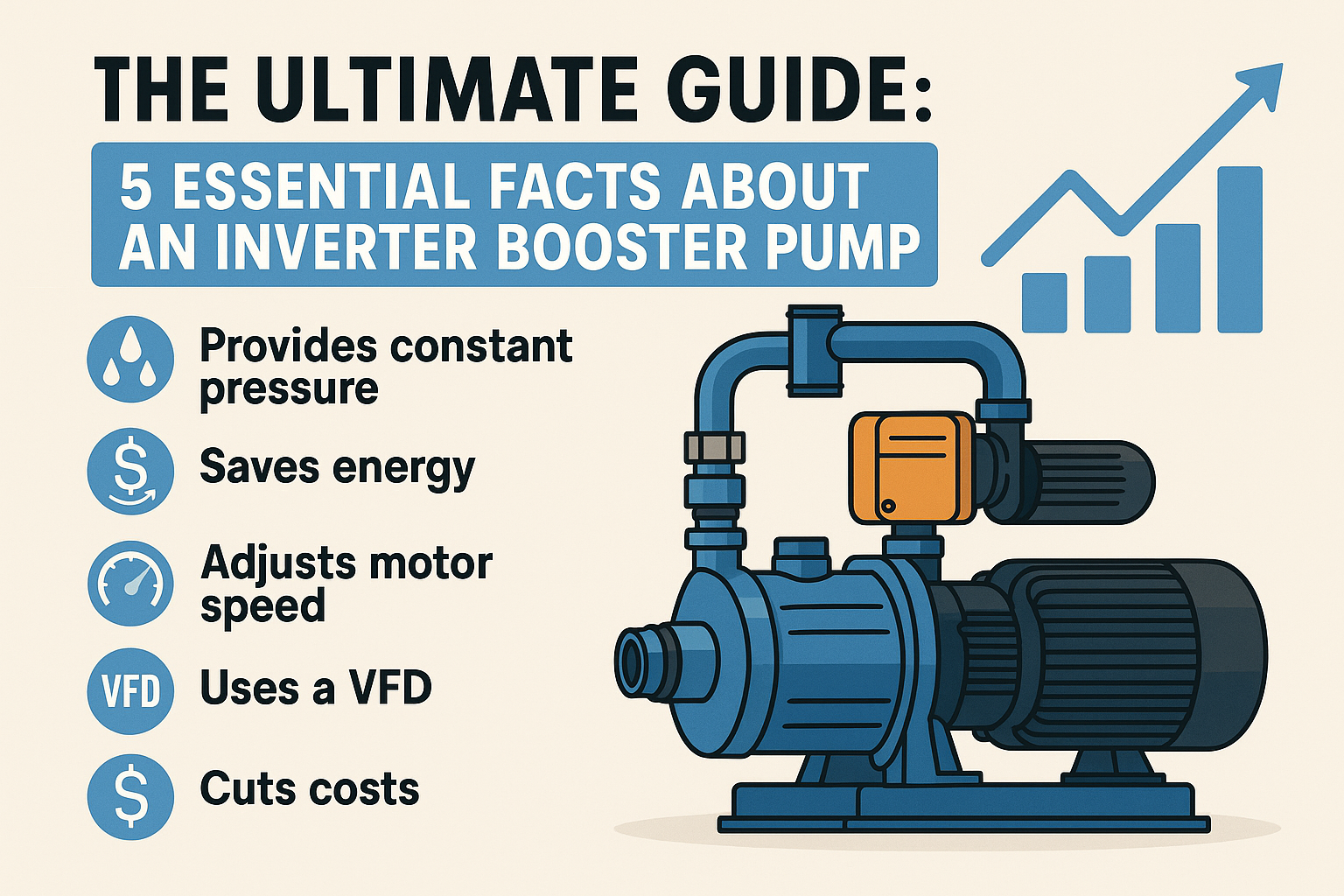

The Ultimate Guide: 5 Essential Facts About an Inverter Booster Pump?

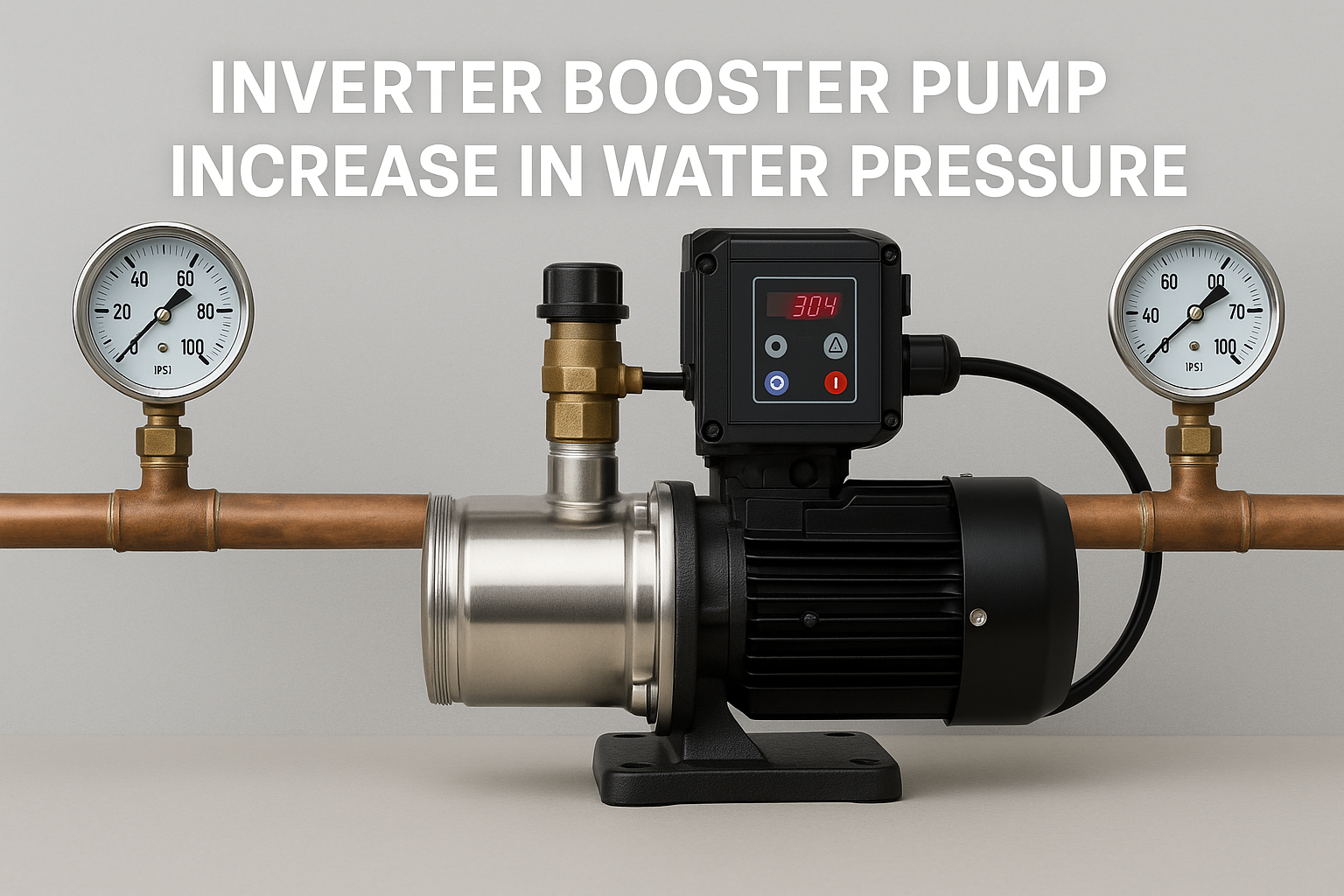

Tired of fluctuating water pressure? Frustrated by high energy bills from your old pump? An inverter booster pump solves this by providing powerful, constant pressure while saving you serious money.

An inverter booster pump is a smart water pump that uses a variable frequency drive (VFD) to adjust its motor speed in real-time. This ensures consistent water pressure throughout your property while significantly cutting energy consumption, sometimes by up to 50% 1. It’s the modern solution for reliable water supply.

Now that you have the basic idea, you might be wondering what makes these pumps tick. As a manufacturer, I've spent over a decade perfecting this technology, and I can tell you it's a game-changer for my clients. To truly understand the power of an inverter booster pump, we need to break it down into its core parts. Let's start by looking at the "inverter" component.

First, what exactly is an inverter pump anyway?

Confused by the term "inverter pump"? It's a common source of questions I get from distributors. This technology is the key to modern, efficient water management, and I'll explain it simply.

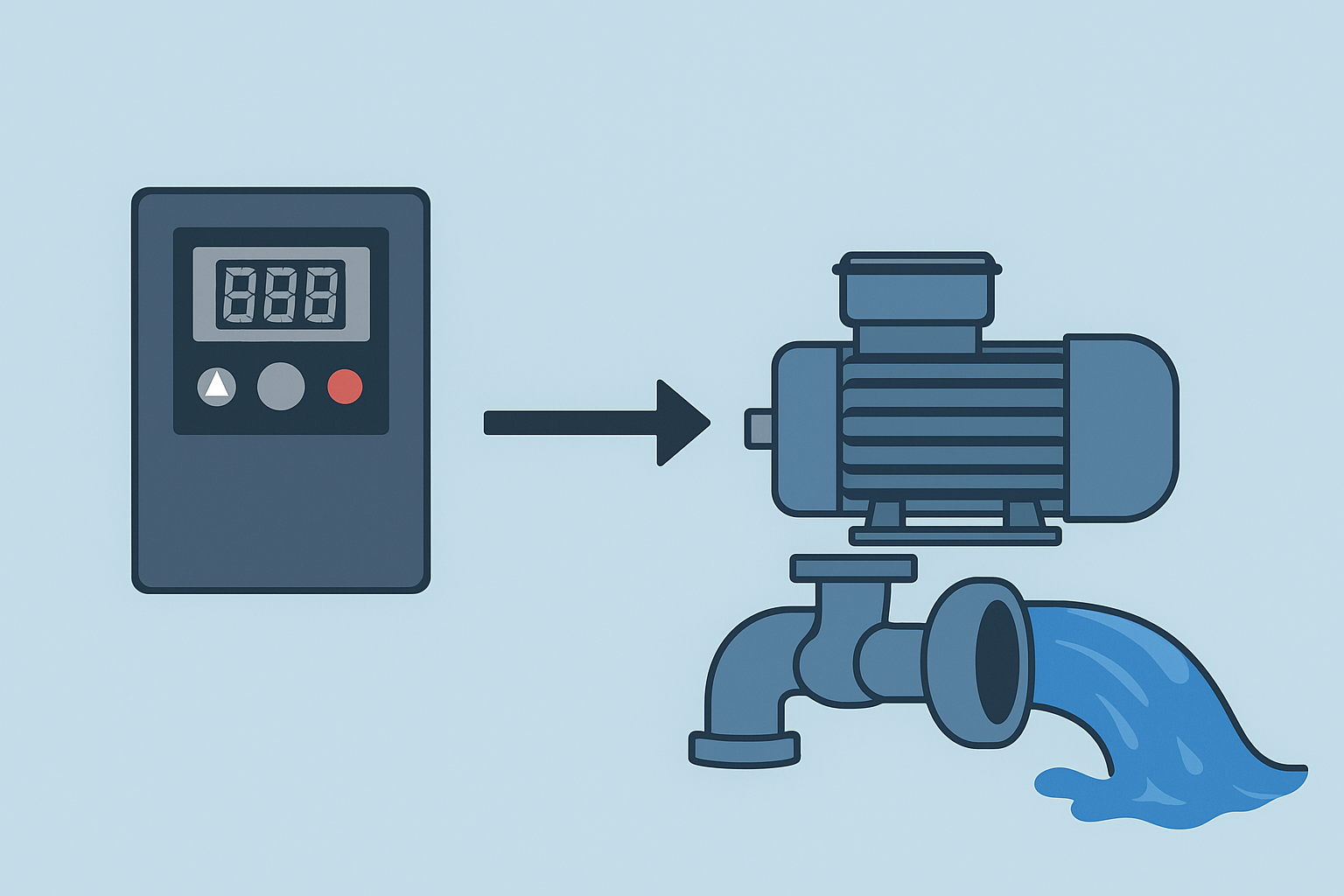

An inverter pump is any pump equipped with an inverter, also known as a Variable Frequency Drive (VFD). The inverter controls the motor's speed, allowing it to ramp up or slow down based on water demand, rather than just being a simple "on" or "off" switch.

Dive Deeper: The Brains Behind the Brawn

To really get it, you have to understand the difference between old pump technology and what an inverter brings to the table. For years, the standard pump was a simple, fixed-speed device. When pressure dropped, it switched on at 100% power. When the pressure was high enough, it switched off. This on-off cycle is inefficient, loud, and causes those annoying pressure surges and drops.

The Brains of the Operation: The Variable Frequency Drive (VFD)

The inverter, or VFD, is the brain. It's a sophisticated electronic controller that changes the frequency of the electricity going to the pump's motor. By changing the frequency, it can change the motor's speed with incredible precision. Think of it like a car's accelerator pedal instead of a light switch. You don't just floor it or turn it off; you give it exactly the amount of power needed to maintain your desired speed. This is what the inverter does for water pressure. Our RAFSUN pumps use high-efficiency Permanent Magnet Synchronous Motors (PMSM), which work perfectly with the VFD to deliver IE5 efficiency levels, the highest standard [^3].

Why Does Motor Speed Matter for an inverter booster pump?

Controlling the motor speed is everything. It's the key to both comfort and efficiency. I was talking with a major distributor of mine, Leon from South Africa, after he placed his first big order for our inverter booster pump models. He said his customers were amazed. They expected better pressure, but they were shocked by how quiet the units were and how much their electricity bills dropped. That's the VFD at work. A pump that's not constantly slamming on and off is a quiet pump. A pump motor that only runs as fast as it needs to is an energy-efficient pump.

Here’s a simple table to show the difference.

| Feature | Traditional Fixed-Speed Pump | Modern Inverter Pump |

|---|---|---|

| Motor Control | On/Off at full speed | Variable speed (0-100%) |

| Pressure | Fluctuates significantly | Stable and constant |

| Energy Use | High, with spikes on startup | Optimized, up to 50% less 1 |

| Noise Level | Loud, especially on startup | Super silent (<50dB) [^2] |

| Wear & Tear | High due to harsh starts/stops | Reduced, for a longer lifespan |

| System Complexity | Often requires a large pressure tank | Compact, all-in-one unit |

This intelligent control is the foundation of the modern inverter booster pump. It moves beyond simple power to smart performance.

So how does a standard booster pump fit into this?

You've heard of booster pumps, and maybe you've sold them for years. Their basic function is simple, but they are often the source of pressure problems when not managed by modern technology.

A booster pump is a device that increases the pressure of water from a source. It "boosts" existing pressure when it's too low for applications like showers, irrigation, or moving water to upper floors in a building. It's installed directly into the water line to perform this job.

Dive Deeper: From Brute Force to Finesse

The "booster" part of the name describes the pump's fundamental job: to add pressure. It takes water that's flowing at a low pressure and pushes it out at a higher pressure. This is a crucial function in countless settings.

Common Scenarios Where a Booster Pump is Needed

At RAFSUN, we manufacture pumps for a wide range of applications because low pressure is a universal problem. Our distributors sell our pumps into these common scenarios:

- Residential Homes: For fixing low municipal water pressure that results in weak showers and slow-filling appliances.

- Multi-Story Buildings: To ensure that apartments on the top floors have the same strong water pressure as those on the ground floor.

- Commercial Applications: Hotels, hospitals, and factories where consistent water pressure is essential for operations.

- Garden and Agricultural Irrigation: To provide enough pressure to run sprinkler systems effectively over a large area [^4].

The Limitation of a Traditional Booster Pump

The problem is that a traditional booster pump, without an inverter, is a blunt instrument. It's all muscle and no brain. It uses a simple pressure switch. When the pressure drops to a low point (say, 30 PSI), the pump kicks on at full power. It runs until the pressure hits a high point (say, 50 PSI), and then it shuts off. The water pressure you experience is constantly bouncing between these two points.

To make this less jarring, these older systems require a large pressure tank to act as a buffer. These tanks are bulky, take up valuable space, and can be a place where stagnant water allows bacteria to grow. This is what we wanted to solve.

The Perfect Marriage: Combining the "Booster" with the "Inverter"

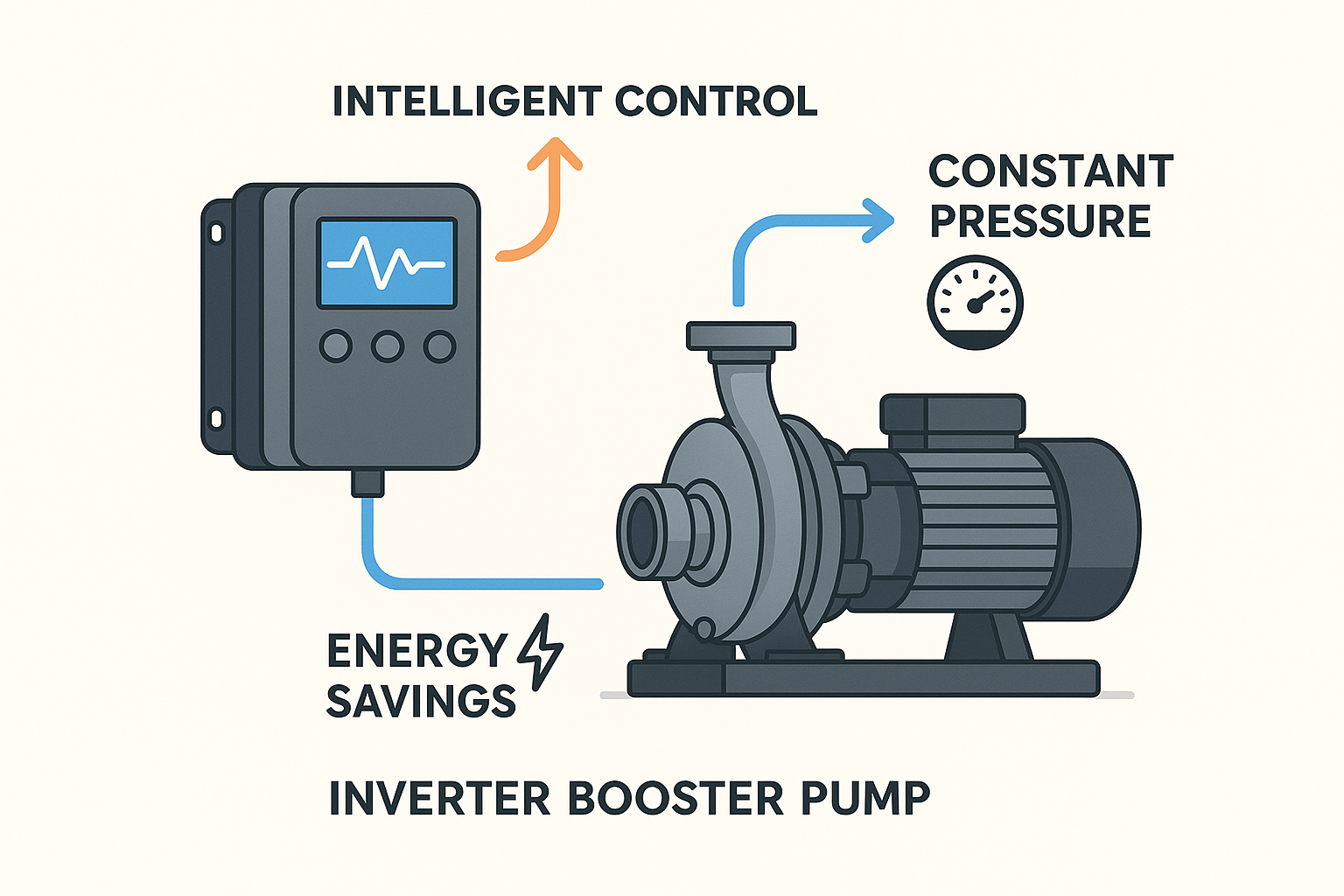

This is where the magic of the inverter booster pump happens. We've taken the raw power of a booster pump and combined it with the intelligent control of an inverter. The result is not just more pressure, but consistently stable pressure.

I often explain to my B2B clients that it’s the difference between a sledgehammer and a scalpel. Both can break through a wall, but one does it with brute force and a lot of collateral damage, while the other does it with precision, control, and finesse. The inverter booster pump is the scalpel for water pressure management. It precisely delivers the pressure you need, no more and no less, creating a comfortable and efficient system.

Why is the inverter component of an inverter booster pump so crucial?

The inverter is the heart of the system. Without it, the pump is just a blunt instrument. Understanding its purpose reveals the true value and technological superiority of an inverter booster pump.

The main purpose of the inverter (VFD) is to provide intelligent control. It adjusts the pump motor's speed to precisely match water demand, ensuring constant pressure, saving massive amounts of energy, and protecting the pump motor from stress for a longer lifespan.

Dive Deeper: Control, Efficiency, and Protection

When my R&D team—all 30+ of them—works on developing our next generation of pumps, their focus is on making the inverter do more. It’s the component that delivers the most value to the end-user and the most reliability for my distributors. Its purpose can be broken down into three core functions.

1. Constant Pressure Management

This is the most noticeable benefit. An inverter booster pump has a high-precision pressure sensor that constantly monitors the pressure in your pipes. When you open a tap, the sensor detects the slight drop in pressure and instantly tells the inverter to speed up the motor just enough to compensate and keep the pressure stable. When you close the tap, it slows the motor down. This happens so fast and smoothly that the user never feels a change. Our pumps allow for a wide range of pressure settings, so the user can dial in the exact pressure they want [^2].

2. Unmatched Energy Efficiency

This is the benefit that really impacts the wallet. There's a principle in pump physics that states power consumption is related to the cube of the motor's speed. In simple terms, this means a small reduction in speed leads to a huge reduction in energy use. For example, running a pump at 80% speed doesn't use 80% of the power; it uses closer to 50% of the power. Since a pump in a typical home rarely needs to run at full speed, the energy savings are massive over the life of the pump—up to 50% compared to old models 1. For commercial clients running pumps for HVAC or in high-rise buildings, this translates to thousands of dollars in savings.

3. Advanced System Protection

A good inverter is also a bodyguard for the pump. It protects the motor from all sorts of problems that cause traditional pumps to fail. This is a critical selling point for a knowledgeable B2B buyer who values reliability and low return rates. Our RAFSUN pumps, for example, have 14 unique protection functions [^5]. We also seal our main circuit boards in a potting compound to protect them from humidity and vibration, which is crucial in tough environments [^4].

Here are some of the most important protections:

| Protection Feature | What it Does | Why it Matters for an inverter booster pump |

|---|---|---|

| Dry-Run Protection | Shuts down the pump if it senses no water. | This is the number one killer of pumps. Dry-running burns out the motor and seals. This feature prevents catastrophic failure. |

| Overload Protection | Monitors the electrical current and shuts down the pump if it's too high. | Protects the motor from burning out due to an electrical fault or a blockage. |

| Blockage Protection | Tries to restart a few times if the impeller is jammed. If it can't, it shuts down. | Prevents mechanical failure and damage to the motor and pump. |

| Over/Under Voltage | Protects the sensitive electronics from damage due to an unstable power grid. | This is essential for our clients in over 150 countries, many of which have fluctuating power supplies. |

These protections are not just features; they are a promise of a longer, more reliable service life for every inverter booster pump we ship.

Can the inverter itself pump water, or does it need the pump?

This is a fantastic technical question I get a lot from engineers and new importers. It's easy to get confused. Let me clear this up: the inverter is the brain, not the muscle.

No, an inverter cannot pump water by itself. The inverter is an electronic controller (a Variable Frequency Drive). It controls the speed of the electric motor, and the motor is what physically drives the pump mechanism (impellers) that moves the water.

Dive Deeper: A Three-Part Team for Perfect Water Flow

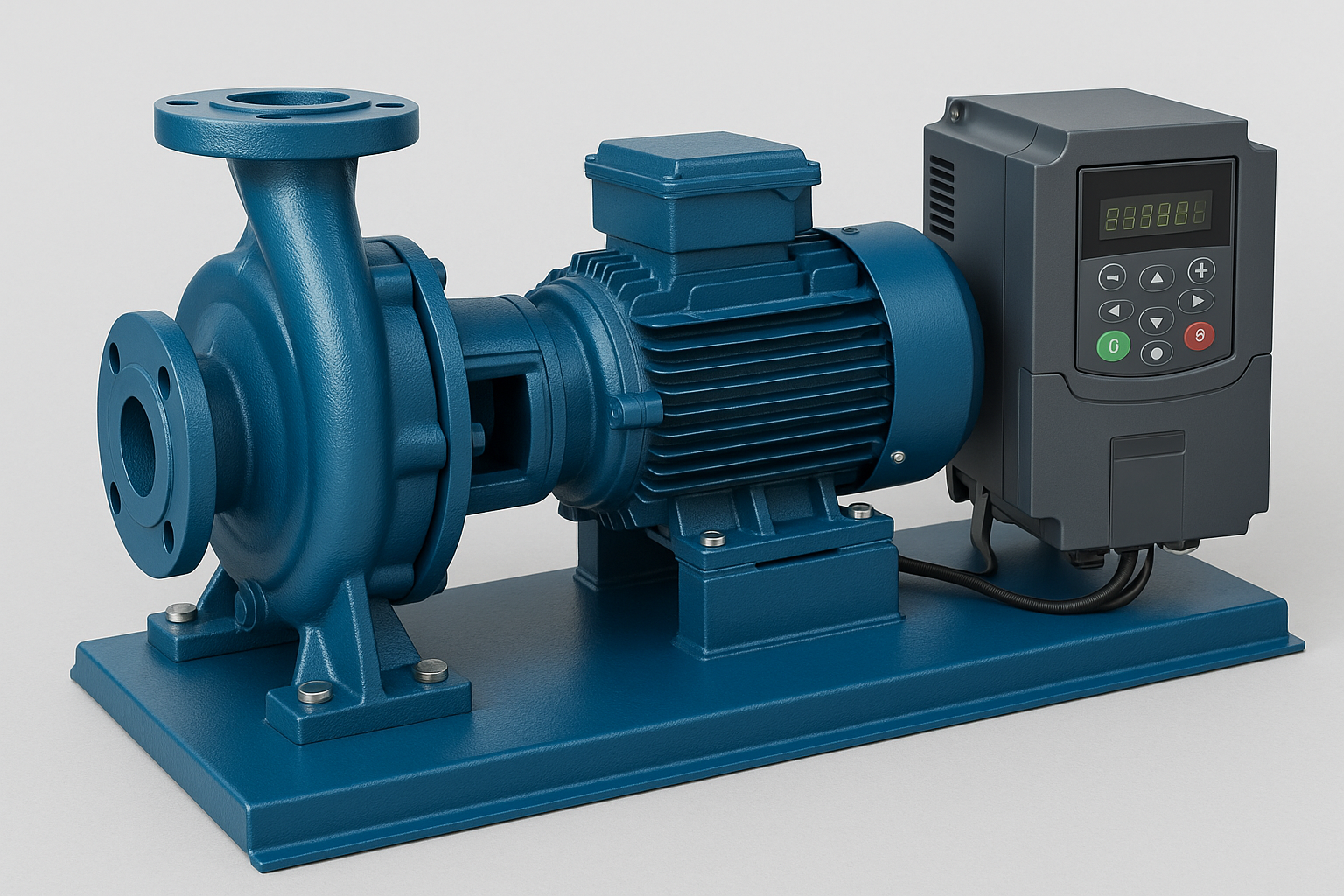

To truly understand how an inverter booster pump works, you have to see its three main parts as a team. Each part has a distinct and vital job. If one fails, the whole system fails. I like to use the analogy of a professional race car team when explaining this to my partners.

The Pump, The Motor, and The Inverter: A High-Performance Team

-

The Pump (Wet End): The Chassis and Wheels

This is the part of the unit that actually touches the water. It consists of the housing, the inlet and outlet, and the impellers that spin to propel the water. Like a car's chassis and tires, it must be strong and durable to handle the physical work. That’s why we use premium materials like corrosion-resistant AISI304 stainless steel or robust brass for our impellers, ensuring they last for years [^5][^6]. -

The Motor: The Engine

This is what provides the raw power. The motor takes electrical energy and converts it into the rotational force needed to spin the pump's impellers. We use high-efficiency Permanent Magnet Synchronous Motors (PMSM) in our RAFSUN pumps. Think of this as a modern, high-performance racing engine—it delivers more power and torque with less fuel (electricity) than older engine designs [^4]. -

The Inverter (VFD): The Expert Driver

This is the star of the team—the professional driver. The driver has the car and the engine, but their skill is what wins the race. The driver takes in information from the track and the car's sensors and then uses the accelerator, brakes, and steering with precision to get the maximum performance. The inverter does the same thing. It takes information from the pressure sensor and tells the motor exactly how fast to run. It’s the intelligence that harnesses the motor's power and the pump's strength to deliver a perfect, winning performance.

The Evolution to an Integrated Inverter Booster Pump

In the past, and still in many large industrial settings, these three components are purchased separately. You’d have a big pump, a separate motor, and a huge VFD controller in a wall-mounted panel. But the true innovation for the residential and commercial markets has been integration.

At RAFSUN, we've engineered these three parts to work together seamlessly in a single, compact, and easy-to-install unit. This integrated design is a core part of what makes a modern inverter booster pump so effective. The components are perfectly matched for optimal performance. For resellers like Leon, this is a huge advantage. They can offer their customers a complete, factory-tested solution that is far easier to install and more reliable than a system pieced together from different manufacturers. Our "Pump Link Mode," which allows two of our pumps to communicate and work together for double the output or to alternate duties, is a perfect example of this deep integration in action [^2].

Will a VSD inverter booster pump guarantee an increase in my water pressure?

This is the bottom-line question. You're buying a booster pump to solve a pressure problem. The short answer is an emphatic yes. But the quality and reliability of that pressure increase are what really matter.

Yes, an inverter booster pump is specifically designed to increase water pressure. Its primary function is to boost insufficient pressure to a desired, constant level. The "inverter" part ensures this increased pressure is perfectly stable and not fluctuating, providing a superior user experience.

Dive Deeper: From Low Pressure to Perfect, Stable Flow

An inverter booster pump doesn't just increase pressure; it transforms your entire water system. It takes an unreliable, low-pressure supply and turns it into a luxurious, high-pressure flow that you can count on every time you open a tap.

How an Inverter Booster Pump Solves Low-Pressure Problems

When you look at the technical data for our pumps, you'll see specifications like 'H.Max' and 'Q.Max'. These numbers are the guarantee.

- H.Max (Maximum Head): 'Head' is the technical term for the vertical height a pump can push water, which directly translates to pressure. For example, our BWE-1500 model has an impressive H.Max of 66 meters [^6]. This means it has the raw power to generate very high pressure, easily capable of supplying a multi-story building.

- Q.Max (Maximum Flow): This tells you how much water the pump can move, usually in cubic meters per hour (m³/h). Strong pressure is useless if the flow can't keep up when multiple taps are open. A model like our BWD-2200, with a flow of 8m³/h [^4], can comfortably supply a large home with several bathrooms and appliances running at once.

Factors That Determine the Final Pressure

As a manufacturer, I believe in being honest with my clients. The pump is the heart of the solution, but the entire system has to be sound. I always advise my distributors to consider these factors to ensure their customers' success:

- Correct Pump Sizing: Choosing the right pump is the most critical step. You must match the pump’s head and flow capabilities to the building’s size and a family's water demand. Our team works closely with our distributors to help them select the right models from our catalog for their specific market needs.

- Existing Pipe Condition: A powerful inverter booster pump can't work miracles if the pipes are old, clogged with scale, or too narrow. Healthy pipes are essential for good flow.

- System Leaks: Even a tiny, hidden leak in the plumbing will constantly seep pressure, forcing the pump to work harder and wasting energy.

The RAFSUN Advantage: Engineering a Guarantee

This is where choosing the right manufacturing partner makes all the difference. At RAFSUN, we don't leave performance to chance. We engineer it into every unit.

- Decades of R&D: Our team has secured over 100 technical patents in intelligent pump technology. This isn't just a number; it represents years of solving complex engineering challenges to make our pumps more powerful, efficient, and reliable 1.

- Rigorous Quality Control: We operate under a strict quality system (IQC, LQC, PQC, OQA). Every component is checked, every assembly is monitored, and every finished pump is tested.

- Extreme Durability Testing: We subject our pumps to brutal conditions to ensure they survive in the real world. This includes 144+ hours of continuous salt spray testing to check for corrosion and 1000+ hours of UV resistance testing for parts exposed to sunlight 1.

When we ship one of our 300,000+ units each year, we know it will work. When a distributor like Leon sells a RAFSUN inverter booster pump, he can be confident that he is providing a real, guaranteed solution to his customer's water pressure problems.

Conclusion

In short, an inverter booster pump is the smart choice for anyone seeking constant pressure, major energy savings, and long-term reliability. It's the modern, powerful, and efficient solution to low water pressure.