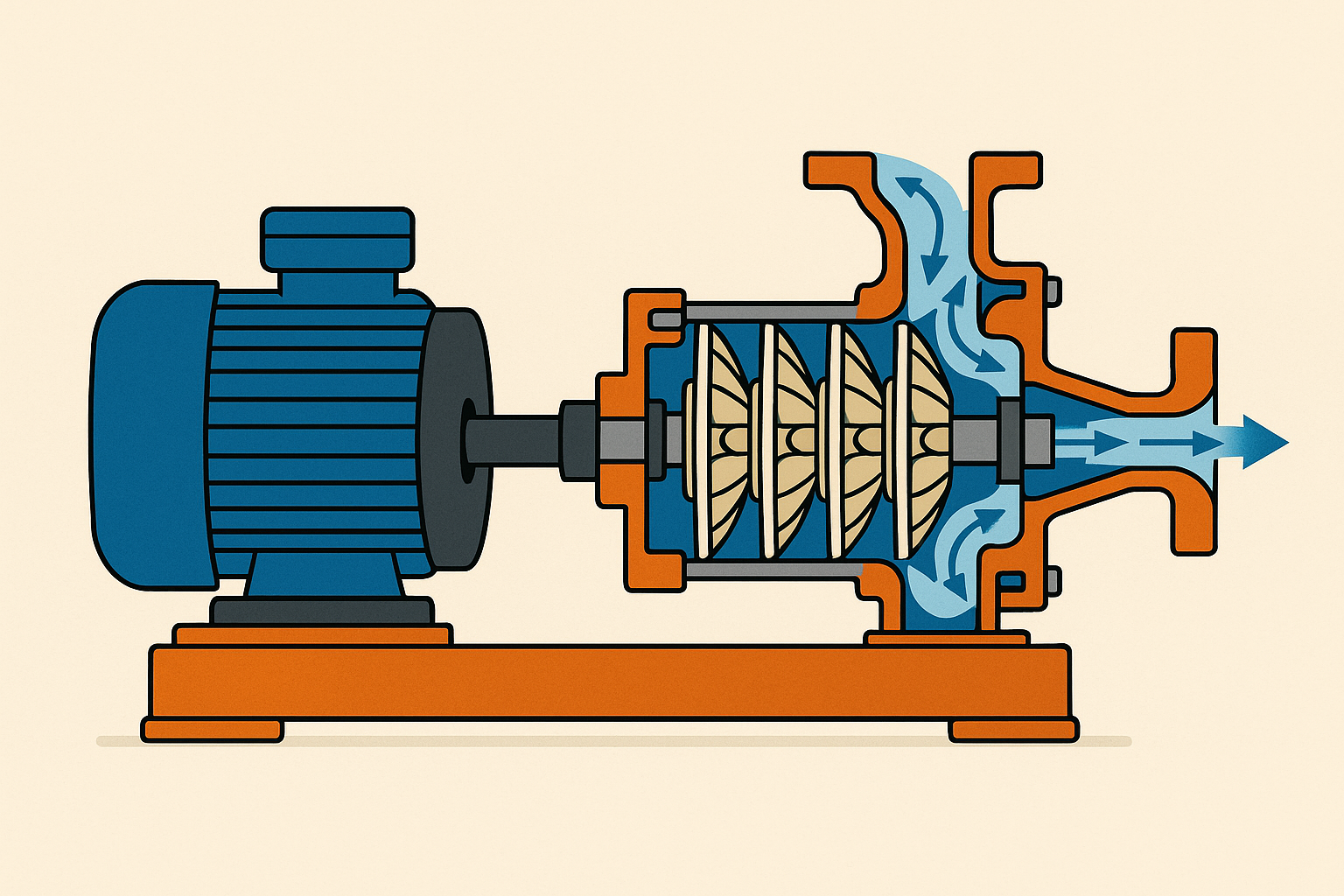

To really understand a horizontal multistage pump, you have to think of it as a team of pumps working together in a single, streamlined unit. The core concept is the "stage." Each stage consists of an impeller and a diffuser. The impeller is the spinning part that grabs the water and throws it outward with force. The diffuser is the stationary part that catches that fast-moving water and expertly converts its speed into pressure.

The magic happens in series. Water enters the first stage, where its pressure gets a boost. From there, it doesn't exit the pump. Instead, it's expertly guided into the center of the next stage. The second impeller grabs it and boosts the pressure again. This process repeats through every stage in the pump. If you have a four-stage pump, the water gets pressurized four separate times before it finally exits. This cumulative effect is what allows a relatively small pump to generate incredibly high pressures.

At RAFSUN, we machine these critical components with precision. The impellers in our models are often made from high-quality AISI304 stainless steel, which is not only incredibly durable but also corrosion-resistant and food-grade certified. This ensures a long, reliable service life. These impellers are mounted on a robust, single horizontal shaft, supported by industrial-grade bearings to ensure smooth, quiet, and efficient operation for years. It's a simple concept, but perfecting the engineering is what makes the horizontal multistage pump a true powerhouse.

| Number of Stages | Starting Pressure | Pressure Gain Per Stage | Final Outlet Pressure |

|---|---|---|---|

| 1 (Single-Stage) | 2 Bar | +3 Bar | 5 Bar |

| 3 (Multistage) | 2 Bar | +3 Bar x 3 Stages | 11 Bar |

| 5 (Multistage) | 2 Bar | +3 Bar x 5 Stages | 17 Bar |

Vertical vs. Horizontal Multistage Pump: Which One is Right for You?

Choosing between a vertical and a horizontal pump configuration can be confusing for distributors. The wrong choice could lead to installation headaches for your customers, inefficient use of space, or even maintenance challenges down the line. Let's clearly outline the key differences so you can make the perfect choice.

The main difference lies in the shaft orientation. A horizontal multistage pump has a horizontal shaft, offering a low profile, easy maintenance access, and excellent stability. A vertical pump has a vertical shaft, which saves significant floor space and often handles higher temperatures.

When I talk with my distributors, like my friend Leon in South Africa, this is a frequent topic. The decision between a horizontal and vertical pump isn't about which is "better" overall, but which is better for a specific job.

The most obvious difference is the footprint. A horizontal multistage pump is low and spread out. It's perfect for places with low ceilings, like under a workbench or in a basement mechanical room. A vertical pump is tall and slim, taking up very little floor space, which makes it the go-to choice for crowded utility rooms in large commercial buildings.

Maintenance is another huge factor. With a horizontal pump, the motor and pump casing are side-by-side and easily accessible. A technician can service the bearings, seals, or motor without any special equipment. I remember Leon telling me his teams prefer our horizontal models for residential projects because they can complete service calls much faster. In contrast, servicing a vertical pump often requires lifting the motor off the top, which can be more complex and time-consuming.

Hydraulically, there's a difference in their suction capabilities. Vertical pumps often have lower Net Positive Suction Head (NPSH) requirements. In simple terms, this means they are better at lifting water from a source that is below the pump. However, for most boosting applications where the pump has a flooded suction, a horizontal multistage pump is perfectly suited and often more cost-effective.

| Feature | Horizontal Multistage Pump | Vertical Multistage Pump |

|---|---|---|

| Space Footprint | Low profile, requires more floor area. | Tall profile, saves floor area. |

| Maintenance | Components are easily accessible on the ground level. | Often requires lifting equipment to service the motor. |

| Best Application | General boosting, irrigation, low-ceiling spaces. | High-rise buildings, boiler feed, tight spaces. |

| Stability | Excellent stability due to low center of gravity. | Good stability, requires proper mounting. |

What is the Ultimate Purpose of a Multistage Pump System?

Have you ever wondered why some applications demand a multistage pump instead of a simpler, single-stage one? Using the wrong type of pump can lead to inadequate pressure, massive energy waste, and premature equipment failure for your end-users. The purpose of a multistage pump is simple but powerful: to generate high pressure efficiently and reliably.

The primary purpose of a multistage pump is to overcome high system resistance by generating high pressure (head). It does this by adding pressure in series across multiple stages, making it ideal for moving water over long distances, to great heights, or for reverse osmosis.

Think of "head" as the total work a pump has to do. It's a combination of lifting water vertically and pushing it against friction in the pipes. A single-stage pump is great for moving high volumes of water at low pressure, but it has a physical limit to the head it can generate efficiently. When an application's required head exceeds that limit, you bring in a multistage pump.

The purpose is to meet that high-pressure demand without compromise. Here are some perfect examples:

- High-Rise Buildings: The purpose here is to fight gravity. To get strong, consistent water pressure to a penthouse apartment on the 20th floor, you need a pump that can generate enough head to push water all the way up. Many of our RAFSUN pumps are designed for this exact purpose in commercial and residential towers.[^1]

- Long-Distance Irrigation: For a farmer with a large field, the goal is to ensure the sprinklers at the far end have the same pressure as the ones near the pump. A horizontal multistage pump overcomes the friction loss in hundreds of meters of pipe to make this possible, making it essential for modern agriculture.[^2]

- Reverse Osmosis (RO) Systems: The purpose here is to create extremely high pressure. To force water through the fine membranes of an RO system to purify it, you need pressures that a single-stage pump simply can't achieve.

- Boiler Feedwater: In industrial settings, the purpose is to inject water into a highly pressurized boiler. The pump must generate a pressure greater than the steam pressure inside the boiler itself.

The true modern purpose, however, is to do this intelligently. By pairing a horizontal multistage pump with a Variable Speed Drive (VSD), we create a system that doesn't just produce high pressure—it produces the exact pressure needed at any given moment. This is a game-changer, saving up to 50% on energy costs and transforming a brute-force tool into a precise, efficient water management solution.

How Does a Horizontal Multistage Pump Actually Work Its Magic?

The inner workings of a pump can seem like a complex black box. Not understanding the mechanical process makes it hard to troubleshoot issues for your customers or truly appreciate the incredible engineering that goes into these machines. Let's break down the step-by-step process of how a horizontal multistage pump moves and pressurizes water.

A horizontal multistage pump works by using an electric motor to rotate a shaft with multiple impellers. As water enters the first impeller, it is thrown outward by centrifugal force. It is then guided to the next impeller, where the process repeats, boosting pressure at each stage before exiting.

The process is a beautifully simple and effective dance of physics. Let’s follow a drop of water on its journey through one of our RAFSUN pumps.

- Suction Inlet: The journey begins at the suction nozzle. The a pump creates a low-pressure zone, and atmospheric pressure pushes water into the pump, right into the "eye" or center of the very first impeller.

- Stage 1 - Energy Conversion: The motor is spinning the shaft, and the first impeller spins with it at high speed. As the water enters the spinning impeller, it's captured by vanes and flung outward by powerful centrifugal force. This action dramatically increases the water's speed (kinetic energy). This high-speed water then flows into a stationary diffuser, which is a set of carefully shaped channels that slow the water down. As the water slows, its kinetic energy is converted into pressure energy.

- Crossover to the Next Stage: The now-pressurized water isn't finished. It is guided through a channel in the pump casing to the eye of the second impeller.

- The Process Repeats: Stage 2 does the exact same thing as Stage 1, but it's starting with water that is already pressurized. So, it adds more pressure on top of the first boost. This continues for every stage in the horizontal multistage pump.

- Final Discharge: After passing through the final stage, the now highly pressurized water is collected in a chamber called the volute and directed out of the discharge nozzle, ready to do its work.

The "magic," however, is controlled by the "brain" — our VSD controller. This smart device monitors the pressure in the pipes. If someone opens a tap, the pressure drops, and the VSD instantly tells the motor to speed up to maintain constant pressure. If the tap is closed, it slows the motor down, saving energy. This intelligent control, combined with the raw power of multistage design, is what makes a modern horizontal multistage pump so special.

What Are the 5 Game-Changing Advantages of a Horizontal Centrifugal Pump?

Investing in a new pump system is a major decision for your business as a distributor. Choosing a pump that isn't reliable, efficient, or easy to maintain can damage your reputation and hurt your bottom line. I want to show you the clear, game-changing advantages of stocking a quality horizontal multistage pump.

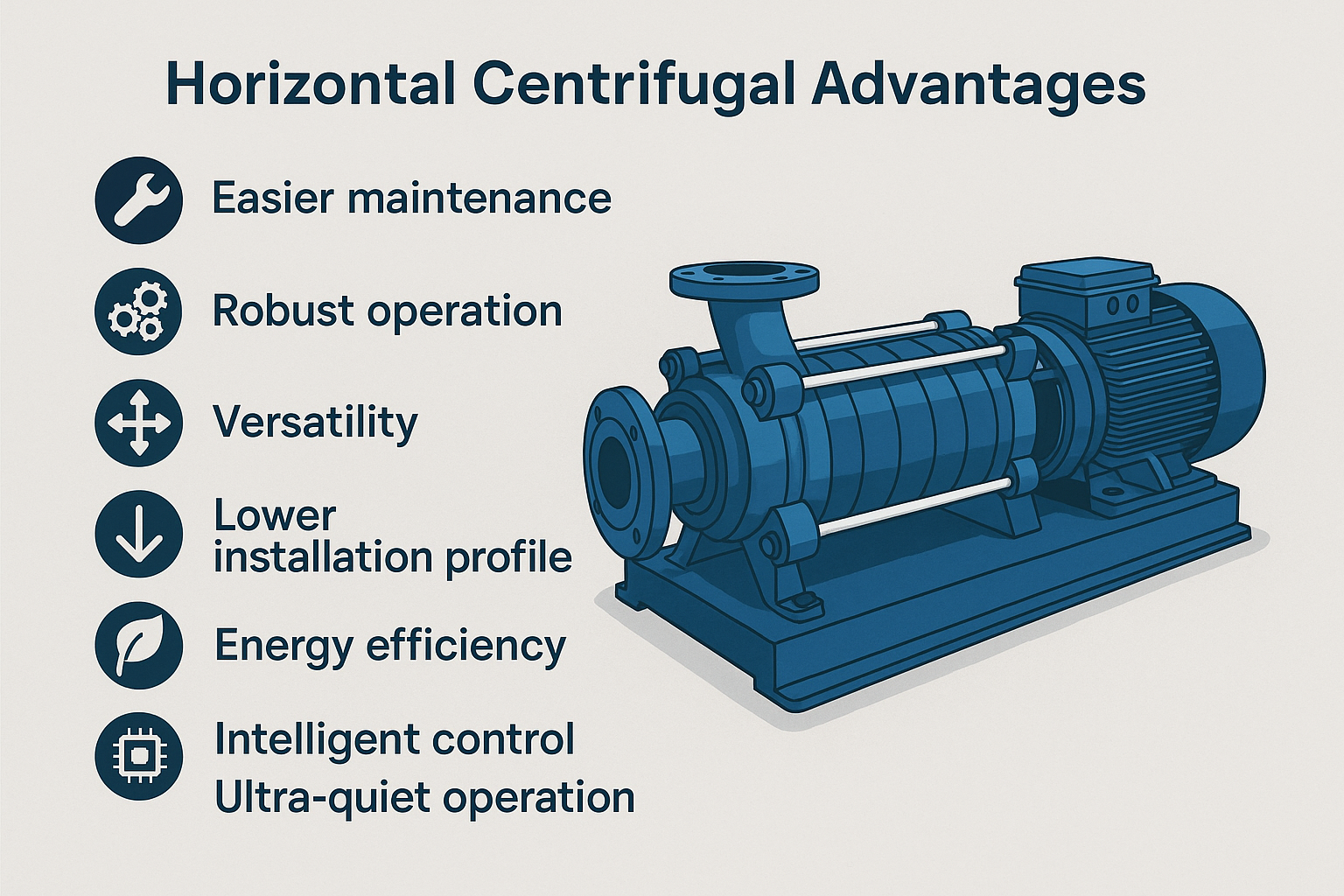

Key advantages of a horizontal centrifugal pump include easier maintenance, robust operation, versatility, and a lower installation profile. When combined with modern VSD technology, they offer incredible energy efficiency, intelligent control, and ultra-quiet operation.

Over my decade in this industry, I have seen these advantages translate directly into success for my partners. Here are the top 5 that you can confidently promise to your customers:

-

Remarkable Energy Efficiency. This is the number one selling point in today's market. Our RAFSUN pumps pair a multistage design with an IE5-rated Permanent Magnet Synchronous Motor (PMSM) and a Variable Speed Drive (VSD). This combination is revolutionary. It means the pump only uses the exact amount of energy needed, reducing electricity consumption by 30-50% compared to traditional pumps. For an end-user, this means significant savings on their utility bills.

-

Superior Durability and Stability. A horizontal multistage pump has a low center of gravity, which makes it inherently stable and reduces vibration. This leads to less wear and tear on components. We build on this foundation by using premium materials. We use AISI304 stainless steel for impellers, industrial-grade bearings, and protect our controllers with sealed potting compound. Our pumps undergo over 1000 hours of UV resistance testing and 144+ hours of salt spray testing to ensure they last.

-

Ultra-Quiet Operation. Noise is a major concern, especially in residential and light commercial settings. Nobody wants a pump that sounds like a jet engine kicking on every time they use water. Our VSD pumps are engineered to operate at less than 50 decibels.[^3] That is quieter than a normal conversation. This is a huge quality-of-life advantage that your customers will notice and appreciate.

-

Ease of Maintenance. Time is money for service technicians. The horizontal layout of these pumps means the motor, couplings, seals, and bearings are all easily accessible at ground level. This simplifies inspection, service, and repair, reducing downtime and labor costs for the end-user. It's a practical design that makes life easier for everyone.

-

Intelligent Control and Versatility. These are not just dumb machines. Our pumps are smart. They are suitable for an incredible range of applications, from household water supply and agricultural irrigation to commercial water systems.[^4] They come with 14 different built-in protection functions, including safeguards against dry running, overcurrent, and overheating.[^5] With optional Wi-Fi connectivity, users can even monitor and control their pump remotely from their phone, a feature that provides ultimate peace of mind and control. This makes the horizontal multistage pump a versatile and powerful tool for any water management challenge.

Conclusion

A horizontal multistage pump provides high pressure via its staged design. It's stable, easy to maintain, and supremely efficient and intelligent when paired with modern RAFSUN VSD technology.